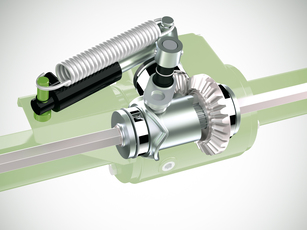

Direct drive:

All drive components are safely protected against dust and dirt thanks to the closed design, and are lubricated with grease. A large hex shaft and selfcentring crosspiece joints are efficient drivers of the rotors. The maintenance-free system has proven its worth on tedders a thousand times over, and features a direct, straight drive train. The system is also easily accessible and is therefore very maintenance friendly.

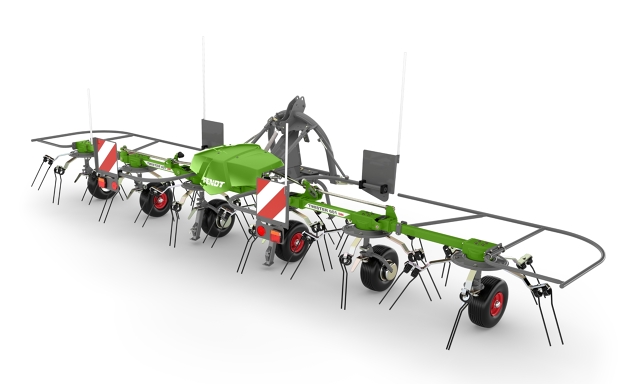

Setting in motion:

Smart features which make the Fendt Twisters the efficient and well-designed machines that they are, can also be found on the rotors’ wheels. They have been positioned so that there is only a small gap to the tines at the lowest point on the ground. This gives the Twisters excellent ground following, and prevents contamination of the forage. The wheels also have winding protection plates in the rims, which keep grass away from the rim.