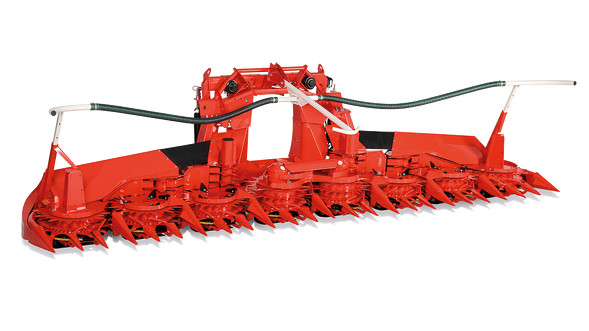

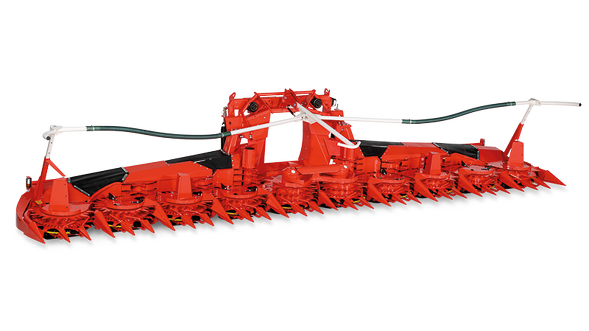

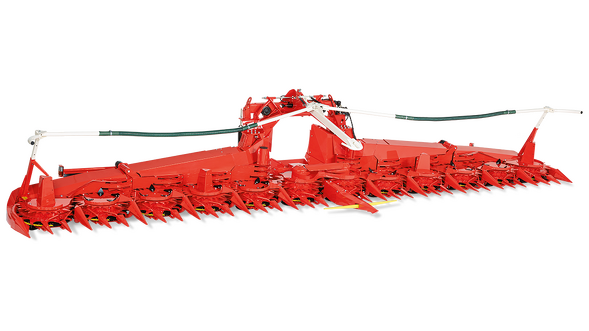

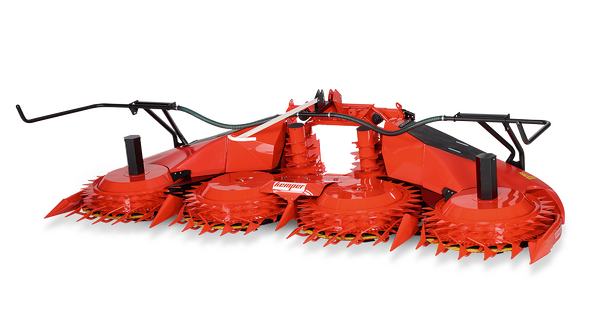

More attachments, more applications

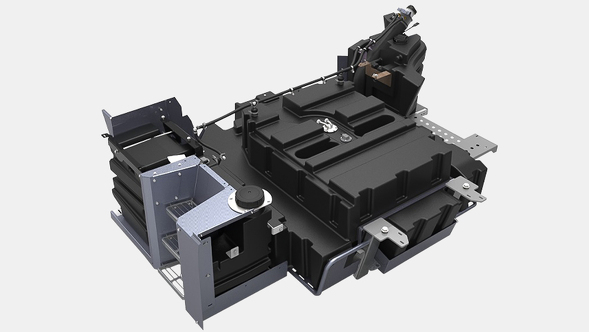

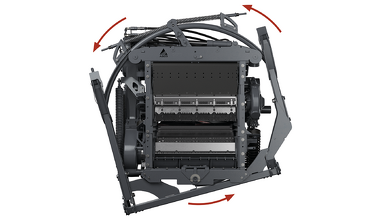

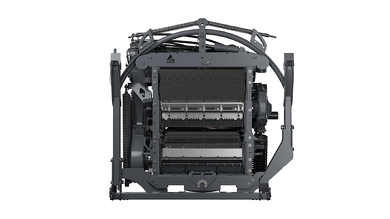

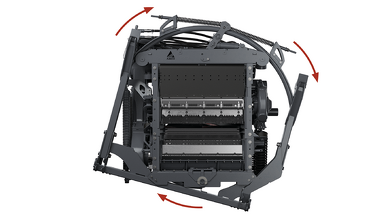

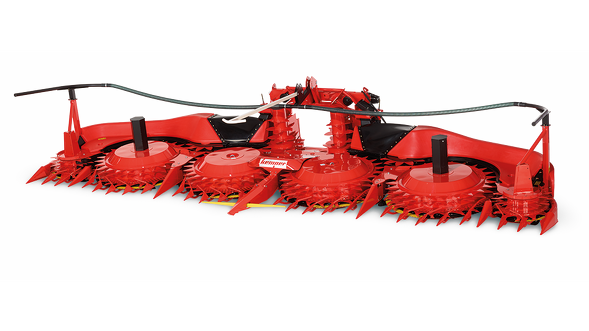

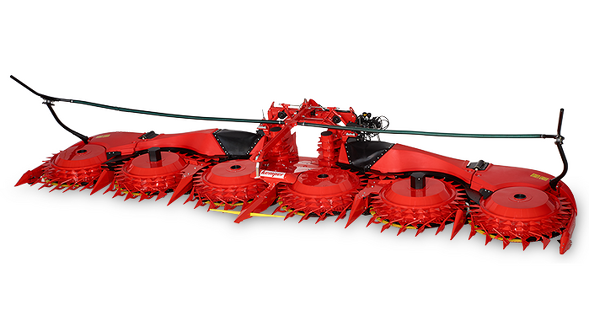

The pendulum frame of the Fendt Katana has an extended pendulum angle of up to 14° and ensures even better ground hugging of the attachments. The Katana pendulum frame as well as the touch sensors of the attachments automatically adapt to strongly changing ground contours. Because the pendulum frame has a central pivot point, the crop flow remains uniform even when the attachment is at an angle. All attachments are placed very close to the vehicle. This reduces the front axle load and protects the ground.