Products & Solutions

Agricultural Machinery

back

to Overview

Tractors

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hp

Fendt 1000 Vario

Fendt 1000 Vario

from 291 kW / 396 hp to 380 kW / 517 hp

Fendt 900 Vario MT

Fendt 900 Vario MT

from 279 kW / 380 hp to 317 kW / 431 hp

Fendt 900 Vario

Fendt 900 Vario

from 217 kW / 296 hp to 305 kW / 415 hp

Fendt 700 Vario Gen7

Fendt 700 Vario Gen7

from 149 KW / 203 hp to 223 kW / 303 hp

Fendt 700 Vario Gen6

Fendt 700 Vario Gen6

from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 600 Vario

Fendt 600 Vario

from 110 kW / 149 hp to 154 kW / 224 hp

Fendt 500 Vario

Fendt 500 Vario

from 91 kW / 124 hp to 120 kW / 163 hp

Fendt 300 Vario

Fendt 300 Vario

from 83 kW / 113 hp to 104 kW / 142 hp

Fendt 200 Vario

Fendt 200 Vario

from 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 VFP Vario

Fendt 200 V/F/P Vario

from 58 kW / 79 hp to 91 kW / 124 hp

Telehandler

Fendt Cargo T740

Fendt Cargo T740

100 kW / 136 hp

Fendt Cargo T955

Fendt Cargo T955

123 kW / 171 hp

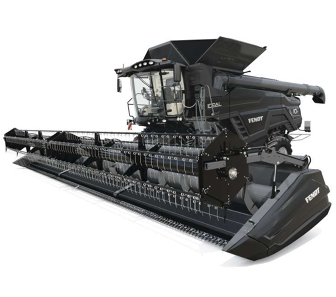

Combines

Fendt IDEAL

Fendt IDEAL

from 336 kW / 451 hp to 581 kW / 790 hp

Fendt C-Series

Fendt C-Serie

from 225 kW / 306 hp to 265 kW / 360 hp

Fendt L-Series

Fendt L-Serie

from 192 kW / 260 hp to 225 kW / 306 hp

Fendt CORUS 500

Fendt CORUS 500

from 136 kW / 185 hp to 192 kW / 260 hp

Forage wagons

Fendt Tigo XR/VR/PR

Fendt Tigo

XR/VR/PR

XR/VR/PR

Fendt Tigo MS/MR/MR Profi

Fendt Tigo

MS/MR/MR Profi

MS/MR/MR Profi

Balers

Square Balers

Fendt Square balers

Rotana F

Fendt Rotana F

Rotana V

Fendt Rotana V

Rollector

Fendt Rollector