Fendt Momentum

Configurator

Read Brochure

The potential for maximizing yield all starts with putting the seed in the ground and the details make all the difference, like ensuring accuracy no matter the field condition, or minimizing compaction, or simply covering more acres when they need to be covered.

Momentum Models

| 16 | 24 | 31 | 32 | 36 | 48 | |

| # of Rows | 16 | 24 | 31 | 32 | 36 | 48 |

| Row Spacing | 30" | 20", 22", 30" | 15" | 15" | 20", 22" | 15" |

The Vertical Contouring Toolbar (VCT) compensates height differences of 52 inches. Rolling contours, terraces, and uneven ground don't mean you need to sacrifice accuracy with Momentum.

The Fendt Momentum planter equipped with Load Logic provides you with a solution to the compaction issues that are otherwise created in non-optimal conditions.

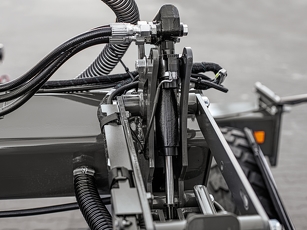

Fendt Momentum’s Load Logic system, automatically transfers weight off the row units of the planter by lifting and adjusting the planter frame to minimize row unit downforce.

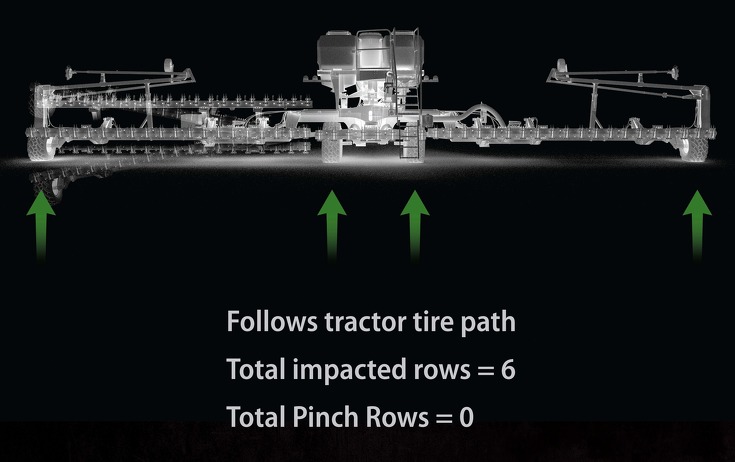

The system has two automatic modes of operation, Load Balance, which distributes weight across the entire frame, or Controlled Traffic, which shifts compaction pressure to follow tractor path.

The tire inflation system is part of the LoadLogic weight management system. Various sensors help automatically adjust the tire pressure.

Not only are these automatic weight distribution adjustments to the planter frame and tire pressures assisting in reducing compaction, but so too is the tire configuration. The planter features in line center tandem wheels, which follow the affected row path already created by the tractor tires, thereby controlling traffic through the field and limiting compaction. This design, along with its front of frame mounted tire configuration, completely eliminates pinch rows, whereas conventional row unit planters have upwards of 6 compaction affected pinch rows.

Less time filling, more time planting – 130 bu. seed tank capacity and 1,000 gallon liquid fertilizer.

More capacity means less stopping, but managing that extra weight is key. Momentum not only adds capacity but also limits its negative effects through its in-line center tandem wheel design and its Load Logic weight management system.

The Fendt Momentum planter offers an optional 1,000 gallon liquid fertilizer system, allowing you to cover more ground and make fewer stops. Single band Precision Planting Conceal options can be equipped directly from the factory.

Higher capacity means fewer fills throughout the busy planting season, the Fendt Momentum features twin 65 bu. seed tanks for higher capacity and is easily accessed with a wide platform.

The Fendt Momentum planter offers an optional 1,000 gallon liquid fertilizer system, allowing you to cover more ground and make fewer stops. Single band Precision Planting Conceal options can be equipped directly from the factory.

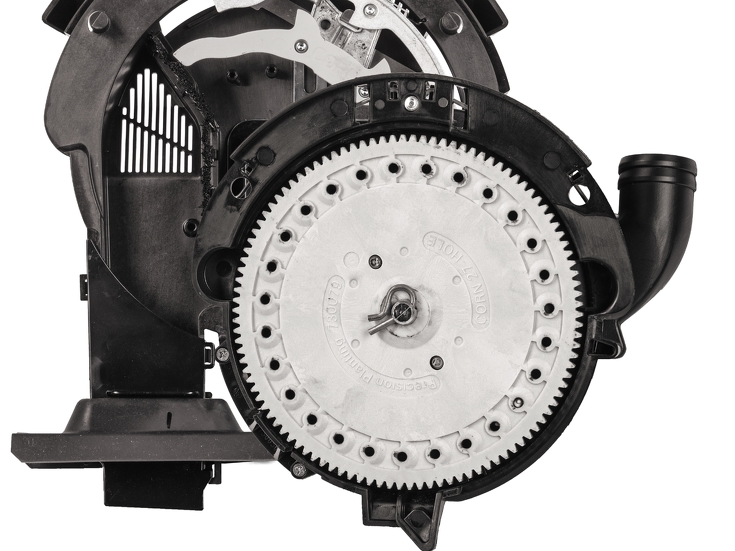

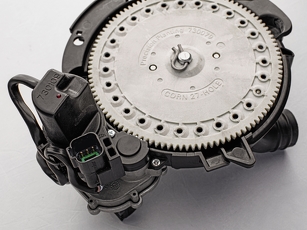

The vSet is easy to use, incredibly accurate and easy to maintain. It has an extremely high singulation accuracy.

The Conceal fertilizer application system is equipped with a single-sided application knife. The application knife is located between the depth control wheel and the double disc coulter. The application point is 3 inches beside the furrow at a depth of 0.75" to 1.5". As Conceal works directly next to the seed furrow, the application is perfectly placed next to the seed furrow, regardless of the terrain and cornering. A maximum of 71 GPM can be applied.

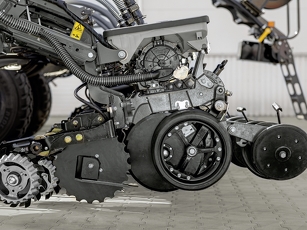

The row unit consists of the metering unit, seed tube, gauge wheels, residue manager, tillage disc and other components. With this modular system, you can select the parts to give you the right solution whatever the conditions.

Creates a specific downforce for each row for the right standing pressure for different soil types and planting conditions.

The row units are electrically driven. The vDrive is marked by its outstanding reliability and precision.

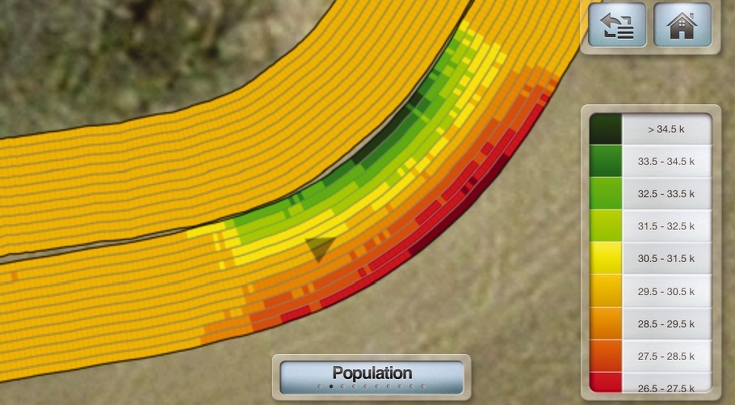

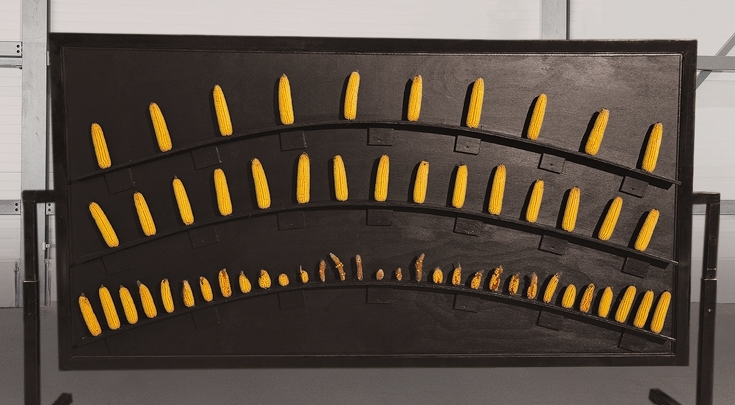

Reduces yield losses due to emergence variations in undulating rows and headlands. Conventional technology below; Fendt MOMENTUM with curve compensation above.

The picture below shows the influence of contours on the ear size when maize planting. Without curve compensation, the inner and outer rows show losses.

A variety of row unit residue manager options are available to tailor Momentum to your field's needs.

Choose from rubber or steel closing wheel options.

Monitor all planter functions and individual row unit performance in real time with the 20/20 Gen3 SeedSense® monitor system, which comes standard on all Fendt Momentum planters. , 20/20 SeedSense tells you what you need to know about population, skips, doubles, speed, row unit ride, down force and ground contact. It enables you to seed precisely, maintain depth, avoid compaction and troubleshoot mechanical problems.

Fendt Momentum

Configurator

Read Brochure

Danmark (Denmark)

Danmark (Denmark)  Deutschland (Germany)

Deutschland (Germany)  Eesti (Estonia)

Eesti (Estonia)  España (Spain)

España (Spain)  France (France)

France (France)  Italia (Italy)

Italia (Italy)  Lietuva (Lithuania)

Lietuva (Lithuania)  Nederland (Netherlands)

Nederland (Netherlands)  Norge (Norway)

Norge (Norway)  Österreich (Austria)

Österreich (Austria)  Polska (Poland)

Polska (Poland)  Suomi (Finland)

Suomi (Finland)  Sverige (Sweden)

Sverige (Sweden)  United Kingdom

United Kingdom  Україна (Ukraine)

Україна (Ukraine)  North America

North America  Brasil (Brazil)

Brasil (Brazil)  South Africa

South Africa  Australia

Australia