The Fendt Tigo VR series comprises two models – the Fendt Tigo 65 VR with a capacity of 38 m³ and the Fendt Tigo 75 VR with a capacity of 44 m³ (DIN-standard spec). The blades can cut up to 37 mm and their shape results in a long and shearing cut. Both machines have the multifunctional bulkhead with VarioFill as standard. The Fendt Tigo VR series combines the loading unit familiar from the Fendt Tigo PR with the mounting measures from the Fendt Tigo XR:

- Transportation width: 2,75 meters

- Transportation Length: 8,77 meters (Fendt Tigo 65 VR)/ 9,77 meters Fendt (Tigo 75 VR)

- Transportation Height: 3,92 meters (Fendt Tigo 65 VR)/ 4 meters Fendt (Tigo 75 VR

It comes with a variety of different tyre options. Special chassis or drilled axles are also available on request.

Packing a punch in the swath

With a swinging pick-up working width of 2 meters (DIN-standard spec), the Fendt Tigo suits large farms that rely on self-mechanisation. For a large throughput, the pick-up of the Fendt Tigo VR comes with 7 rows of tines. The larger width means more material can be picked up and makes it easier to drive into the swath. The wide pick-up ensures a high impact even when cornering. The hydraulic drive also promises greater flexibility, steplessly adapting the speed of the pick-up from 70 rpm to 150 rpm depending on the crop and conditions.

The main drive train is covered at 2,500 Nm. The Fendt Tigo VR also comes with the option of two or three feed rollers. This means the unloading process is more efficient, and the wagon can get back to the field faster.

Flexible and sharp – every time

Customers also have the chance to purchase the FlexSharp knife sharpener, a familiar feature of the Fendt Tigo XR, for their new Fendt Tigo VR. FlexSharp lets you sharpen the knives in the loading wagon itself, so you don't have to remove individual blades and grind them by hand. Because you can adapt the series of holes for the sharpener and because it is separate from the loading wagon, this sharpener is also compatible with knives from different customer machines and round or square baler knives.

Customers can also opt for a second set of knives, as well as the bracket for them, which is pre-mounted on the beam of the cutting unit. The knives can be exchanged out on the field if necessary, which reduces downtime.

Rock-steady even on slopes

The optional self-levelling feature Fendt Stability Control ensures safe use on the slope and stable road handling. No matter what the load, the levelling system always provides full suspension to counteract rocking movements. Loading during the harvest is consistent and makes maximum use of the Fendt Tigo's full capacity.

Versatile for any type of work

The Fendt Tigo VR can also be used to transport other goods after the grassland harvest. You can now order machines without feed rollers with a reversible scraper floor. Benefits include making full use of the loading space while transporting square bales by gradually reversing.

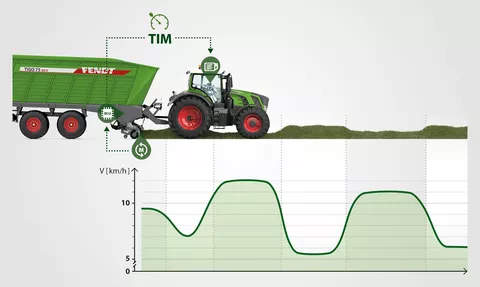

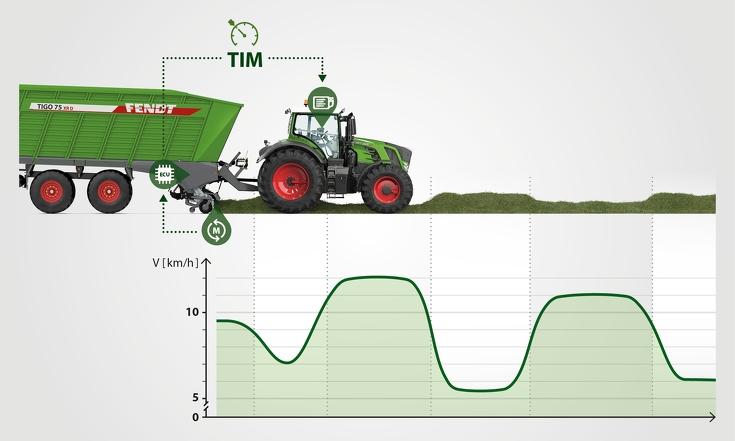

The loading wagon steers the tractor

The fully automatic throughput control can now be done on the Fendt Tigo VR via TIM (Tractor Implement Management). The combi wagon regulates the driving speed of the tractor, depending on the pickup load and its speed. As a result, as the filling process is underway, the tractor automatically slows down with a large swath load and speeds up again with a small swath load. The Fendt Tigo VR combi wagon always works productively by self-regulating and self-optimising. This assist feature is also a great help for the driver, who can fully concentrate on the loading process.