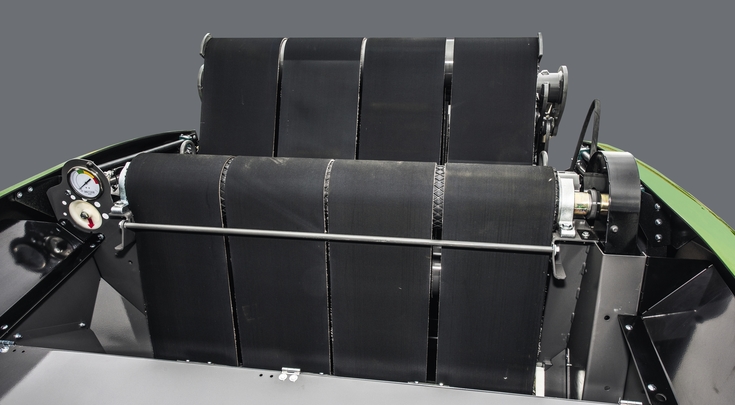

In order to guarantee bale rotation in all conditions, all variable Fendt round balers have an Additional Drive System ADS. The four infinite belts and the upper drive roller are reliably driven by another drive roller directly below them. The wide wrapping angle produces powerful friction between the belt and roller and permanently prevents slippage.

Consistent bale density due to increase in pressure.

Bale chamber and belt hold the key

CPS provides constant pressure

For best results, it is vital that the bale density is properly controlled. All Fendt round balers with variable chamber therefore have the Constant Pressure System (CPS). With increasing bale diameters, this system ups the pressure to ensure a consistent bale density throughout the baling process. A consistent bale density is generated by achieving a balance between mechanics and hydraulics. As a first step, the belt tension caused here by large springs ensures a perfect start to the bale with a fast start speed and highly compacted inner layers. As the bales grow, the hydraulics take over the tensioning of the belts. Two cylinders connected to the closed hydraulic system proportionally increase the belt tension whilst the bales grow, so that the set density is reached. The outer layers are therefore perfectly compressed.

Very strong belts

Four infinite rubber and synthetic belts ensure an optimal grip on the crop, and apply plenty of pressure on the bales thanks to their exceptional traction. Two special synthetic fabric liners mean that the belts can withstand high tensile loads. These liners are produced separately with long excess lengths. This avoids any problematic joins.

Our bale chamber: Perfect bales, every time.

Firmly under control

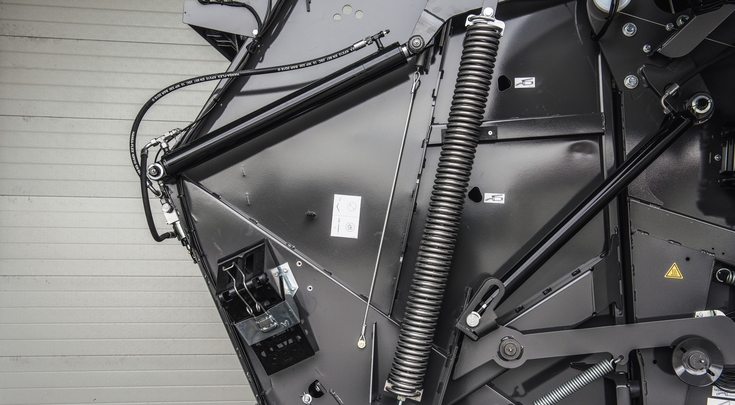

The secret of the perfectly-compacted and even bales which are consistently compressed using Fendt round balers lies in the tail gate. It has been designed to be particularly robust, because it has to be able to withstand exceptionally high loads. The patented flexible suspension offers outstanding benefits.

Tail gate in motion

The tail gate on the Fendt round baler ensures perfect compaction throughout the baling process. At the start of the bale, the tail gate is the top position to form a clean core. As the diameter grows, the tail gate moves mechanically downwards. The tail gate slides to move the bales towards the rear. This reduces the pressure on the feed section. This maintains the highest output rates with perfectly formed bales. The even pressure distribution also reduces wear on the components.