Because the number one is also digitally far ahead.

The Fendt 900 Vario stands for unique flexibility and impresses with its low fuel consumption. With the FendtONE digital platform, you can plan, organise and document your work in the simplest way possible.

| kW | HP | |

| 930 Vario | 217 | 296 |

| 933 Vario | 239 | 326 |

| 936 Vario | 261 | 355 |

| 939 Vario | 283 | 385 |

| 942 Vario | 305 | 415 |

Rated power ECE R 120

Special. Better. Fendt 900 Vario Spotlights.

Here you will find the special Fendt solutions, the Fendt Spotlights, which make the difference and simply make your work better every day.

Show more details

Reverse drive

- Extends the range of applications

- Quick 180° rotation of the entire operator's platform thanks to pneumatically assisted turning device

- Optimum view of implements at the rear

- Quick 180° rotation of the entire operator's platform thanks to pneumatically assisted turning device

- Optimum view of implements at the rear

Smart Farming Solutions

FendtONE platform

Seamless connection of machine and office.

Bonnet camera

Self-cleaning air filter

Fendt iD low-speed concept

Fendt Stability Control

Integrated VarioGrip tyre pressure control system

Intelligent VarioDrive

Two hydraulic pumps with a flow rate of 430 l/min:

- Supply of two consumers with different pressure and oil flow rates possible

FendtONE: Intuitive operation and unique connection between machine and office.

The new FendtONE driver's workplace (onboard) for more functionality, customisation and ergonomics. With FendtONE offboard, planning and administrative functions (team, machine, field and job management) can be carried out from anywhere.

3L joystick with reverse button

Colour coding of the different function groups, also for function reassignment

up to three displays available: 10" dashboard, 12" terminal on the armrest, 12" terminal retractable into the cab roof

Flexible key assignment via the Individual Operation Manager (IOM)

new armrest with Fendt-known elements

Four equipment variants for more individualisation:

Power, Power+, Profi and Profi+."

In order to design the workstation in the best possible way according to your requirements, you can choose between four equipment variants: Power, Power+, Profi, Profi+.

In each case, you can choose between Setting 1 or Setting 2:

In each case, you can choose between Setting 1 or Setting 2:

*All illustrations show standard equipment and optionally available front linkage.

More efficiency - performance combined with economy.

Fendt iD low-speed concept

- Perfect combination of all vehicle components such as engine, transmission, fan and hydraulics and all auxiliary consumers to ideal engine speeds

- Reach the highest torque even at low engine speeds

- Permanently low fuel consumption

- Extended service life

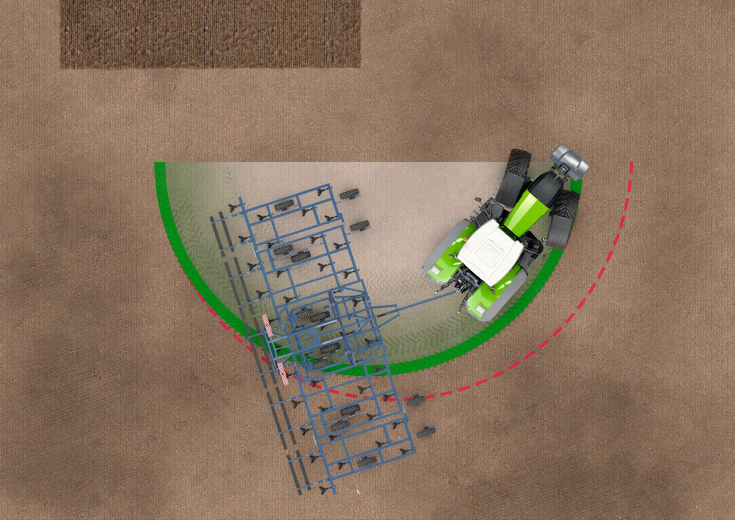

Intelligent VarioDrive

- Independent drive of front and rear axle

- No manual all-wheel drive necessary

- Optimum engine/transmission matching in conjunction with Fendt iD low-speed concept

- Smallest possible turning circle due to pull-in turn effect

- No need to change driving ranges

- Transmission oil change every 2,000 operating hours

- No special oil necessary

Self-cleaning air filter

- Air filter is blown out during work by means of short air blasts

- Reduced maintenance effort

Electrically adjustable comfort rear-view mirrors

- Electrically adjustable rear-view and wide-angle mirrors

- Telescopic mirror holders

- Locking system

- Upper link lifting aid

More grip - Unrestricted traction.

Integrated tyre pressure control system VarioGrip

- Fully integrated tyre pressure control system with on-board valve and air guidance technology

- No risk of air lines being torn off thanks to protected design

- Simple operation via the terminal

Ready for the future. With smart solutions from Fendt.

Smart Farming Modules - individually selectable

- Four modules from which to choose as required

- Each module consists of a basic package with all necessary start-up applications

- Can be extended as required with options: Fendt Contour Assistant, Fendt TI Headland*, Fendt Section Control, Fendt Variable Rate Control and many more

- Regular software updates to keep you up to date with the latest technology

Extended range of functions for Fendt Section Control and Fendt Variable Rate Control

- Automatic section control for up to five implements or application units simultaneously, support for up to 144 sections

- Variable control of the application rate per part-width section (zone) when the implement is suitably equipped, support for up to 144 zones