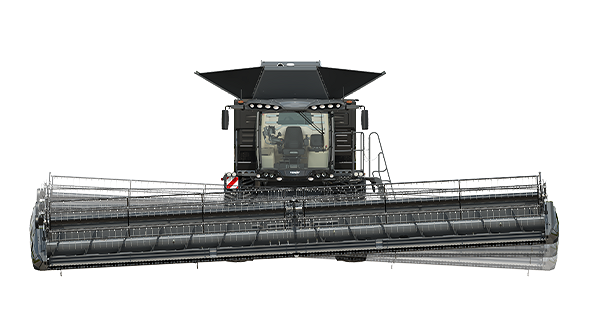

Redefine your harvest with our combine harvester.

Models

| IDEAL 7 | 350 kW | 476 hp |

IDEAL 8 | 396 kW | 538 hp |

IDEAL 9 | 476 kW | 647 hp |

IDEAL 10 | 581 kW | 790 hp |

Fendt Virtual Showroom

The detailed 3D all-round view gives you insight into selected features such as the cab, cutterbar, grain tank and more.

Use the arrows to click your way through the Fendt Forum to the interior of the machine.

Your IDEAL Story

Combine customers from around the world tell their IDEAL Story

Fendt IDEAL combine harvester

More output.

More performance.

It's more user friendly.

It is time for new dimensions.

PowerFlow headers

Always in the right position

Powerful hydraulics

Fendt Autodock™ crop elevator

Dust extraction on the crop elevator

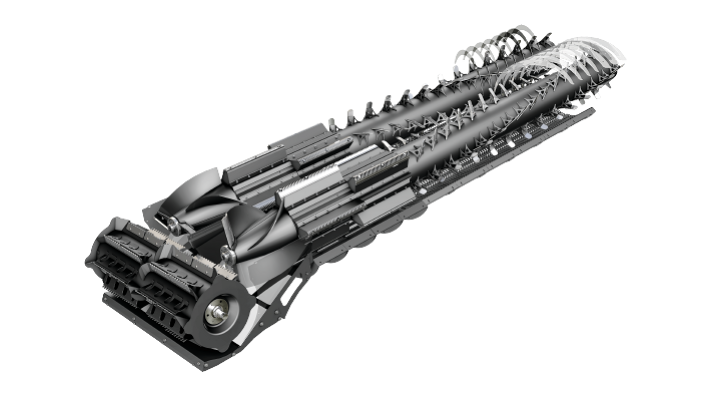

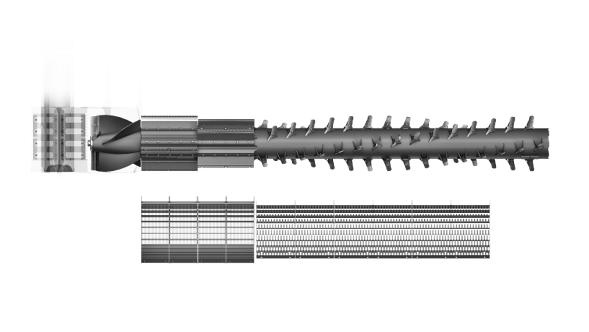

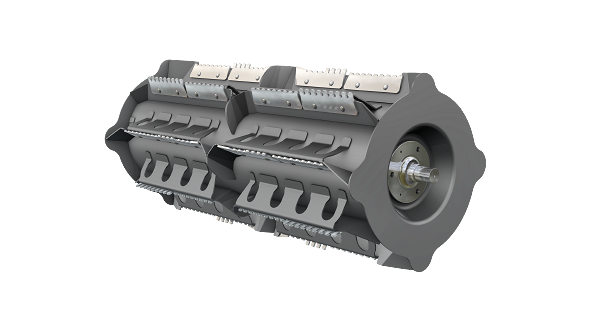

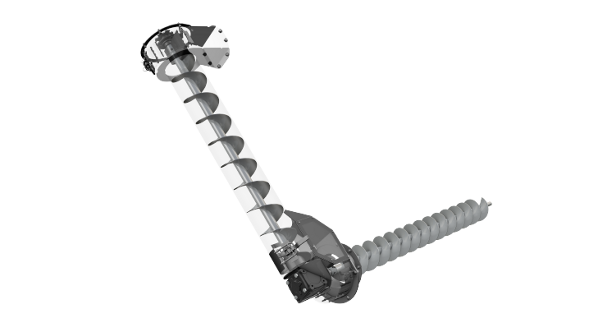

The Helix processor – simply unique

RotorFeeder feeding drum

crop from below to the rotors, guaranteeing the best threshing results. The RotorFeeder speed is automatically controlled in proportion to the rotor speed – always at 70% of the rotor speed. Because the speed is adjusted to best match the rotor speed and the large transfer area, the straw is kept intact. The RotorFeeder also uses far less power during this process. A constant flow of crop is guaranteed by the optimal transfer.

Gentle feed, low power requirement

The height of each rotor tine is 140 mm. Perfectly separated grain without damaging the product too much in too confined a space. In turn you get high straw quality and best threshing at low power. The threshing system is also distinguished by its simple configuration. The operator only needs to change the rotor speed range and the concave clearance.

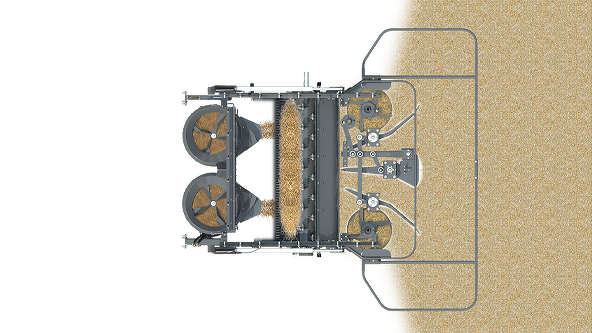

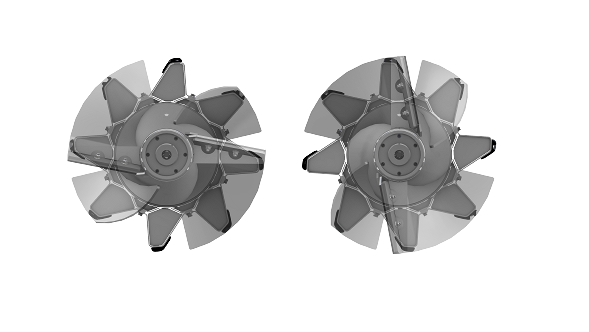

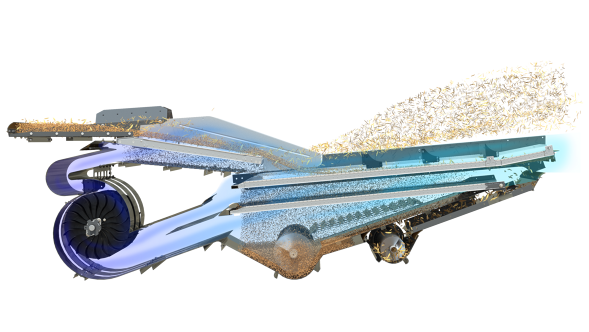

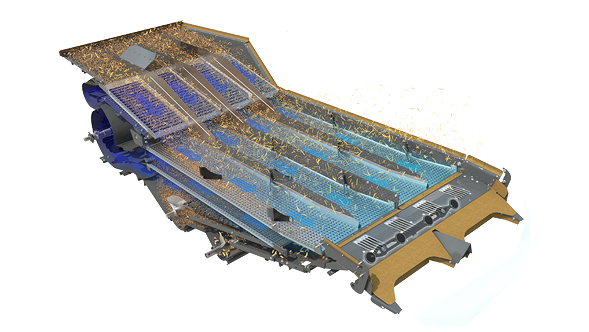

Triple fan

Separate post-threshing

Superior cleaning

The Fendt IDEAL is built for exceptional cleaning results

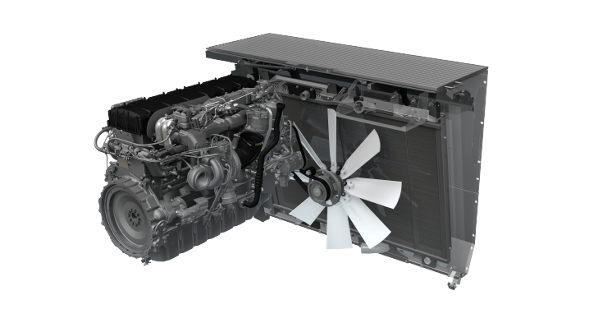

Engines & reversible fan

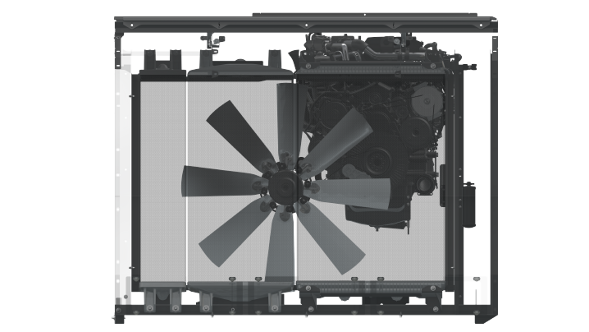

MAN and AGCO Power engine

Revolutionary AirSense® Cooling

cooling area of 2.7 m². The air is extracted centrally through a radiator grille on the top side of the Fendt IDEAL. Depending on the temperature and time, the fan automatically changes its direction of rotation and reliably fans the cooler.

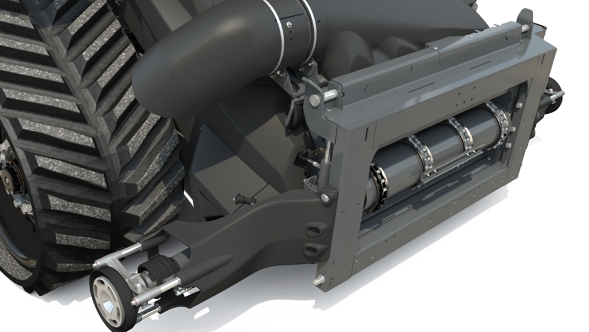

Fendt IDEAL Chassis

Slim mover

Maximum propulsion

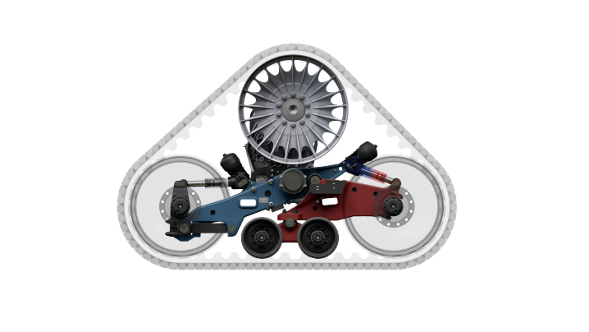

The transmission on the Fendt IDEAL

Fendt MotionShift

The Fendt IDEAL gearbox offers two gears with a speed range of 0-15 km/h or 0-40 km/h. Fendt MotionShift allows you to shift both gears conveniently during the ride using a button on the armrest. The speed can be easily controlled via the multi-function joystick. In CVT mode, the speed starts at 0 km/h. The IDEAL's acceleration is linked to the joystick position. Enable the unique Hookup mode on the armrest and the Fendt IDEAL reacts proportionally to joystick movements. This makes light work of coupling headers.

Workplace with the best view