“The end result is a range that delivers perfect results under any harvesting conditions,” comments Robbie Hall, Product Marketing Manager for Gold Harvesting, AGCO Africa. The Fendt IDEAL range is available in a wheeled, single or dual platform. PL is the designation for Para-level for extreme hillside harvesting while the T (track) is available in 30" and 36".

The four models are the Fendt IDEAL 7, 8, 9 and 10. The Fendt IDEAL 7 is a single-helix rotor, while 8, 9 and 10 are dual-helix rotors with different 3D wave pan designs. The internal working of the dual-helix rotor system provides the grain quality of a hybrid machine with the capacity and throughput of a rotary machine. The Fendt IDEAL 7 has an AGCO Power engine while the 8, 9 and 10 feature different MAN engines.

Launching in the South African market from April 2021, the Fendt IDEAL 10 will be the most advanced combine harvester available on the market, reports Mr Hall. Unveiled at Agritechnica 2019, this trend-setting machine does away with conventional steering wheel control and is instead equipped with the IDEALdrive steering system as optional on all track versions.

The Fendt IDEAL 10T has a new MAN 16.2-litre engine that meets Stage V European emissions standards and Tier 3A locally, it has a maximum output of 790 hp, which is 143 hp more than the second-largest Fendt IDEAL 9 model. The top model has a new cleaning system boasting 15% more cleaning capacity.

Thanks to the Cyclone Cleaning System, the grain drops down to the top sieve through two curved double-drop steps. The curved shape allows the heavy grains to gather in the lower section, while the lighter parts accumulate above. The curved steps provide a wider air outlet that can significantly increase the air volume for an even more efficient cleaning process.

With ideal two drop levels, most of the short straw and chaff is separated on the first level and the remaining non-grain components (MOG) on the second. Cleaning happens over four sections on the Fendt IDEAL 10T, and the two return floors are optimised by IDEALbalance to ensure even distribution and coverage across the preparation and sieve floor.

Dual Helix Rotor

The same Dual Helix Rotor as on the Fendt IDEAL 8 and 9 now comes with more separation area for the top-end model. Two additional separator concaves add 12% to the concave surface area. With a separation area of 4.54 m2, the combine harvester boasts an even higher separation capacity for greater throughput.

The new IDEALdrive steering system replaces the steering column altogether. It allows the machine to be controlled proportionately by moving a joystick on the left, with the same joystick functionality on the right armrest. The left armrest can be folded up for easy access to the driver’s seat. The steering system also provides the best view of the front wide header attachments, in addition to the perfect view, and road speeds of 40 km/h are standard with IdealDrive.

The Fendt IDEAL 7 and 8 have three feed chains in the crop elevator. Fitted with four feed chains, the output is even higher with the Fendt IDEAL 9 and 10. The front feeding drum is closed on all models. The chain tension and height can be adjusted easily by turning a shaft to switch the height between 50 mm and 98 mm to accommodate all crop types.

A key differentiator is the Single (Fendt IDEAL 7) or Dual Helix (Fendt IDEAL 8 to 10) processor that provides the highest output and best threshing quality with gentle crop handling and low energy consumption. The RotorFeeder feeding drum passes the crop from below to the rotors and its speed is set proportionally to the rotor, guaranteeing the best threshing results.

IDEALharvest sets a new benchmark in automated machine settings. Acoustic MAD sensors and smart algorithms to provide the data required to quickly and easily select from three key harvesting strategies. The rotor and fan speed, top and bottom sieve openings and forward speed are continually optimised to suit the selected strategy for throughput, grain quality and fuel consumption.

The machine's crop flow is also displayed in real-time, allowing the data to be used to assess crop distribution in the machine. Based on the real-time values of the installed sensors, the transfer volumes and grain losses are displayed onscreen. The Grain Quality Cam helps optimise the grain quality even further with real-time views on your iPad connected via in-cab Wi-Fi.

To ensure that nothing but clean crop lands in the grain tank, the unique and ingeniously simple IDEALbalance system consists of a double grain pan. The front grain pan collects the material threshed out by the rasp bars in the front part and forwards it to the front part of the preparation floor. The rear grain pan collects the material discarded from the rotor tines and sends it backwards to the preparation floor. This makes full use of the preparation floor and sieve, maximising the use of the sieve area.

The front grain pan is concave to gather the material in the middle of the pan. With a Dual Rotor, the rear grain pan is convex, so the crop collects at the outer ends. This distributes the crop in the machine properly in all conditions and up to a 15-degree side gradient, which is a straightforward design that avoids up to 60% losses compared to flat pans

The Fendt IDEAL 7 features a special grain pan option ideal for the single rotor. The powerful cyclone cleaning fan consists of three fan units with open sides for maximum air output. The fan speed can be hydraulically adjusted between 250 rpm and 1 400 rpm. The powerful airflow is split from the first drop stage, with a constant air flow generated over the entire length of the shaker shoe for best cleaning results.

The long preparation floors, high partitions and long shaker shoes provide for exceptional cleaning. Most short straw and chaff are separated from the grain on the first drop between preparation floor and intermediate floor. The second drop to the top sieve then separates the impurities further. A strong air flow ensures perfect cleaning results. The longest sieves on the market with the fitted partitions mean optimal grain purity. In order to deliver the best results under all conditions, the opening range of the sieves can be conveniently and easily electrically adjusted from the cab.

Every model comes with one of two straw chopper versions: The BaseCut with 56 knives across four rows or the ShortCut with 112 knives across eight rows as optional. Both choppers have maintenance-free bearings. The shear bar can be set to five positions without tools. The chaff spreader is placed directly at the end of the shaker shoe, distributing straw and chaff as desired. The distribution disks are hydraulically driven for variable speeds. The three straw distribution settings are chop and mix (chaff into chopper), drop straw and mix (chaff into swath) or separate the chaff from straw (chaff distributed sideways). The end of the straw chopper features either the ActiveSpread distributor and is all controlled from the cab.

Grain Tank

There are two grain tank versions, namely the Streamer 210 with a 17 100 litre capacity and a 210 litre/second unload rate or the Streamer 140 with a 12 500 litre capacity and 140 litres/second on all PL machines. The large 480 mm diameter with a few auger flights allows for simultaneous low speeds. The grain tank is fully unloaded within 81 seconds. The discharge rate can be hydraulically adjusted from the cab. The grain tank lift is designed for a throughput of up to 200 t/h. The elevator housing measures 239 mm in diameter, leaving enough space for high throughput in all crop types. A total of 40 convex paddles ensure maximum performance with gentle crop handling.

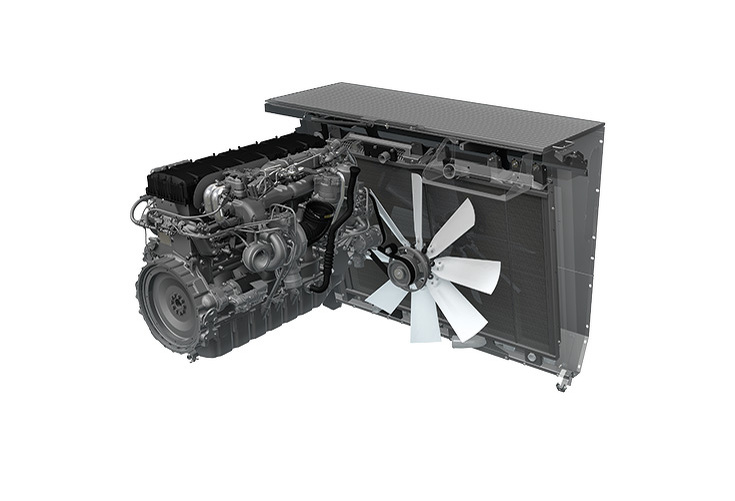

Revolutionary AirSense® Cooling

AirSense Cooling provides maximum cooling capacity with minimal cleaning effort. It consists of a 950 mm reversible fan and a cooling area of 2.7 m². The air is extracted centrally through a radiator grille on the top side. Depending on the temperature and time, the fan automatically changes its direction of rotation and reliably fans the cooler. Dirt and dust never impair the cooling performance as the reverse van is self-cleaning.

There is an air compressor to clean the machine on a daily basis, driven directly by the engine. The maximum pressure is 9.5 bar with a capacity of 60 litres. Two air connections, one on the cab steps and one on the access ladder to the engine platform, allow for an air hose to be connected for easy machine cleaning in the field.

The diesel tank (1 500 litres) and AdBlue tank (180 litres) are located at the rear for optimal weight distribution. Combined with the low fuel consumption, this means the machine can be operated for extremely long periods.

Tried-and-tested gearbox technology is combined with the latest hydrostatic ground drive technology. The brake and differential lock are held directly in the transmission housing. Every model has a differential lock as standard. The gearbox offers two ranges with a speed range of 0-15 km/h or 0-40 km/h in road mode.

MotionShift allows for both ranges to be shifted conveniently during the ride by means of a button on the armrest. The speed can be easily controlled via the multi-function joystick. A number of ride strategies are available in order to enhance efficiency and comfort when on the roads.

In advanced mode, the engine speed follows the required forward speed and reduces the speed for maximum efficiency by up to 300 rpm, depending on load. In time mode, the engine speed follows the default. The DriveCentre completely redefines the drive concept, with all pumps such as load-sensing hydraulics or the drive pump now directly driven for no performance loss.

VisionCab

The Fendt VisionCab is the perfect workplace with the best view over the attachment due to a window area of 5.75 m² and a 180° panoramic view, while the low noise level of just 73 db creates a pleasant working atmosphere. The generous driver’s cab means even long-legged drivers can enjoy a comfortable seat with deluxe leather and active ventilation.

Ultimate Comfort

At the heart of the combine harvester’s simple and intuitive operation is the armrest, featuring a handy joystick and a membrane/toggle button for machine functions. There is also a small digital display for key machine settings. The Varioterminal 10.4" also allows for easy adjustment of the machine by tapping or pressing a button. For advanced machine functions such as IDEALharvest, an iPad can simply be clicked into the stable and practical holder in order to run the application.

“This is an exciting, completely new design from any conventional combine. It reflects the exceptional quality and innovation based on the latest trends and technologies,” concludes Mr Hall. The Fendt IDEAL range has been developed in line with AGCO Africa’s commitment to rapid innovation and evolution of precision agriculture solutions to help farmers produce more with less environmental impact.