The DLG attended the test as an independent institution and recorded the results impartially. The highly qualified expert engineers from the DLG Test Centre in Groß Umstadt have been carrying out threshing tests for many decades. As an external expert, Prof. Thomas Rademacher, Professor of Agricultural Engineering at Bingen University, supported the DLG to validate and control various measurement techniques during the tests.

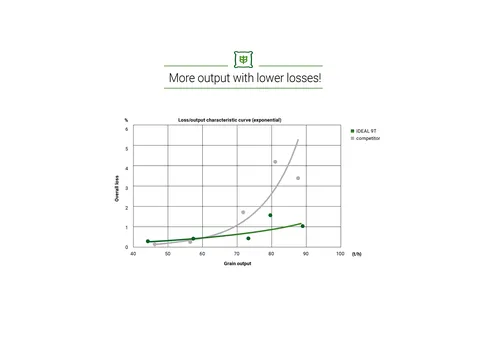

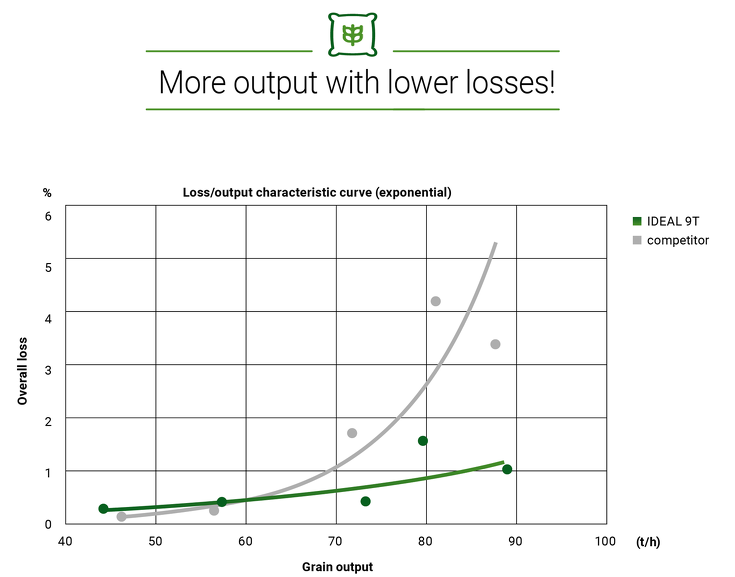

"The aim of this project is to put together a characteristic curve for output loss from a variety of combine harvesters," says Prof. Rademacher. "The machines drive in the field at different output rates or driving speeds, while we measure the grain losses."

High output at low losses

The DLG test was carried out in a wheat field in five measurements between 4 and 8 km/h. At a top speed of 8 km/h, the Fendt IDEAL 9T reached an output rate of 89 tonnes per hour. The comparison machine recorded a lower rate of 87.7 tonnes per hour of grain output, at significantly higher levels of grain loss. At a standard grain loss level of 1%, the Fendt large combine achieved a 21.6% higher grain output compared to its competitor.

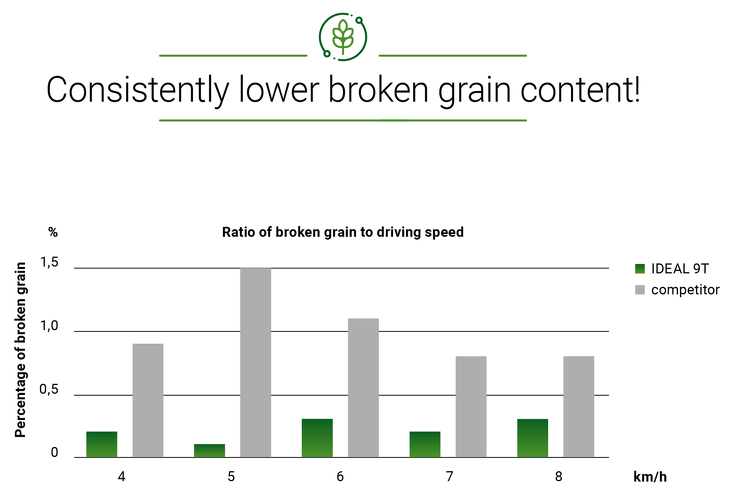

Negligible broken grain content from the Fendt IDEAL

The amount of broken grain is also decisive for the quality of the crop. In this aspect, the Fendt IDEAL came out top, with its results registering in the 'very low' range. The broken grain content was 0.15% to 0.55%, while the comparison machine recorded 0.85% to 1.5%; significantly exceeding the readings from the Fendt machine.

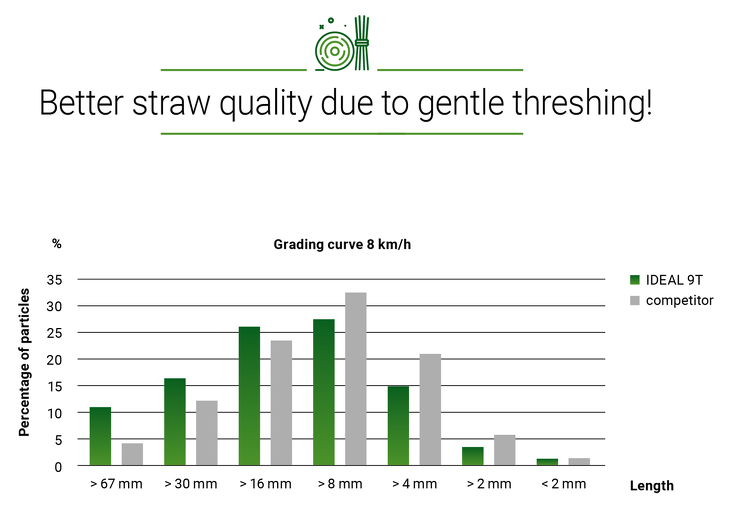

High proportion of long straw

The straw quality of the Fendt IDEAL was particularly evident in the long straw range. When measured at 8 km/h, 10% of the straw sampled was long straw measuring more than 67 mm in length; 17% of the straw sampled measured longer than 30 mm. That is 2.7x more long straw than the samples taken from the comparison machine. The short straw content in particular was in the range of 8 mm, which was significantly higher than in the Fendt IDEAL.

About the combine harvester comparison test

The test pitted the Fendt IDEAL 9T against a combine harvester of the same performance class and the same cutting unit width, both harvesting in wheat on a field in Mecklenburg-Western Pomerania.

"Following measurement method standards, we used the 'sheet procedure'. This means that all deposits from the combine harvester are placed on a sheet and then cleared again to identify and weigh the grain losses. We used the well-known shell method alongside that, as an additional control method," says Prof. Rademacher.

Both machines were calibrated before the test and each was set up by technicians from the combine manufacturer to undergo extensive tests under the same conditions. The output and losses were tested using two assessment methods in five test rows and at different speeds between 4 and 8 km/h.

"The assessment is based on the principle that everything that goes into a machine has to be weighed," says Prof. Rademacher. "Both combine harvesters unloaded the grain onto a weighing cart after each partial inspection. We use this and the pre-set driving speed to determine the grain output."

The samples taken were then examined and assessed by independent experts in the DLG lab. The losses are evaluated by looking at the straw and the chaff. The clean grain losses are weighed as well as the straw and chaff. On the basis of the yield, the grain losses can then also be calculated.

"For the first time in Fendt history, we have subjected a combine harvester to an independent DLG comparison test to show the public how well we fare among the best," said Christoph Gröblinghoff, Chairman of Fendt Management Board, commenting on the heavyweight test. "The Fendt IDEAL combine harvester meets all our expectations in these extensive test runs. But even more importantly, it also meets the expectations that customers place on a Fendt combine harvester with innovative technology and such high performance data."