The loader wagon comparison test was accompanied and documented by DLG TestService GmbH as an independent institution. Both the Fendt Tigo 90 XR D and the competitor loader wagon were used in tandem with the same Fendt 942 Vario on a grassland area in Saxony-Anhalt in second cut grass. During the comparison, tests were carried out with multiple repetitions in the different speed ranges and at the maximum working speed of the respective wagon.

High throughput with low power requirements

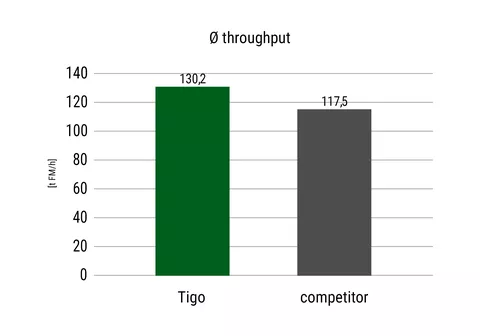

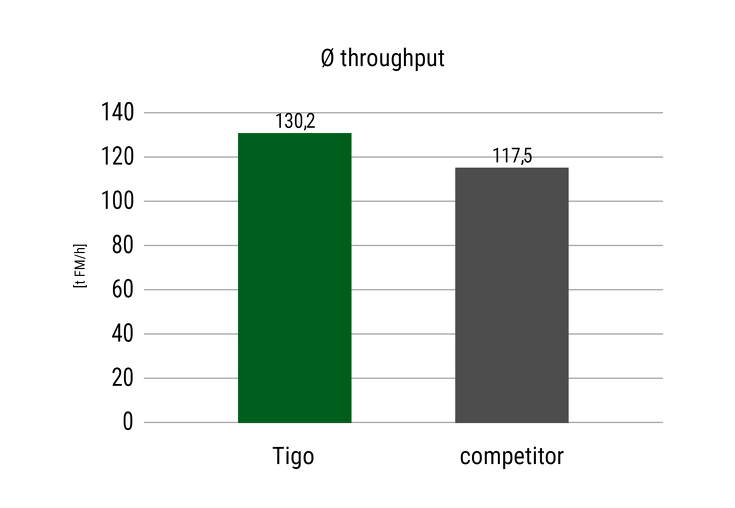

To find the average recovery rate of each loader wagon, the average of the test runs for both machines were calculated. An average recovery rate of 130.2 tonnes of fresh matter (FM) per hour (t FM/h) was determined for the Fendt Tigo, while the recovery rate of the competitor machine was 117.5 t FM/h on average.

In the comparison test performed, the throughput of the Fendt Tigo 90 XR at maximum working speed was 10.8 percent higher than the comparable competitor machine. In addition, the Fendt Tigo compacts the forage mass six percent more than the comparison model.

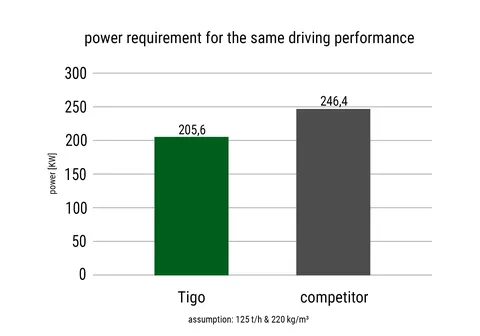

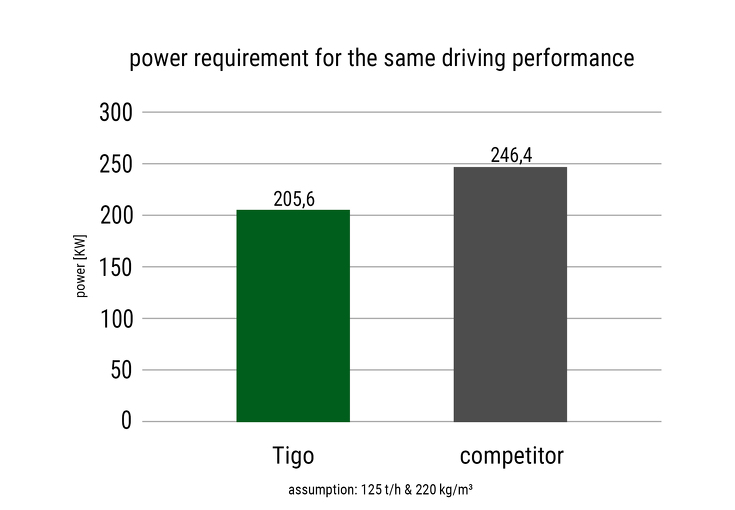

In order to determine the power requirement, the average power requirement at maximum forward speed was first determined. The compaction power and the throughput of the loader wagons were then standardised and the theoretical power requirement calculated. For this purpose, 220 kg/m³ was assumed for the compaction capacity of both loader wagons and 125 t/h for the throughput. To achieve these outputs, the Fendt Tigo in the test needed a theoretical power requirement of 206 kW and the competitor model 246 kW. This means that the theoretical power requirement at the PTO of the Fendt Tigo at standardised power under the test conditions was 16.6 percent lower than that of the comparison machine.

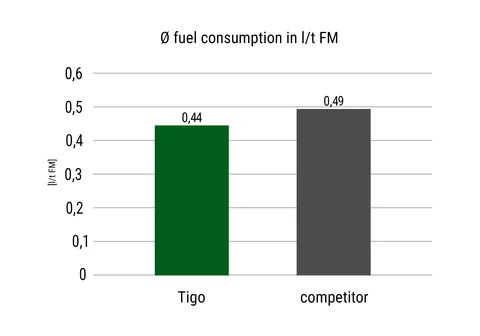

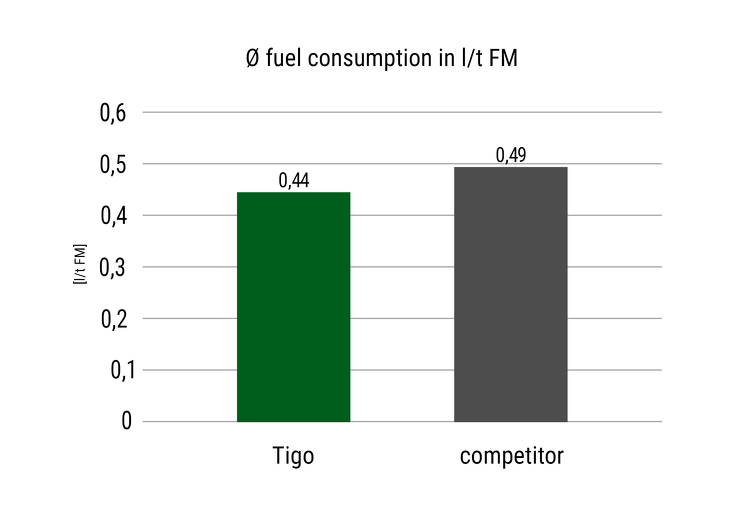

10.4 percent less fuel

At maximum working speed, the Fendt 942 Vario with the Fendt Tigo required 0.44 litres per loaded tonne of fresh matter in the test, while the same tractor with the competitor machine required 0.49 l/t of fresh matter. This corresponds to a 10.4 percent higher fuel consumption per tonne of fresh matter compared to the Fendt Tigo. The decisive factor for the low fuel consumption of the Fendt loader wagon is the combination of a lower power requirement and a higher throughput.

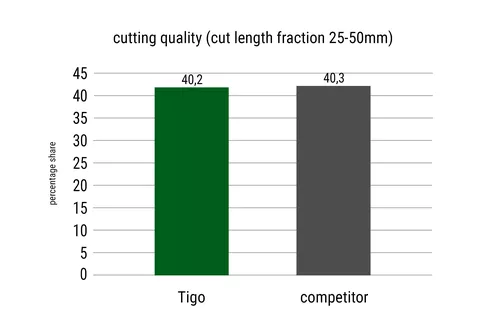

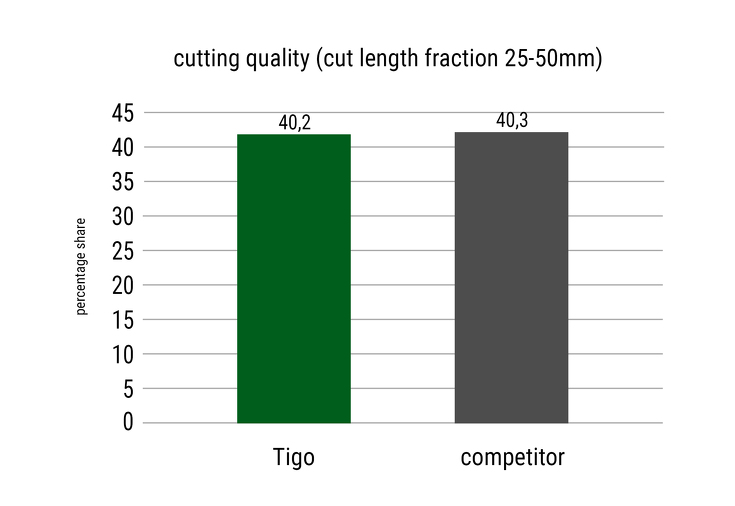

Excellent cutting quality

At maximum working speed, the chop quality values were also recorded. A cutting length of 25-50 mm was specified as the target range for the test. With a portion of 40.2 percent of the cut lengths in this target range, the Fendt Tigo was convincing with its excellent chop quality.

The values for pick-up loss and soil contamination were determined at a working speed of 15 km/h. The pick-up losses for the Fendt Tigo 90 XR were 0.3 percent and thus achieved the top mark of "Very low (++)" according to the DLG evaluation scheme. With 0.9 percent intake losses, the comparison model achieved the rating "Low (+)" according to the DLG evaluation scheme. In the evaluation of the soil contamination, a crude ash content of up to nine percent is considered the limit value for clean fodder. In all samples, the crude ash content was clearly below the limit value and is accordingly rated as excellent.

"The Fendt Tigo 90 XR is a loader wagon for professional farmers and contractors. Key figures such as throughput and daily output are becoming increasingly decisive with narrow harvesting windows. The test results show that the machine delivers the best daily output at maximum speed and is fuel-efficient," sums up Roland Schmidt, Vice President Marketing Fendt. "The outstanding values for intake loss as well as feed contamination are an important key figure especially for dairy farms."

DLG recognition procedure

With the test results from the comparative test, a DLG recognition procedure was also sought for the Fendt Tigo 90 XR to be awarded the DLG test mark DLG ANERKANNT [RECOGNISED] in the DLG test module "Function and quality of work". The resulting DLG test report will be published shortly.

Test conditions during the loader wagon comparison

Temperatures during the comparative test were between 22.6° and 28.1°C, with humidity between 29.5 and 59.4 per cent. The amount of rainfall on the trial plot was low compared to previous years.

Due to the high dry matter content, the areas were mown one hour before the trial and then raked with a Fendt Former 14055. The tractor pulling the rake was equipped with a track guidance system to create as even a swath as possible. The swath spacing was between 18 and 24 metres.