Whether its a single, two or four-rotor hay rake: All Fendt Formers are designed to make it easy, to form your quality forage. Smart details like flexHigh, CamControl, SteerGuard or the Jet-Effect help you to keep the shape of your forage even on headlands, and the sturdy design ensures a long lifetime.

Tidy work. The Fendt Former Hay Rake.

Do you expect nothing but the highest quality forage in your swath? Then you should definitely take a look at the innovative Fendt Former hay rakes. With an operating width of up to 13.8 m, they are experts in adding quality forage cleanly and precisely to the swath, anytime and under all conditions.

The best of all worlds. Innovative technology for cleaner forage.

Every last stalk matters during the forage harvest.

All Fendt Former multi-rotor hay rakes have a fully cardanic rotor suspension. This gives them outstanding adjustability to the ground, both lengthwise and diagonally, with even forage which lies in wheel tracks or hollows being harvestable without being lost. As a result, the sward is also protected on uneven terrain.

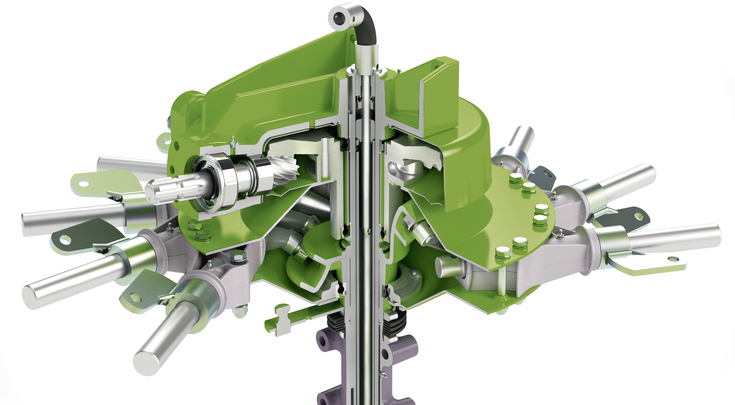

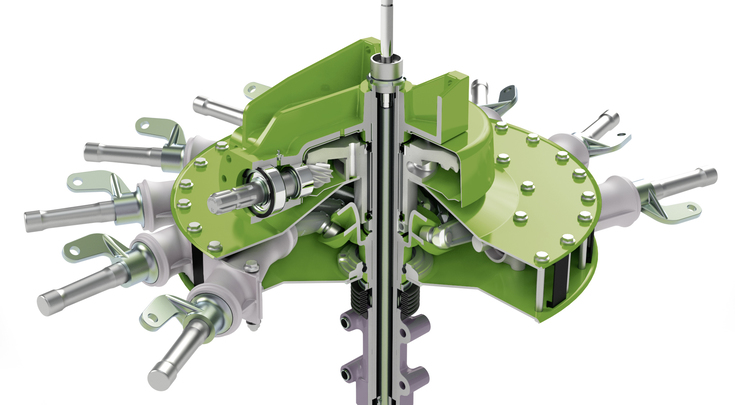

Hay rake heads for maximum durability

Various rake heads are fitted according to the model. All are designed for stability and longevity. The maintenance-friendly Former 3 and Former 4 rake heads are bolted using taper rings to form a single sturdy unit, leading to perfect centring. The screws are not exposed to shear forces. The Former 5 and Former 6 hay rake heads are fitted with a maintenance-free rotor arm bearing. Ball bearings with large distances between are used. These provide the head with the ultimate in stability.

Efficient deposit

The tine arms of the Fendt Former rakes are arranged at tangents. This provides the ultimate in raking quality and optimal forage pick-up even at higher speeds. As the double tines are screwed into the tine holders from below a smooth surface on which no forage can hook is produced. The clearance of the tines to the coils is also completed unlimited. The tine arms can be detached after removing a single cotter pin, and tine arm control shafts can be replaced individually without disassembling the rake flange. To do this, only individual screws need to be loosened.

Precision ground following

Simple but low-wear, durable and above all, precise: this is the patented SteerGuard steering system. The stub axle steering uses adjustable track rod heads from the commercial vehicle sector. This ensures precise self-steering and excellent stability. In order to direct steering forces towards the rear, the steering shaft is located within the frame and protected against damage. It has just a few separation points and mounts and is therefore very low wear.

Perfectly formed swath

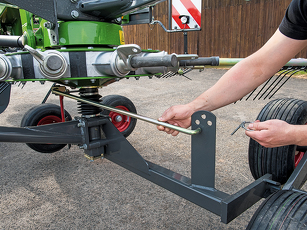

The best swath is the result of an optimised cam track. The special design of the Fendt Former cam track ensures that the tines are lifted and lowered precisely. Due to the standard cam track adjustment, the delivery time can be individually adjusted depending on the forage quality, so that the swath is perfectly formed under all conditions. The output of the trailed machines therefore increases appreciably. The closed design protects the cam track against dirt and dust, and the rotors are very smooth running thanks to the permanent lubrication.

Whether the forage is long and heavy, or short and light: The cam track can be easily adjusted to suit the harvesting conditions using a hole template.

Optimum soil protection and clean forage.

Perfectly adaptable

The fully cardanic suspension of the rotors ensures a continuous and frame-independent adjustment to the ground contour in longitudinal and transverse inclination. This allows the crop to be recovered without loss, even in ridged terrain with reduced raw ash content.

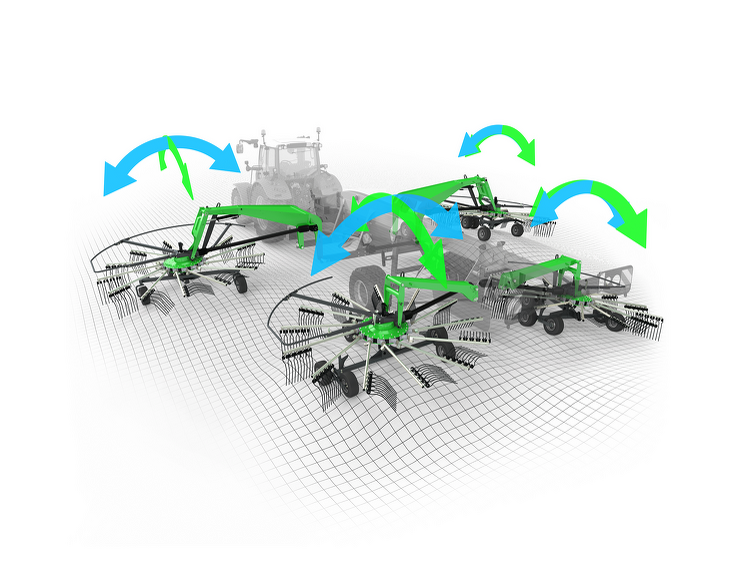

Perfectly lifted

The rotors’ pivot outside the centre of gravity ensures that they lift first at the front and then at the back - the jet-effect. The process runs in reverse when lowering: The rotor touches the ground first at the back and then at the front, which stops the tines from penetrating the ground. Tines as well as the sward are therefore protected and the forage is kept free of dirt and contaminants.

Optimal forage quality thanks to Jet-Effect

The rotors’ pivot outside the centre of gravity ensures that they lift first at the front and then at the back. The process runs in reverse when lowering: The rotor touches the ground first at the back and then at the front, which stops the tines from penetrating the ground. Tines as well as the sward are therefore protected and the forage is kept free of dirt and contaminants.

Perfect rotor chassis

The Fendt Former hay rake wide-track chassis ensures optimal ground following, also on uneven and steep terrain. Additional smooth running and stability enables tandem axle configurations. The Fendt Former allows you to work efficiently and cleanly in any conditions and forage types. For optimal raking, the rotor chassis can be tilted lengthwise and horizontally.

Experience in Hay

A century of silage expertise Tradition, innovation and passion – that’s the recipe for success of the silage centre of expertise in Feucht.