Global challenges: innovation is key

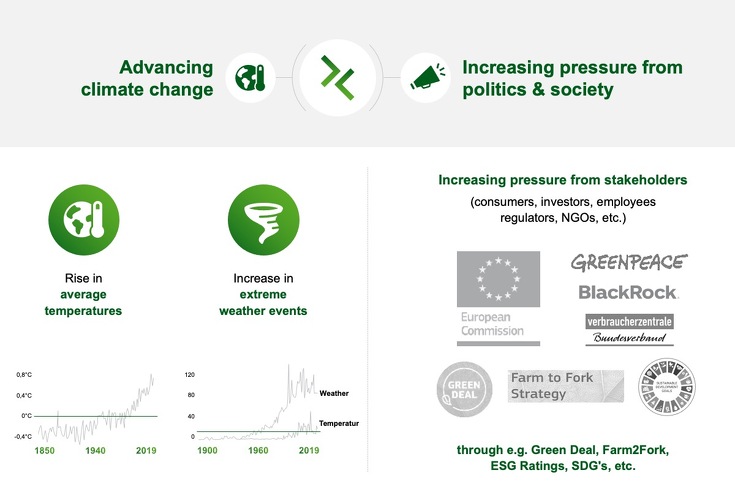

The world is facing great challenges – and agriculture is playing a central role. In 2050, around ten billion people will be living on our planet. Against the background of the ongoing effects of climate change, innovative technical solutions are required in order to be able to feed the world population and simultaneously use existing resources as efficiently as possible. With rising demand for agricultural products, the efficiency and durability of the machinery used is key to raising food production in an environmentally sound way whilst, at the same time, using as few resources as possible.