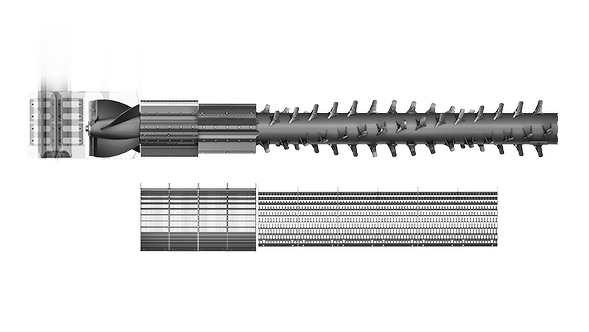

Single Helix

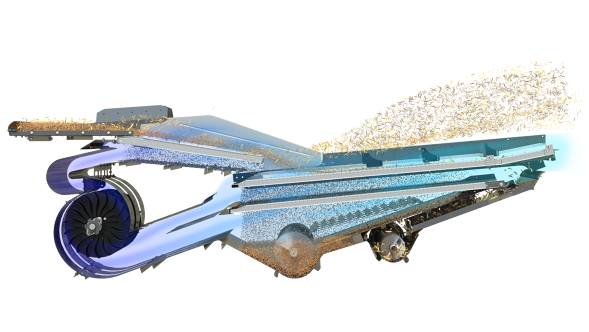

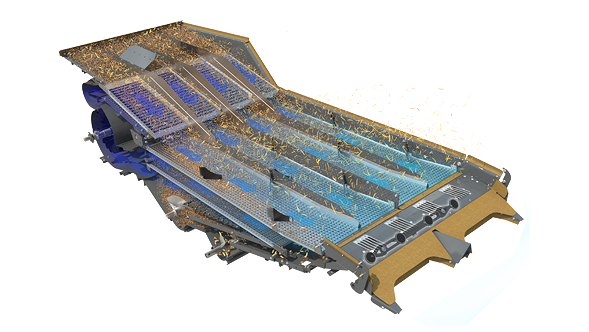

The IDEAL 7 is equipped with one rotor, the so-called Single Helix. With the Single Helix processor, the IDEAL 7 has a threshing concave area of 1287 sq/inches and a separation area of 2232 sq/inches.

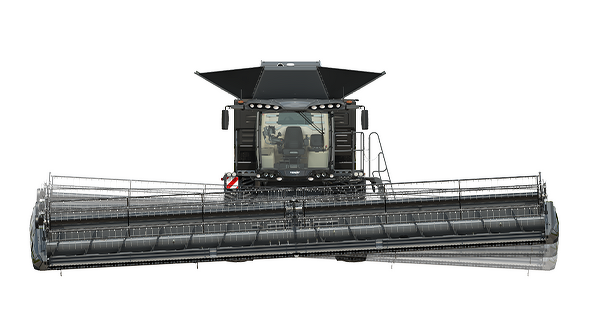

The Fendt IDEAL was developed in the global AGCO Centers of Excellence for harvesting technology. Countless farmers and contractors from around the world were asked what combine requirements would make their IDEAL harvest. It's the culmination of this customer input, the combined experience of our developers and the chance to test the Fendt IDEAL all year round in different regions under the harshest operating conditions, that make the Fendt IDEAL the most modern and innovative combine on the market.

| IDEAL 7 | 355 kw | 476 hp |

| IDEAL 8 | 404 kw | 541 hp |

| IDEAL 9 | 485 kw | 650 hp |

| IDEAL 10 | 581 kw | 779 hp |

Immerse yourself in moving stories from our project "Your IDEAL story". Customers from around the world are sharing their IDEAL experiences and how the IDEAL combine has revolutionized their harvest. Together with them and our experts, we exchanged ideas and collected valuable feedback to make the IDEAL combine even more powerful.

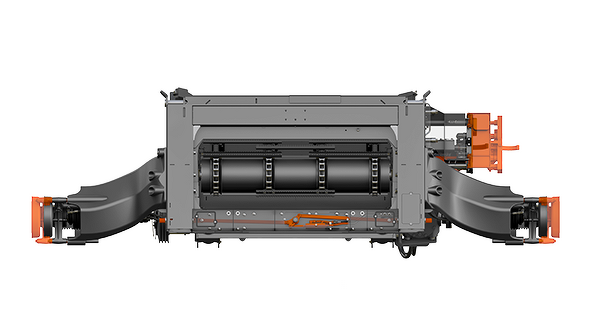

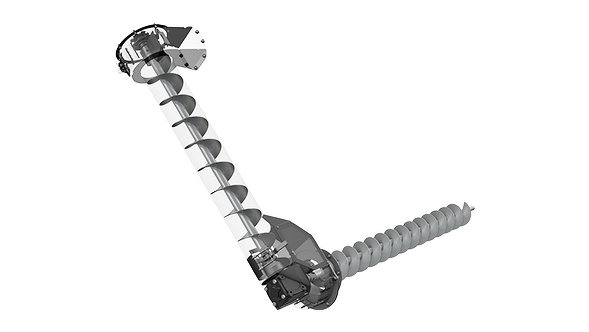

Short setup times mean more time for harvesting. Fendt Autodock™ automatically couples the attachment within 5 seconds, setting standards in terms of ease of use. You don't even have to leave the driver's seat. Once the attachment is added, 4 hydraulic cylinders complete the connection. A hydraulic cylinder in the middle of the crop elevator frame mechanically locks the attachment. At the same time, two couplings push out to connect the PTO drives. Autodock™ connects the multi-coupler separately to the attachment and the machine. Equipping your combine with Autodock translates into significant time savings—and as we know, time is money. Consider the scenario of harvesting 40 fields: this equates to at least 80 connections annually. With Autodock, you’re saving approximately 10 minutes per connection. In a year, that adds up to a reduction of nearly one full week in your harvesting schedule, streamlining your operations and boosting efficiency.

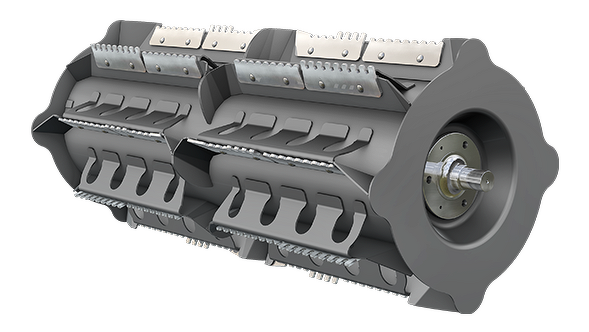

All components of the rotors such as the rasp bars and rotor tines are arranged in four rows like a helix. The front part of the rotors consists of 4 rasp bars installed lengthways which loosen the grains from the ears. The concaves below are available in different designs for the best results in any application. They can be replaced quickly and easily from the side, depending on the application. The gaps between concaves are hydraulically adjusted up to a maximum of 1 3/8 inches. The rotor tines are tilted 20° to the rear, which divides the crop into the helix sections and reliably and gently runs it around the rotor. This prevents unexpected load peaks on the rotor and there are no edges for the product to stick to.

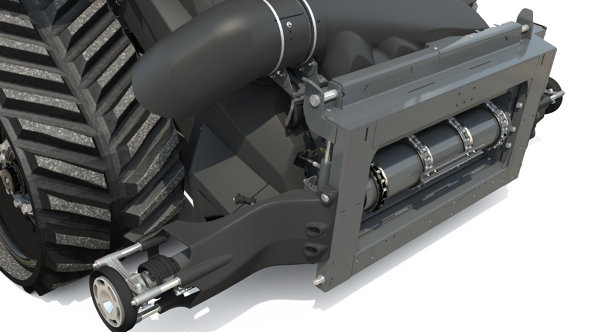

The RotorFeeder feeding drum with 23 5/8 inches passes the crop from below to the rotors, guaranteeing the best threshing results. The RotorFeeder speed is automatically controlled in proportion to the rotor speed – always at 70% of the rotor speed. Because the speed is adjusted to best match the rotor speed and the large transfer area, the straw is kept intact. The RotorFeeder also uses far less power during this process. A constant flow of crop is guaranteed by the optimal transfer.

The height of each rotor tine is 5 1/2 inches. Perfectly separated grain without damaging the product too much in too confined a space. In turn you get high straw quality and best threshing at low power. The threshing system is also distinguished by its simple configuration. The operator only needs to change the rotor speed range and the concave clearance.

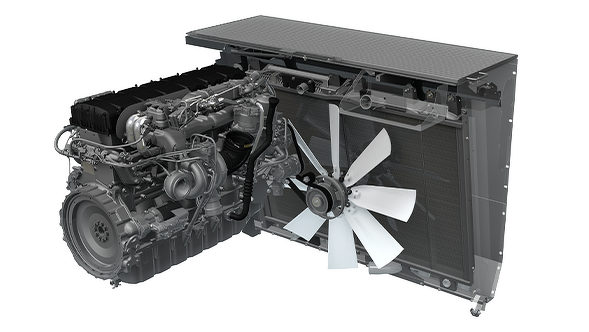

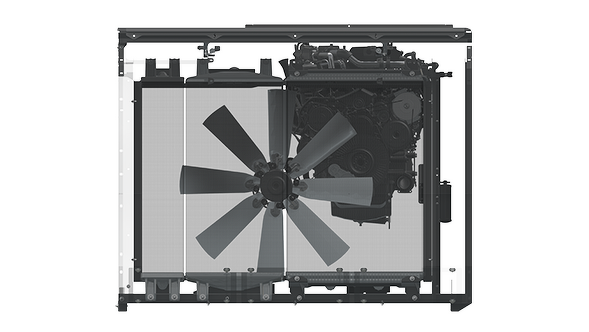

To give you the best overall package, the 4 different Fendt IDEAL models also work with 4 different engines, which are perfectly adapted to the potential output of the IDEAL 7, 8, 9 and 10. Maximum fuel efficiency can only be achieved with an engine that is perfectly matched to the machine. The IDEAL 7 is powered by a 9.8-liter AGCOPower engine producing 476 hp and the IDEAL 8, 9 and 10 models use three different MAN engines. All engines comply with emissions Tier 4F regulations and are noted for their long service intervals.

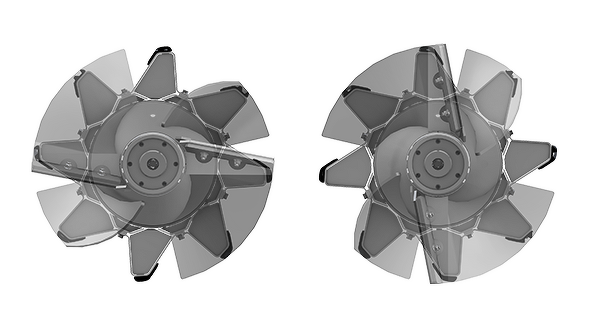

Cooling is a crucial part of ensuring the engines always run efficiently and reliably. AirSense® Cooling was developed for the Fendt IDEAL. The idea is to provide maximum cooling capacity with minimal cleaning effort. AirSense® Cooling consists of a 37.4 inches reversible fan and a cooling area of 4185 sq/in. The air is extracted centrally through a radiator grill on the top side of the Fendt IDEAL. Depending on the temperature and time, the fan automatically changes its direction of rotation and reliably fans the cooler.

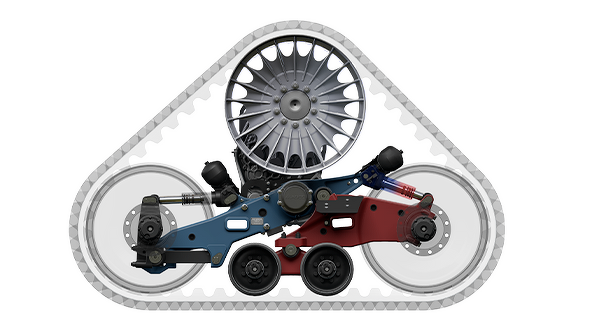

The IDEAL automatically switches to 4WD mode independently and intelligently only when the adjusted pressure of the front axle is reached. This means that the AllDrive axis supports the IDEAL only where necessary to deliver full traction, With the differential lock on, the AWD is permanently on. When you steer the differential lock turns off, and after the maneuver comes back on again. With this, the IDEAL saves on fuel and protects the axle.

The Fendt IDEAL gearbox offers two gears with a speed range of 9.3 mph km/h or 0-25 mph. Fendt MotionShift allows you to shift both gear conveniently during the ride using a button on the armrest. The speed can be easily controlled via the multi-function joystick. In CVT mode, the speed starts at 0 mph. The IDEAL's acceleration is linked to the joystick position. Enable the unique Hookup mode on the armrest and the Fendt IDEAL reacts proportionally to joystick movements. This makes light work of coupling attachments.

The Fendt VisionCab was designed to offer you the perfect workplace with the best view over the attachment. It does this with a window area of 6.19 sq/ft and a 180° panoramic view. The low noise level of just 73 db creates a pleasant working atmosphere. The generous driver's cab means even long-legged drivers can enjoy a comfortable seat.