Fendt Momentum Crop Tour

2020 was a year of unprecedented challenges, but it didn’t stop the AGCO Crop Care team from delivering on its promise to offer helpful information and agronomic solutions to growers. At Fendt Momentum Crop Tour locations across the Corn Belt, the team asked new questions about the effects of soil compaction created by central-fill planters and demonstrated best planting practices. The results reveal ways growers can lessen the yield impact of wheel traffic and pinch-row compaction and maximize yields by planting seed with proper depth, downforce and spacing. Learn more below:

For more information about best planting practices and observations from the AGCO Crop Tour, watch the 2020 Fendt Momentum Virtual Crop Tour below or on YouTube at https://youtu.be/Viqxt06_NMw. Contact your local dealer to learn more about the Fendt Momentum planter.

AGCO Crop Tour Harvest Report No. 1: Planter Compaction Yield Penalties

Observations indicate soil compaction from wheel traffic and pinch rows can be managed.

During the 2020 growing season, the AGCO agronomy team planted field demonstration plots were in five locations in the United States, including Illinois, Minnesota, Ohio, North Dakota and South Dakota. In addition to continued comparisons of the impacts of various planting depths, downforce levels and seed singulation on corn yield, the AGCO team also measured the effect of equipment-induced soil compaction on the crop in 2020.

“Soil compaction caused by wheel traffic is an increasing concern among farmers, especially due to the weight of today’s tractors and high-capacity, central-fill planters,” says Jason Lee, AGCO agronomist and farm solutions specialist. “Compaction can restrict root growth, limit nutrient and water uptake and ultimately lower corn yield. Our plots in 2020 looked at ways growers can reduce compaction at planting and avoid those yield penalties.”

The AGCO team asked three questions regarding planter-induced soil compaction:

1. Is there yield loss in the center rows planted with high-capacity, central-fill planters?

2. Can yield loss be mitigated when planting with high-capacity, central-fill planters?

3. Does pinch-row soil compaction cause yield loss, and if so, how much?

At all five locations, corn was planted with a Fendt Momentum planter pulled by a row-crop tractor running dual tires. All comparisons were planted in 30-inch rows, with the exception of the North Dakota location where the corn was planted in 22-inch rows.

To compare the impact of compaction caused by tire pressure and planter weight, the plots were planted using one of three settings on the Momentum planter:

· Load balance. The planter’s optional Load Logic system automatically monitored and hydraulically transferred weight equally to all wheels, while also automatically adjusting tire pressure to the lowest manufacturer-recommended psi for the weight.

· Controlled traffic. The system intentionally pulled weight from the wings and concentrated it on the in-line tandem transport wheels, also with auto-adjusted low tire pressure.

· Disabled. The Load Logic system was disabled so the planter operated much like other central-fill planters, with the weight concentrated in the middle of the planter and tire inflation pressures at a static 55 psi, a common road-transport pressure level.

To allow for yield comparisons, rows from wing sections of the planter were harvested separately from the center section at four of the locations. At the Ohio location, each row was harvested individually to determine its yield.

Takeaway No. 1: Eliminating pinch rows likely to improve yields

Of all the yield data, none was more telling than the row-by-row comparison made at the Ohio location where Lee described the soil condition at planting as “a little tacky.” This led to some soil compaction, which restricted root growth and impacted the corn crop later in the season when the weather turned dry.

Rows were designated as pinch rows (those with a tire track on both sides of the row), affected rows (those with a tire track on one side of the row) and non-affected rows (no tire tracks). The resulting agronomic message was clear: Pinch-row soil compaction reduces yield, especially in less-than-ideal planting conditions.

“Because of its in-line tandem wheel design, Momentum creates no pinch rows like other planters where there are tire tracks on both side of a row,” Lee explains. “The dual wheels on our row-crop tractor created two pinch rows, and those rows averaged about 194 bushels per acre, whereas the rows without wheel compaction averaged a little more than 203 bushels per acre.”

The two pinch rows created by the tractor yielded 9 bushels less than the rest of the rows across the planter. When that loss is averaged across the entire planter, the total yield penalty from pinch rows was 2 bushels per acre in this comparison.

“While it’s only one year of data at one location, our results mirror the same yield penalty that others have demonstrated. The more pinch rows in your setup, the larger the potential impact on overall yield in a field. That being said, how many pinch rows are you creating at planting?” asks Lee.

Lee notes it was interesting that the plot showed virtually no yield difference between rows affected by compaction on only one side and rows without compaction.

“I would have expected some yield loss. We’ll repeat these demonstrations in other soil types with varying planting conditions and tillage practices to see if the trend continues,” he adds.

Takeaway No. 2: Planting into ideal soil conditions is best

Lee says that at three of the five locations, there was no yield difference on average between wing sections and the center planter section, regardless of the combination of air pressure in the tires and how the planter weight was managed.

“We recorded an average yield difference of less than 1 bushel per acre, so you have to ask why,” Lee says. “And the answer is simple: When we planted at those three locations, the conditions were ideal. The soil moisture was incredibly fit for planting, to the point we weren’t going to create enough compaction to produce yield differences. I think it really emphasizes the importance of planting into fit conditions.”

Takeaway No. 3: Yield loss from center-fill planter compaction can be mitigated

At the North Dakota location, wet soil conditions at planting led to soil compaction, providing a different yield result. With Momentum’s weight-transfer system enabled and spreading weight across the entire planter, rows from the planter’s center section averaged 8 bushels more per acre than when the system was disabled and weight was concentrated in the center rows.

“Yes, we want to plant into fit conditions, but oftentimes, Mother Nature doesn’t cooperate,” Lee says. “That’s what happened in North Dakota. Our location was super-flat and poorly drained. Planting into that wet soil made it quite evident that by spreading the weight of the planter across the entire machine, we can mitigate compaction-induced yield loss from high-capacity, central-fill planters, especially in the center section where the planter weight is typically concentrated.”

Growers often select high-capacity, central-fill planters to increase productivity and maximize the acres they plant during the short planting windows that provide optimum yields. However, the planter’s weight may have negative agronomic consequences leading to yield loss. The 2020 Crop Tour confirmed this conundrum but offers a solution in the form of Fendt’s innovative planter design.

“With Momentum, we don’t have to sacrifice the agronomics to be productive,” Lee says. “I’m looking forward to the 2021 Crop Tour and learning more about how we can help growers improve their planting practices and ensure their corn crop reaches its full yield potential.”

AGCO Crop Tour Harvest Report No. 2: Prioritize Seed Placement

Maximizing corn yields begins by planting seed with proper depth, downforce and spacing.

During the 2020 growing season, field demonstration plots were planted in five locations in the United States, including Illinois, Minnesota, Ohio, North Dakota and South Dakota. In addition to evaluating the effect of equipment-induced soil compaction at all locations, the AGCO team continued its comparisons of various planting depths, downforce levels and seed singulation on corn yield at the South Dakota, Minnesota and Ohio locations.

“During the past five years, we have conducted more than 50 field comparisons in North America and around the globe demonstrating the importance of proper corn seed placement,” says Jason Lee, AGCO agronomist and farm solutions specialist. “What we’ve shown is that there’s no substitute for getting seed planted into adequate soil moisture at a depth sufficient enough to allow for uniform emergence and good nodal root development.”

The AGCO team compared corn plant performance and yield based on three variables:

1. Depth – Corn was planted at six depths ranging from 1 inch to 3.5 inches.

2. Downforce – Corn was planted with light downforce, heavy downforce and real-time

automatic downforce control provided by DeltaForce automated downforce from Precision Planting.

3. Spacing – Corn was planted at two singulation rates – 93 percent and 99 percent seed

spacing accuracy.

Corn was planted with a Fendt Momentum planter pulled by a row-crop tractor running dual tires. All comparisons were planted in 30-inch rows, with the exception of the North Dakota location, where the corn was planted in 22-inch rows.

Takeaway No. 1: Plant into moisture and no less than 1.5 inches deep

Crop Tour comparisons verify there can be yield penalties when corn is planted too shallow or too deep. Plant too shallow (1 inch deep or less), and the corn plant’s nodal roots will develop at or just below the soil surface. Limited nodal root development is detrimental especially when conditions turn hot and dry. Lee says this was especially evident at the Ohio location where soil was wet at planting, then dry during the growing season. Corn planted 1 inch deep exhibited more tip-back on the ears than corn in rows planted at 1.5 inches or deeper, due to the combination of poor nodal root development and dry growing conditions.

“When we get tip-back, there is little or no kernel development on the last one or more inches of the ear tip. That’s lost yield potential,” Lee says. “Over the past five years, we found that corn planted 1.5 inches deep yielded 13 more bushels per acre on average than corn planted 1 inch deep. At current corn prices, we’re talking about $50 or more in lost return per acre due to planting too shallow.”

In certain conditions, planting too deep can reduce the total number of plants that emerge and cause uneven emergence. Reduced emergence lowers the overall plant population; uneven emergence leads to runt plants that can’t compete with their neighbors for resources. Both reduce yield potential. At the Ohio location, corn planted 3 inches deep yielded 6 bushels per acre more in 2020 than corn planted 3.5 inches deep — a difference that closely mirrors the five-year average.

“Typically, a planting depth of 2 inches will provide the maximum yield potential in most planting conditions. This can vary, however, and adjustments should be made based on soil moisture and the extended weather forecast,” Lee says. “We know that planting depth is a simple adjustment to set, but it’s such a critical piece to maximizing corn yield.”

Takeaway No. 2: Don’t skimp on downforce

Once proper planting depth is determined, it’s crucial that enough downforce is placed on each row unit to maintain that depth. Inconsistent depth control also can lead to uneven corn emergence, resulting in yield loss.

“Soil type and condition changes across a field, and growers have different options for maintaining corn seed depth, including spring, air bag and hydraulic downforce systems,” Lee says. “As with planting depth, downforce is a balance. Set it too light, and the seed doesn’t get placed to the right depth because there’s simply not enough force to keep it there. However, too much downforce can create sidewall compaction in the seed trench, which can lead to root development issues.”

During the past five years, AGCO Crop Tour trials have compared three downforce protocols: light downforce, heavy downforce and automatic downforce. The results demonstrate that automatic downforce, which adjusts to field conditions in real time, provides a yield advantage.

“On average, when downforce is too light, we see a yield reduction of about 13 bushels per acre when compared to automatic downforce,” Lee says. “By contrast, we see a 2- to 3-bushel-per-acre penalty for heavy downforce. So, if you aren’t running a planter with automatic downforce and want to err on the side of caution, set your downforce on the heavy side.”

Takeaway No. 3: Uniform seed spacing increases yield

In addition to uniform emergence, the uniform spacing of corn plants within the row is crucial to maximizing yield potential. Evenly spaced plants result in equal competition for essential resources, allowing for optimal growth. The result is more bushels per acre.

“We want to avoid what are referred to as ‘skips’ and ‘doubles,’” Lee says. “Skips occur when the planter doesn’t drop a seed, resulting in a missing plant and no ear whatsoever. Doubles occur when the planter drops two seeds close together. The result is two smaller ears that don’t produce the same yield as ears that evenly spaced plants can produce.”

A planter’s ability to drop one seed at a time is referred to as seed singulation. Crop Tour field demonstrations have compared plots planted at two singulation rates – 93 percent and 99 percent using the vSet metering system.

“Our five-year data show that 6 percent reduction in singulation results in a yield loss of about 5 bushels per acre,” Lee says. “So, growers really want to avoid skips and doubles.”

Crop Tour 2021: New year, new questions

Lee adds that while the AGCO team will continue many of the field trials from the past five years, some new questions are likely to be posed in 2021.

“We’re still working out details, but we’d like to do some plots comparing plant populations, the impact of starter fertilizer, as well as differences between types of tractor tires and tracks,” he says. “The whole team is excited to ask new questions, help growers improve their planting practices and ensure their corn crops reach full yield potential.”

Click Here for Field Report #1: Tractor and Planter Compaction

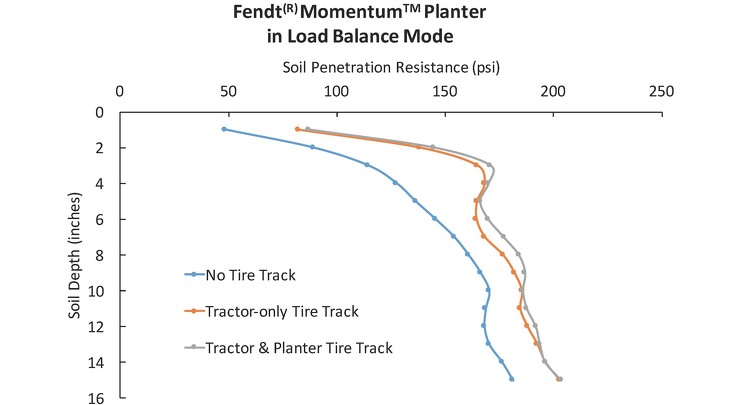

Penetrometer readings show how tractor and planter tires compact the soil:

Soil compacted at planting can reduce yields by restricting root growth and reducing nutrient and water availability. Soil compaction caused by wheel traffic has become an increasing concern among farmers, especially due to the weight of high-capacity, central-fill planters on the center transport wheels. Demonstrating just how much compaction can occur, how it impacts yield and how to minimize compaction at planting are goals of the AGCO Crop Tour program in 2020.

AGCO agronomists are observing crop development and measuring yield at Fendt Momentum Crop Tour plots throughout the Corn Belt this summer. In one of their first observations, the agronomists used a soil penetrometer to measure compaction caused by the tractor/planter compared to compaction in areas where the planter did not run (See Figure 1). Penetrometers measure resistance in pounds per square inch as the device is slowly pushed into the ground, simulating a root penetrating soil. The more resistance to the penetrometer, the harder it will be for roots to grow and penetrate soil. Readings were collected in five locations in Illinois, Ohio and South Dakota.

The plots were planted with a Fendt® Momentum™ planter equipped with the Load Logic™ system to distribute the weight of the planter, seed and liquid fertilizer across all the planter’s tires to lessen the load on the center transport tires and reduce compaction near the center rows. The planter’s in-line tandem center transport wheels were equipped with very high flexion tires and an auto tire inflation system that constantly adjusts tire PSI depending on planter weight to minimize pressure on the soil.

Figure 1.

Soil penetrometers provide an indication of soil compaction by measuring the resistance of the soil to the probe in pounds per square inch as the probe is slowly pushed into the ground. The plotted points represent the average of 15 readings in each track across plots located at Chillicothe, OH; Gridley and Pontiac, IL; and two plots in Baltic, SD. The tractor-only tire track was made by the inside dual wheel of the tractor, while the tractor-and-planter track was made by the outside tractor dual followed by the in-line tandem center transport wheels of a Fendt Momentum planter.

The chart shows that the planter added little to no extra compaction to that caused by the tractor tires. Many studies have shown that the first pass of equipment, such as the planter tractor, produces most of the soil compaction that occurs.

“These initial results support our goal of not causing added compaction with the planter in order to give corn and soybean plants their best shot at optimum yields,” says Jason Lee, AGCO agronomist and farm solutions specialist. “We will be taking plant measurements and hand-harvest estimates as the season progresses, along with harvest yield results this fall, to tell the full story.”

Wide, very high flexion tires equipped with an automatic tire inflation system on the in-line tandem central transport tires of the Fendt Momentum planter help reduce compaction.

Past research verifies yield loss due to compaction at planting:

Yield losses from compaction created at planting due to interrow wheel traffic from the tractor and planter can be substantial. In 2011, Pioneer on-farm trials determined average corn yields of rows planted by the outside wing sections of the planter were significantly greater than yields from the rows planted by the center planter segment in nine of 12 locations. In fact, the rows planted by the outside wing segments yielded an average of 11.3 bu/ac more than rows planted by the center section of the planter, due to interrow wheel traffic from the tractor and planter.

Click here for Field Report #2: Tire Pressure and Crop Height

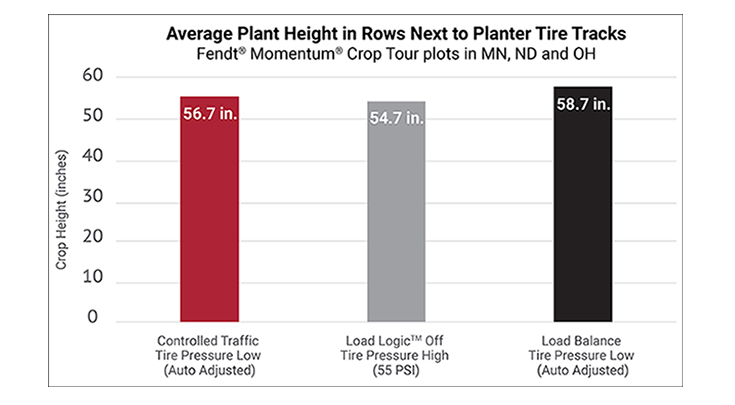

Three-inch variation in crop height between low and high planter tire psi:

This second 2020 Fendt® Momentum® Crop Tour field update reports AGCO agronomists’ observations of tire-track compaction on plant growth.

Soil compaction caused by wheel traffic is an increasing concern among farmers, especially due to the weight of high-capacity, central-fill planters on the center transport wheels. Several studies have documented plant height reductions caused by compaction, which restricts root growth, limits nutrient and water uptake and ultimately lowers yield.

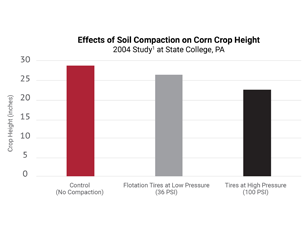

For example, researchers at Penn State1 reported that tires inflated to 100 pounds per square inch created compaction that reduced corn plant height at six weeks after planting by 21% compared to the control (no compaction), reducing grain yield by 11%. See Figure 1. In contrast, the researchers noted that flotation-style tires inflated to 36 psi “helped to reduce the effect of compaction on plant growth” to the extent that the crop height in that treatment was near that of the control.

In keeping with the 2020 AGCO Crop Tour™ goal to demonstrate the effects of and ways to minimize soil compaction at planting, AGCO agronomists have been observing crop development in plots in several states this summer. They recently recorded corn plant heights at growth stages after V12 to compare the compaction effects of various treatments.

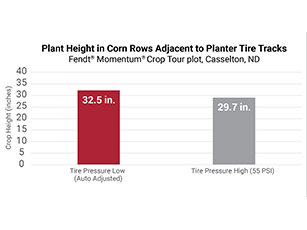

In a plot near Casselton, North Dakota, they compared two planter tire-pressure inflation rates: 55 psi, similar to the level for road transport, and automated inflation that maintained tire pressure at approximately 17 psi.

Jason Lee, AGCO agronomist and farm solutions specialist, measured plant height in the rows on either side of the in-line tandem center transport tires of the Fendt Momentum planter at low and high tire inflation pressure. He observed a near 3-inch height advantage in corn planted with very high flexion (VF) tires auto adjusted to maintain a low psi (approx. 17 psi), as opposed to the same tires kept at a constant 55 psi. See Figure 2.

To illustrate the difference in soil compaction at different tire inflation rates, please see the photo below that shows the footprints made by the same VF tire at 55 psi on the left and 15 psi on the right, the minimum inflation recommended by the tire manufacturer.

“Note that the length of the footprint increases as tire pressure decreases, reducing pressure applied to the ground and therefore potential surface compaction,” Lee says. “A larger footprint reduces the pressure to the soil and therefore lessens the potential for surface compaction damage.”

Evaluating correlation between plant height observations and yield

As the Casselton crop height observation suggests and many additional university studies have shown, tire inflation can make a difference in compaction and resulting plant height. Lee says he looks forward to taking the AGCO Crop Tour plots to harvest to see how final yields match with in-season observations.

Lee also says producers may want to consider lowering the inflation level of tractor and implement tires when possible before starting any field work. He acknowledges, however, that doing so means having an air compressor in the field and time to inflate tires back to road levels before transport, unless the equipment has a central tire inflation system, like VarioGrip™ on Fendt tractors or the tire inflation system available on the Fendt Momentum planter.

Figure 1.

Corn height at 6 weeks after planting in a 2004 study of soil compaction in conservation tillage at State College, Pennsylvania. A 6.3-inch height difference was noted between plants grown in soil with no compaction and in soil compacted by tires inflated at 100 psi. Height in treatments with flotation tires at low pressure was not statistically different from the no-compaction control.

Figure 2.

Average corn plant height around V12 when measured in the two rows on either side of the in-line tandem center transport tires on a Fendt Momentum planter in Casselton, North Dakota. In the “tire pressure low” treatment, the planter’s Load Logic™ system kept the very high flexion tires inflated at the lowest recommended level for the weight of the planter (approx. 17 psi); tires in the “tire pressure high” treatment were inflated at a constant 55 psi

Footprints made by very high flexion planter tires inflated at 55 psi (left) and 15 psi (right). Note the longer footprint at lower inflation pressure covers a larger surface area and lessens pressure applied to the ground.

Click Here for Field Report #3: Soil Compaction and Plant Height

Balancing weight evenly across planter can eliminate variability in corn row height.

In this third 2020 Fendt® Momentum® Crop Tour™ field update, AGCO agronomists report their observations of the effect of compaction on plant height.

Corn rows of uneven height can be a sign of compaction caused by planters. The weight of most high-capacity, central-fill planters is concentrated on the center transport wheels, causing excessive compaction on either side of the center wheel-track rows.

This compaction at planting, resulting in what is commonly referred to as pinch rows, restricts root growth on both sides of the row and reduces uptake of nutrients and water, often preventing plants from reaching their maximum height. Stunted plant growth above ground is often an indicator of what is occurring below ground, typically translating into yield reduction in the shorter rows, says Jason Lee, AGCO agronomist and farm solutions specialist.

Looking at ways to manage planter weight and compaction

In 2020, AGCO Crop Tour plots were designed to compare how different levels of soil compaction at planting affect plant growth and corn yield. Lee and the AGCO team planted three side-by-side plots in several states using the Fendt Momentum planter at one of three settings:

1. Load balance. The planter’s optional Load Logic™ system automatically monitors and hydraulically transfers weight equally to all wheels, while also automatically adjusting inflation pressure in the wide, very high flexion tires to the lowest manufacturer-recommended psi for the weight of the planter at any moment during planting.

2. Controlled traffic. The Load Logic system intentionally pulls the weight from the wings and concentrates it on the in-line tandem transport wheels, also with auto-adjusted low tire pressure. This setting is best for growers who strive to keep all field passes in precise traffic lanes to protect the rest of the field―and yield―from wheel-traffic soil compaction.

3. Disabled. With the Load Logic system disabled, the planter operates much like other central-fill planters, with the weight concentrated in the middle of the planter and tire inflation pressures at a static 55 psi, a common road-transport pressure level.

Because the same tractor was used to plant all three plots in a given location, any differences noted between plots could be attributed solely to the different planter settings described above. Tractor tire pressures also were maintained at a low PSI to minimize the soil compaction damage created by the tractor.

Compaction from load on center of planter stunts plant height

In the AGCO Crop Tour location near Chillicothe, Ohio, in particular, Lee says center rows were noticeably shorter in the plots planted when Load Logic was disabled (see top half of photo) or operating with controlled traffic settings. The height of corn planted with the planter at Load Logic’s load balance setting, however, was even across all rows (bottom of photo). Based on previous research related to pinch-row compaction, Lee says he would expect to see even greater differences in plant height if the corn had been planted with a central-fill planter with dual transport wheels, as opposed to the Momentum planter, whose in-line tandem center transport wheels eliminate planter-induced pinch rows.

To record plant height differences in the plots, AGCO agronomists measured the height of several plants in rows on both sides of the in-line tandem center transport wheel tracks in each of the three different plots. Figure 1 shows the average height differences due to compaction found in the Crop Tour plots in Pontiac, Illinois; Stewartville, Minnesota; and Casselton, North Dakota. When averaged across all three locations, corn in the center rows planted with equal weight on all planter wheels (Load Logic’s load balance setting) was, on average, 2 inches taller than center-row corn planted with Load Logic’s controlled traffic setting, and 4 inches taller than center-row corn planted with no weight management and with constantly high tire inflation pressure.

Check your fields for compaction

“Compaction severity is going to vary from year to year and from field to field,” Lee says, “depending on soil type, moisture conditions, tire inflation pressure, axle loads and more.” In addition to noting plant height variations between rows in fields, “a good way to assess pinch row compaction in your fields is to do hand-yield checks in rows between center transport wheel tracks and in rows with no compaction effects (no tire tracks on either side),” he says.

“Compare the yield differences in those two types of rows, then do that in multiple areas of the field to better assess if you are losing bushels to pinch-row compaction,” Lee says. If you see losses, he recommends considering lower tire pressures, not planting into wet soil and looking at technology changes to lessen soil compaction next season.

AGCO will continue to report AGCO Crop Tour plot progress, event updates and harvest results through farm media outlets, as well as via social media and online at www.fendt.com/us/planters/crop-tour, on Facebook at Fendt Global and on Twitter @Fendt_NA. Follow the hashtags #AGCOCropTour and #FendtMomentum. The Fendt Momentum planter will be on display at select dealer events and locations. For more information, visit Fendt.com or contact your local dealer.

Figure 1. Corn plant height in rows on both sides of the track from in-line tandem center transport wheels was on average 2 inches taller with equal weight on all wheels and low tire pressure (load balance) than center-row corn planted with planter weight concentrated on the center wheels (controlled traffic). It was 4 inches taller than corn planted with Load Logic disabled and high tire inflation pressure. Data: Average heights of multiple plants in the two rows on either side of the track from in-line tandem transport wheels of the Fendt Momentum planter in three 2020 AGCO Crop Tour locations in Illinois, Minnesota and North Dakota.

Shorter corn height (top) results from compaction in rows next to center transport wheels bearing the weight of central-fill planters, with tires at a static 55 psi. Corn height is more uniform (bottom), indicating less planter compaction, in rows where weight was distributed equally across all planter wheels and tire pressure was automatically adjusted to the lowest setting recommended by the tire manufacturer. Images from side-by-side passes at the AGCO Crop Tour plot location near Chillicothe, Ohio.

2020 Virtual Crop Tour

Thank you to all who tuned in to Fendt TV on Nov. 20, 2020, for the premiere of our 2020 virtual crop tour. If you missed it or would like to watch again, here is direct access.

2020 Fendt Momentum Crop Tour Sites:

Pontiac, IL (Precision Planting’s Precision Technology Institute/PTI)

Stewartville, MN

Chillicothe, OH

Lima, OH

Baltic, SD