Fendt Momentum

Configurator

Read Brochure

The Fendt Momentum 30-Foot Planter

Designed for smaller fields, with a groundbreaking 52" vertical range to tackle challenging terrain, making every single acre count, the Fendt Momentum 30' is a testament to human innovation and a boost to your bottom line.

With the highest capacity tanks in the 30' segment, 100 bushels of seed and 800 gallons of liquid fertilizer, you'll do more planting and less refilling.

No matter the size of your farm, Fendt's got you covered. The technology you want in the size you need, with the all-new Momentum 30' planter.

The potential for maximizing yield all starts with putting the seed in the ground and the details make all the difference, like ensuring accuracy no matter the field condition, or minimizing compaction, or simply covering more acres when they need to be covered.

Momentum Models

| 16 | 24 | 31 | 32 | 36 | 48 | |

| # of Rows | 16 | 24 | 31 | 32 | 36 | 48 |

| Row Spacing | 30" | 20", 22", 30" | 15" | 15" | 20", 22" | 15" |

The Fendt Momentum planter offers an optional 1,000 gallon liquid fertilizer system, allowing you to cover more ground and make fewer stops. Single band Precision Planting Conceal options can be equipped directly from the factory.

Higher capacity means fewer fills throughout the busy planting season, the Fendt Momentum features twin 65 bu. seed tanks for higher capacity and is easily accessed with a wide platform.

The Fendt Momentum planter offers an optional 1,000 gallon liquid fertilizer system, allowing you to cover more ground and make fewer stops. Single band Precision Planting Conceal options can be equipped directly from the factory.

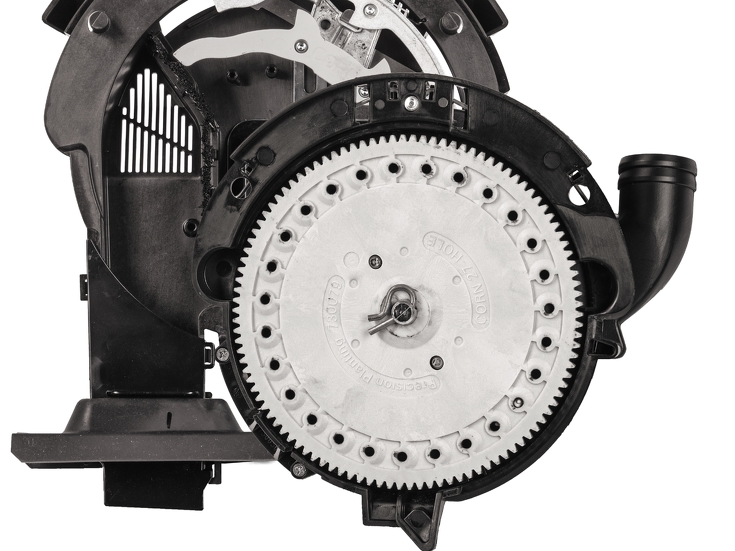

The vSet is easy to use, incredibly accurate and easy to maintain. It has an extremely high singulation accuracy.

The Conceal fertilizer application system is equipped with a single-sided application knife. The application knife is located between the depth control wheel and the double disc coulter. The application point is 3 inches beside the furrow at a depth of 0.75" to 1.5". As Conceal works directly next to the seed furrow, the application is perfectly placed next to the seed furrow, regardless of the terrain and cornering. A maximum of 71 GPM can be applied.

Monitor all planter functions and individual row unit performance in real time with the 20/20 Gen3 SeedSense® monitor system, which comes standard on all Fendt Momentum planters. , 20/20 SeedSense tells you what you need to know about population, skips, doubles, speed, row unit ride, down force and ground contact. It enables you to seed precisely, maintain depth, avoid compaction and troubleshoot mechanical problems.