The innovation at the time mounted a major challenge to powershift supremacy in the medium and high horsepower tractor sectors, and Fendt was instrumental in extending CVT availability to smaller tractors as well as its larger tractors (up to 380 hp models) for the next 20 years. There was a new mountain to climb, however. The demand for larger tractors grew as farm sizes increased, but larger tractors in the industry were specialized tractors—four-wheel drive, articulated and large track tractors. Fendt could sell track tractors in Europe, but articulated 4WD tractors were too wide for the narrow roads of Western Europe. The challenge was to find a solution to get high horsepower equipment down the road for transport and get enough traction to the ground. While CVT systems had a high degree of automation to control the interaction of engine and transmission, they were not yet designed to deliver traction efficiency between tractor wheels and the ground. They also had not been integrated with 4WD systems, and could not influence the torque ratio between the front and rear axle, which is usually fixed on conventional 4WD tractors. At the 2007 Agritechnica farm machinery trade fair in Hanover, Germany, the star of the show was the unveiling of the prototype Fendt TriSix tractor.

This milestone has allowed Fendt to extend its standard tractor portfolio up to 500 hp and supply a hyper-efficient CVT transmission that easily transfers power to the

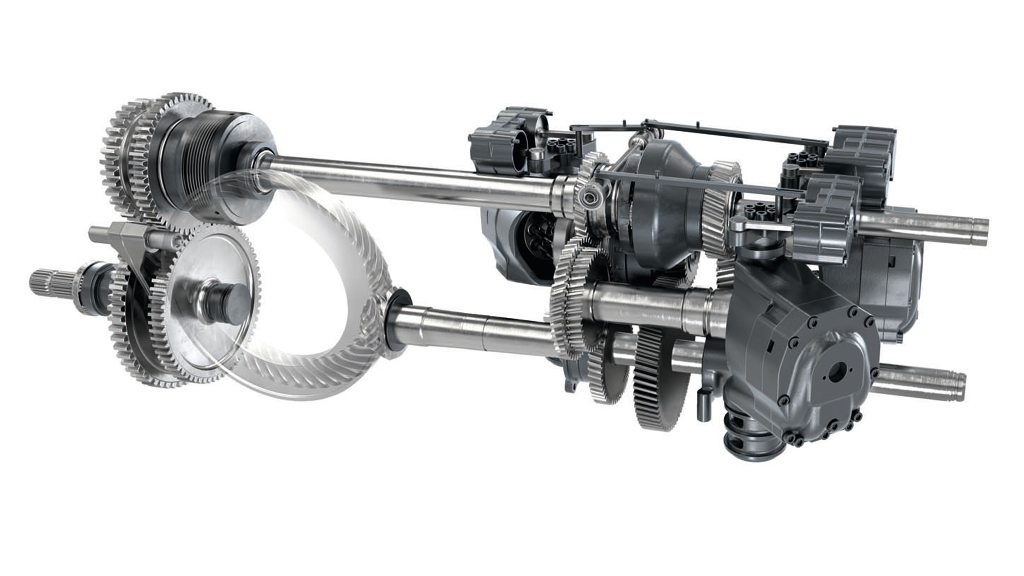

The solution was going beyond a CVT to a system that involves the whole drivetrain, including the axles and the 4WD system. By being able to distribute torque between the front and rear axle, power conversion and power distribution are merged to achieve optimum traction efficiency. The VarioDrive has one hydraulic pump and two hydraulic motors. The first motor is directly connected to the pinion shaft of the rear axle. The second is connected to the front axle. For high efficiency in transport, the second motor is disconnected by a clutch to avoid idling losses, and no range shifting is necessary. The front axle and rear axle are connected by an intelligent 4WD clutch which acts as an inter-axle differential lock. The 4WD is fully automated—on and ready to perform—allowing operators to concentrate on their work and never again forget to turn on the 4WD before a critical situation. As the engineers designed the VarioDrive innovation, the challenge of getting power effectively to the ground was met with one of the main innovations mentioned above: connecting the second hydraulic motor to the front axle to provide high torque at low speeds. When it came to designing the larger 4WD tractors VarioDrive made possible, Fendt needed a new range of tires that were row-crop capable. Putting 54-inch (1.37-meter) tires on 500 hp tractors had never been done before. Customers have the option of using very high flexion (VF) tires with the optional factory-installed Fendt VarioGrip CTIS to set and control tire pressure from the cab, which can reduce compaction while in the field, improve ride quality whether roading or in the field and reduce tire wear. Once all was designed, Fendt product management took on the challenge of convincing a large market that we could do more jobs or tasks with a single Fendt Vario tractor than with a large, articulated 4WD. Mission accomplished!