Additional hydraulic valves for Fendt 200 und 300 Vario

The Fendt 200 and Fendt 300 Vario models are equipped with a maximum of four hydraulic valves as standard. If a front loader is added, two of the available valves are already occupied. A retrofit solution is now available for all models in the Fendt 200 Vario Gen3 and 300 Vario Gen4 series with FendtONE, regardless of the equipment line. With the retrofit kit, farmers can equip their machine with two additional and freely assignable hydraulic valves. These are then fully integrated as the 5th and 6th EHS valves (brown and violet) into FendtONE. The two valves are installed in the rear of the tractor at the position of the yellow and blue valves. The multi-coupler in the centre of the tractor occupies the yellow and blue valves as usual. This means that farmers can use up to four valves to operate implements for grassland or arable farming when the front loader is fitted. In addition to the valves, the retrofit kit includes a cable set, the associated piping, colour clips for the valve caps and installation instructions and can be ordered from sales partners from Q3 2024.

Additional attachment space for tools and accessories

Tractors usually only have limited storage space outside. Storage capacities for a trailer hitch, a hand wash tank or cleaning equipment for the road or the implements are rarely available.

In future, farmers and contractors will be able to install a base plate on the right-hand side of the tractor with the chassis organiser for installing various transport brackets. A holder for the trailer hitch or a hand wash container with integrated soap dispenser can then be mounted on this base plate. Other options include a toolbox or a holder for brooms or shovels, for example. The chassis organiser and the corresponding attachments can be ordered from dealers from Q3 2024 and are available for the Fendt 300 to Fendt 700 Vario series.

Retrofitting side windscreen wipers

When mowing with a boom mower, working in heavy rain, wind or snowfall, the side windows of agricultural and municipal machines as well as when working on construction sites, in special crops or in forestry can become very dirty. Fendt now offers a retrofit solution for side window wipers. These can be installed on both tractors and harvesters. So far, only a few machines offer this option ex works on the right-hand side of the vehicle if no door is installed there. A side window wiper for windows on the left-hand side cannot yet be ordered. The retrofit windscreen wipers can be installed on both doors and windows using an adhesive connection. The retrofit package includes the wiper unit, a wiring harness with control unit and a wiper water tank. The wiper angle is calibrated using a diagnostic tool that is already available in the workshops. The side window wiper for retrofitting can be ordered from dealers from Q4 2024.

Accessories for the cab

Numerous attachments require additional terminals or control consoles. A MultifixBoard for the cab interior is now available for precisely this purpose. The Multifix board is simply screwed onto the terminal holder at the rear right. The universal hole pattern in the MultifixBoard enables the installation of RAM balls, commercially available plug-in pockets and holders, as well as device holders. Additional clips ensure neat cable routing, while a cut-out window allows a view of wide implements such as a mower or seed drill.

In addition, CabMount is a RAM ball adapter for mounting different operating terminals or a screen for displaying a camera image on the A-pillar. The CabMount can also serve as an attachment point for an additional cup holder. Customers can order the MultifixBoard and the CabMount adapter from their sales partner from Q2 2024 and are available for the Fendt 300 Vario to Fendt 700 Vario series.

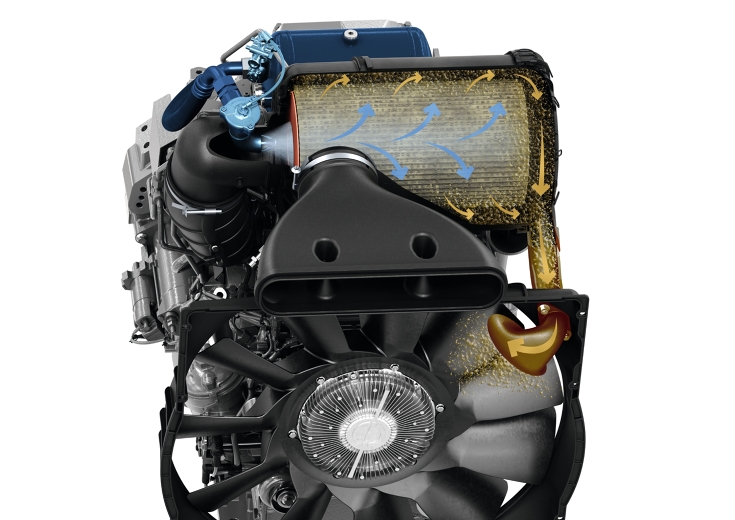

Self-cleaning air filter for Fendt 900 Vario Gen6

Fendt offers a self-cleaning air filter as a retrofit solution for machines in the Fendt 900 Vario Gen6 series for use in regions with particularly high dust levels. The retrofit solution is fully integrated into the terminal and is recognised as an ISOBUS device. It is controlled directly via the terminal.

The filter system combines continuous dust extraction with active cleaning of the filter. The filter is blown out on the move, to avoid any downtimes usually associated with manual filter cleaning. The filter is blown out twice during the cleaning cycle. The dust filter has its own compressed air tank. The compressed air flow is controlled by a solenoid or pulse valve. Just before blowing out, the speed of the fan is raised and continues running like that for a short while afterwards. This increases the cleaning effect. Cleaning can be carried out fully automatically or manually if required. Components from the Fendt 900 Vario Gen7 series, which were specially developed for this system, are used for installation.

The self-cleaning air filter as a retrofit solution for machines in the Fendt 900 Vario Gen6 series will be available from dealers from Q3 2024. The scope of delivery includes all components such as a new air filter housing, valves, the pressure accumulator, a cable set and a control unit for smooth integration.

Fendt 900 Vario Gen6