Since they were launched in Germany in 2002, the Fendt square balers have enjoyed an excellent reputation for their rugged and durable design as well as high output. When developing the next generation, the focus was on further improving these positive properties, optimising operation and simplifying maintenance. A new series has been developed that unites all of these requirements and is also exceptionally well adapted to the Vario tractors in terms of their design and technical specifications.

High performance with absolute reliability

The first square baler left the factory in Hesston, Kansas, over 35 years ago. It laid down the foundation for one of the greatest success stories in harvesting technology. The Fendt square balers have been produced here, in the sole possession of the AGCO Corporation, since 2000. Based on decades of experience in development and production, they are distinguished by stability, durability and perfected technology. Through continual, practice-driven improvements, Fendt can offer you a choice of six high-capacity balers today.

| Bale size (width x height) | |

| 990 | 80 cm x 90 cm |

| 1270 | 120 cm x 70 cm |

| 1290 | 120 cm x 90 cm |

| 1290 XD | 120 cm x 90 cm |

| 12130 | 120 cm x 130 cm |

Fendt Early Bird 2026 – Being fast does pay off!

For highest speeds and maximum throughput

The basis for perfectly compressed bales

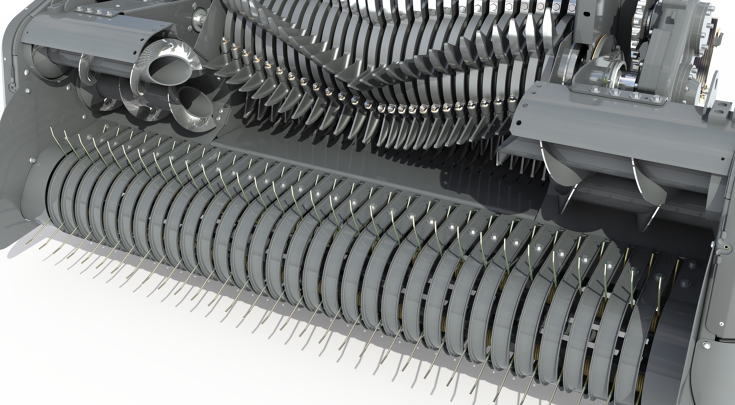

The crop pickup plays a decisive role in the performance of a baler. The 2.26 m wide pickup on the Fendt square balers ensures clean crop pickup from the very beginning. Then the centring augers guide the material effectively into the pre-compression chamber. This guarantees a high output.

Xtra Density – the high-output baler

35 percent heavier main gearbox

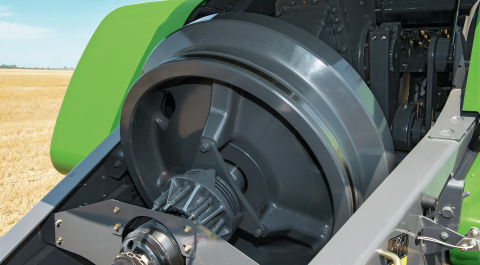

In order to achieve a higher bale weight with a higher output, many things have been optimised in the XD. Strengthening the drives, such as the main gearbox, chains and gears stood in the foreground during development. In particular, the new XD flywheel, which weighs 545 kg, is almost twice as heavy as the standard version. New plunger arms ensure safe transfer of the higher forces. All together, this makes it possible to exert more force on the plunger. The counter piece, the bale chamber, also has several improvements that increase friction. These include a 40 cm longer bale chamber, stronger hydraulic cylinders and optimised bale chamber flaps. Another example would be that the turning point of the side walls has been positioned further back to generate more friction on the sides.

Typical Fendt – everything in place

At Fendt, innovations are not only found in key technology, but also in the details and the ease of maintenance. The large bonnets permit perfect access to the machine for maintenance work. When it turns dark, additional lights under the bonnet aid the operator. Automatic knotter and chain lubrication are also part of the operator friendly maintenance of the square baler, in addition to the long-life alignment of the chains and drives.