New models & Product highlights

product innovation

The new Fendt Former twin rotor rake

With smarter technology and the Fendt factor for new dimensions. The new generation of Fendt Former centre delivery rake includes standard models for those not needing ISOBUS functionality through to smart models for farms with high ISOBUS performance requirements.

PRODUCT INNOVATION

The Fendt 600 Vario – naturally superior

For our brand new innovation, the Fendt 600 Vario, we bring nature and technology into perfect harmony. The all-round tractor in the medium power segment was presented live for the first time at AGRITECHNICA 2023.

PRODUCT INNOVATION

The Fendt e100 V Vario: Think ePossible

The time had finally come: With the Fendt e100 V Vario, we presented the first electric tractor from Fendt at AGRITECHNICA 2023. Emissions-free, powerful, compatible – recognise the new opportunities for your farming and for a sustainable future today. Find out the first details about the new Fendt e100 V Vario now and see for yourself!

Product INnovation

Fendt Slicer 960/1010

PRODUCT INNOVATION

Fendt Former centre rake with ISOBUS Integration.

The new Fendt Former twin-rotor centre delivery rakes represent a significant development in making grassland management more efficient and productive. The series uniquely combines pioneering ISOBUS technology with proven features such as the patented SteerGuard steering system and the robust double swing arm.

Specials & Offers

AGCO Parts

Stock up & save: 10% discount

Prepare now for a productive season ahead. Buy online to get 10% off quality wear parts, consumables, accessories and more. For spends over £250, maximum discount £50 per order. Offer ends 30th April.

AGCO PARTS SHOP

Right Fit, First time, Every time.

You can now buy replacement parts, lubricants, and many other farming products online via our AGCO Parts Shop. Browse, purchase, and arrange delivery or collection at your convenience.

PROMOTION

The Fendt Tigo won them over in the practical test - Secure the winner's bonus now!

In a practical test with a comparable competitor, the Fendt Tigo 90 XR D delivered absolute top values! That is something to celebrate! Find out more about the test results and secure an attractive winner's bonus on your new Fendt Tigo.

Fendt tested

Fendt 700 Vario gen7 on test

Dreamed, built, tested

Experts and the trade press are convinced by the Fendt 700 Vario Gen7. Not for nothing has it been honoured with awards such as Farm Machine 2023 or Tractor of the Year 2023. The completely newly developed 700 series has been extensively tested and the 728 Vario is considered the number one most economical tractor in transport. Now there are also voices from the neutral trade press, which have published the detailed test reports.

Fendt Tigo on test

When TIM sets the pace

In May 2024, the Fendt Tigo 90 XR was put to the test in the agrarheute Pflanze+Technik test and was particularly impressive with Tractor Implement Management (TIM), Fendt Stability Control (FSC) and VarioFill. Find out how Fendt TIM and VarioFill technologies relieve the driver and why FSC is so important in the May issue of Pflanze+Technik from agrarheute.

Fendt Rotana on test

“Baling without stress”

The Fendt Rotana 180V Xtra scored particularly well in the agrarheute Pflanze+Technik Test with its Tractor Implement Management (TIM). The low-maintenance design is another impressive feature of the baler: “The central lubrication system ensures low maintenance costs. This means that all press roller bearings are automatically lubricated.” Learn more in the test report.

News Center

Fendt World

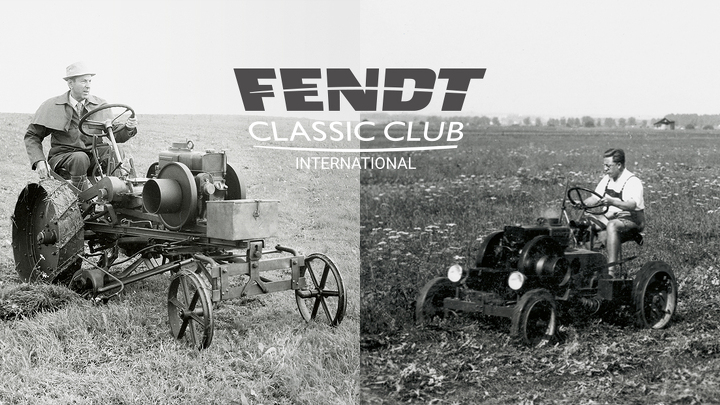

FENDT CLASSIC CLUB INTERNATIONAL

The new Fendt Classic Club International

Smart Farming

FendtONE - The seamless connection of office and machine.

Smart interaction between the digital FendtONE platform and the new driver's workstation, closely linking your everyday work life on the machine with your office tasks.

NEW Tractors

Fendt 1100 Vario MT

Get it done. The Fendt 1100 Vario MT is the first tracked tractor in this hp class to have a stepless drive.