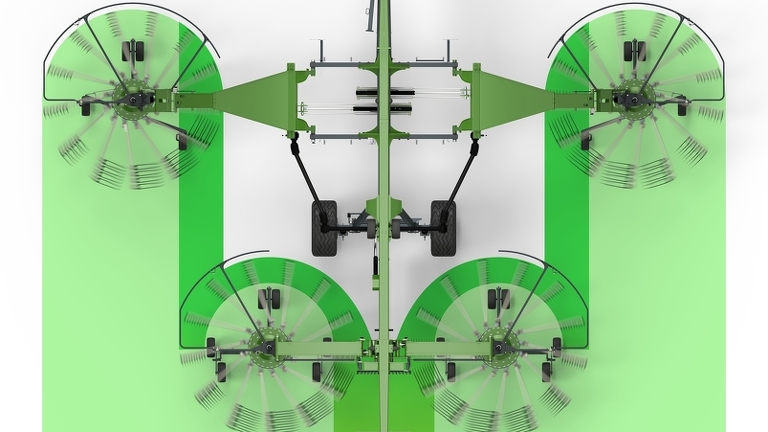

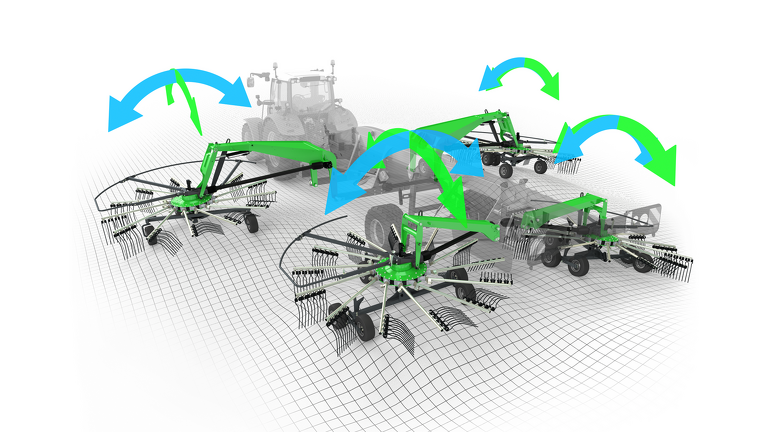

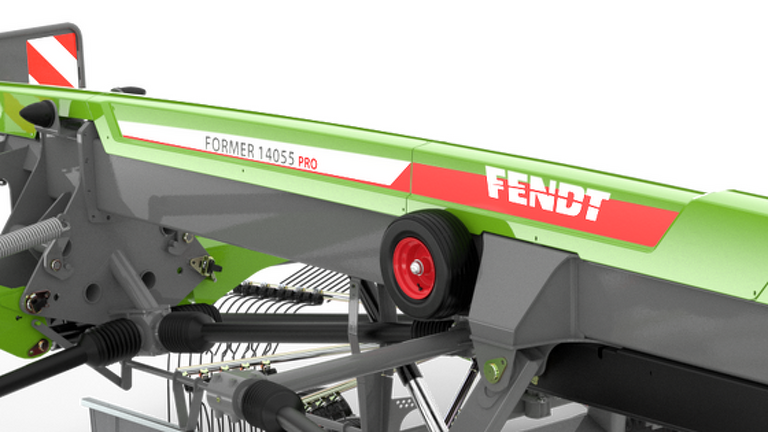

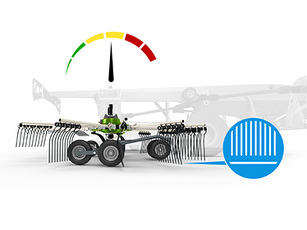

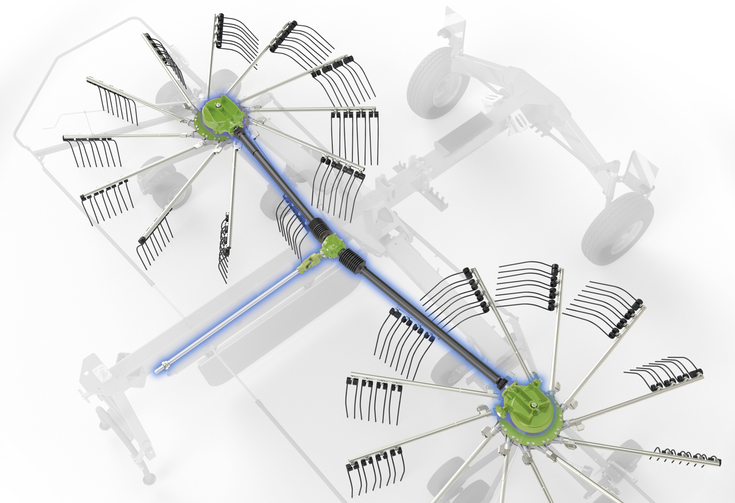

The Fendt Former two-rotor rakes with centre swath delivery are available for every harvesting requirement. They are impressive in all performance segments - from the entry-level model Former 671 with low power requirements to the all-round models Former 760 C, 860 C and 920 C, as well as the professional machines Former 860 PRO, 920 PRO and 1000 PRO. These versatile machines are characterised in particular by their raking quality, high flexibility of use, wide range of variants and intuitive operation.

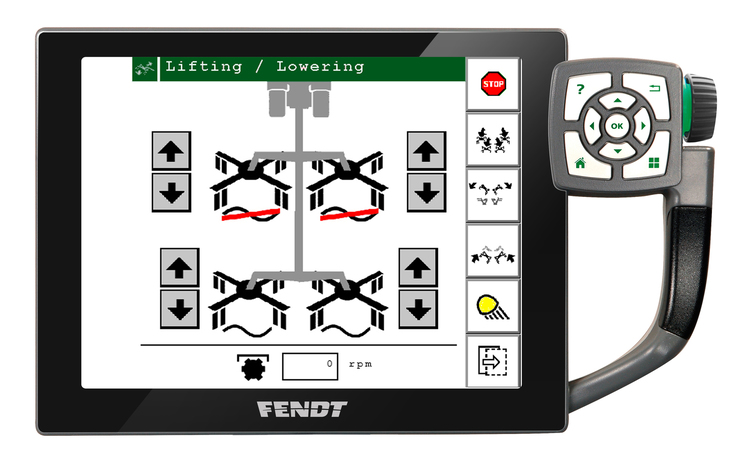

Swathing with the Fendt factor - unique ISOBUS technology.

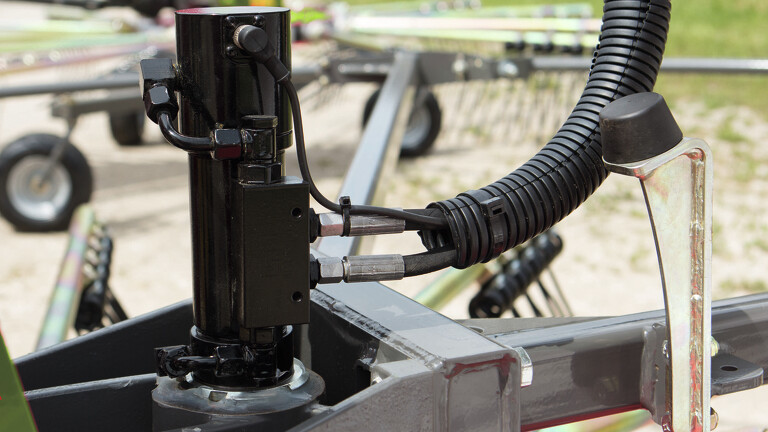

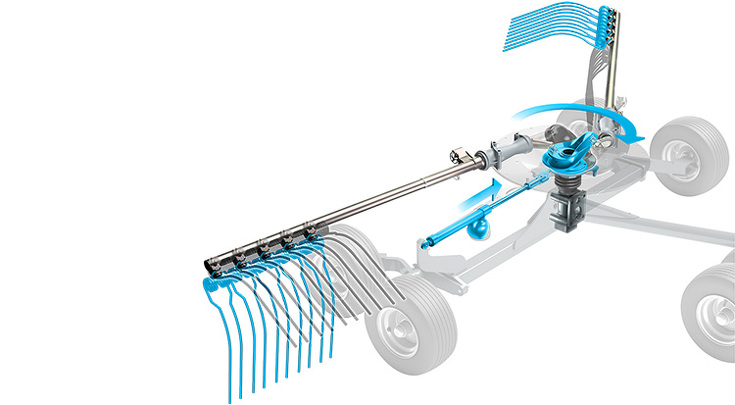

The integration of ISOBUS in this rake category is a milestone. It enables the automatic adjustment of work processes directly from the driver's seat. The new intuitive user interface makes operation child's play. The new Fendt Former twin-rotor centre-swath rakes thus represent a significant

development to make grassland management more efficient and productive.

| Working width | Tine arms per rotor |

Former 671 | 5,80 - 6,60 m | 10 / 10 |

Former 760 C | 6,90 - 7,60 m | 12 / 12 |

Former 860 C | 7,60 - 8,60 m | 13 / 13 |

Former 860 C PRO | 7,60 - 8,60 m | 13 / 13 |

Former 920 C | 8,00 - 9,20 m | 14 / 14 |

Former 920 C PRO | 8,00 - 9,20 m | 14 / 14 |

Former 1000 C PRO | 8,80 - 10,00 m | 15 / 15 |