Crop protection has never been better.

The Fendt Rogator 600 is impressive in every respect. Thanks to its design, it can cope with a wide range of conditions. Whether it's challenging conditions in the field or tall crops – the Fendt Rogator 600 is up to the task. Thanks to its adjustable ground clearance and unique four-wheel drive, it can overcome any obstacle. In combination with the intelligent boom height management, the crop can be processed perfectly.

The Fendt Rogator 600.

Model overview

| Rogator 645 | 173 kW* | 235 hp* | 5000l** |

| Rogator 655 | 200 kW* | 272 hp* | 5000/6000l** |

| Rogator 665 | 226 kW* | 307 hp* | 6000l** |

*Maximum power according to ISO 14396

**Nominal performance

Manoeuvrable.

Precise.

Gentle.

Fendt Rogator 600 – crop protection technology perfection

Optimum crop protection does not just start in the field. It starts with choosing the right machine. The Fendt Rogator 600 combines crop protection technology and efficiency. With its balanced weight distribution, 35° steering angle, all-wheel steering, height-adjustable chassis and optional adjustable track axle, it adapts perfectly to all conditions. The HydroStar CVT enables precise spray applications, while the intelligent four-wheel drive ensures the best possible drive. Thanks to the standard all-wheel steering, the front and rear axles run perfectly in one track, which minimises crop damage. Perfect for versatile applications in crop protection.

Visionary and practical

The AGCO Vision cab with its curved windscreen, thin pillars and large glass surface provides a better view.

6.4 m²

Glass surface

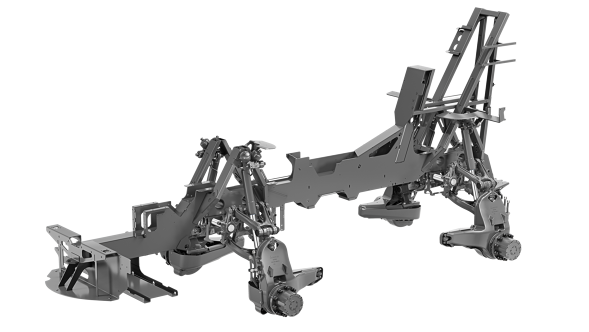

Chassis

The single carrier chassis is the key to many of the advantages of your Rogator 600. It keeps the centre of gravity low by positioning the engine between the axles. It ensures a large steering angle even with wide tyres and keeps the outer width narrow. The 50:50 weight distribution ensures that your Rogator 600 is always gentle on the ground.

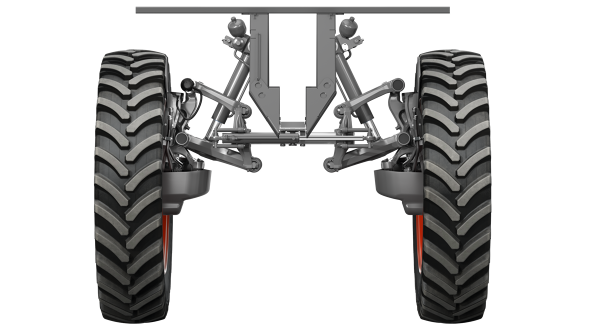

Single wheel suspension

Good for the crops, the soil and the driver: the patented independent wheel suspension of the Rogator 600 has been specially adapted and is fitted as standard. It helps to keep the machine at the optimum height from the crops. It gives you the choice between 75 cm or 120 cm ground clearance – simply at the touch of a button and regardless of the track width. You will feel a significant increase in comfort from the very first moment you set off.

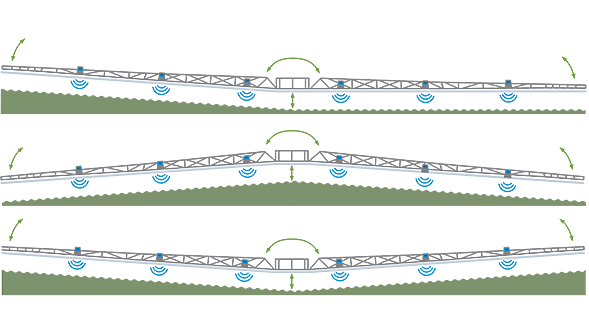

Ideal positioning at all times

Everything is designed for precision and an exact distance to the target surface: The OptiSonic boom height control actively controls the centre frame and thus avoids deviations from the desired target surface distance even more effectively. The special combination of gas pressure dampers and rubber blocks gives the frame outstanding stability and efficiently prevents horizontal movement. With 4 or 6-sensor options, OptiSonic guarantees precise detection of the terrain and enables adaptive adjustment of the boom for even more precise and uniform application of pesticides.

Boom widths and special folds

How much impact can it have? With boom widths from 24 to 39 metres, you have the choice – and the same even goes for folding! The booms are double or triple-folded, special folds are available. If things get too tight, the standard collision protection prevents damage to the booms.

24-39 m

Boom width

Single nozzle control as standard

The Rogator has a large selection of nozzle holders. Depending on the nozzle holder, one or more nozzles can be controlled electro-pneumatically. So the sky’s the limit with SectionControl and VariableRateControl, The nozzle spacing is 50 cm, which minimises overlapping at the headland. This helps you to use your pesticides as efficiently as possible.

OptiNozzle

The perfect nozzle or nozzle combination at all times – with OptiNozzle this is completely automatic. The Fendt Rogator 600 selects the right nozzle or nozzle combination based on various application parameters. It takes the legal requirements for drift reduction as a foundation.

Speed Control

SpeedControl automatically adjusts the speed depending on the nozzle combination, so that the pressure at each nozzle is always just right. This not only ensures the precise application of pesticides, but also the efficient utilisation of resources.

Fendt TaskDoc

Fendt TaskDoc offers more options for optimised documentation. With GPS recording and specific settings sent over the mobile network, the key data is documented instantly and directly. This enables the automatic, seamless exchange with ISOXML-compatible field management software and mapping. Data including remaining time, remaining surface area and fuel required is sent and shown on the Varioterminal while you are working.

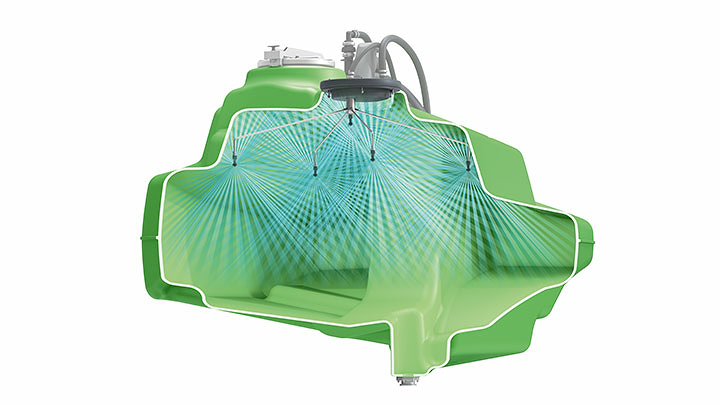

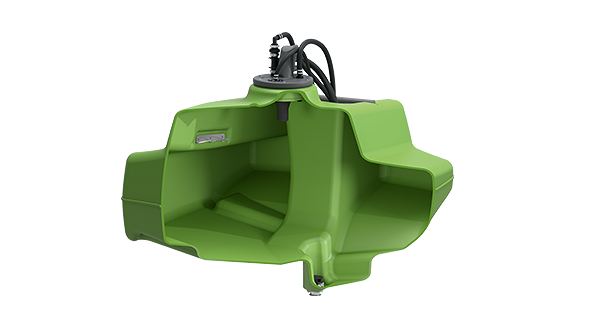

Excellent tank properties

You can see it at first glance: The product spray tank is wide and flat, improving the centre of gravity and thus the driving stability of the Rogator 600. It is made of the particularly durable polyethylene material LMDPE and is at least 12 mm thick at all points. The corners are specially reinforced. You can clean it seamlessly – smooth surfaces prevent pesticide residues.

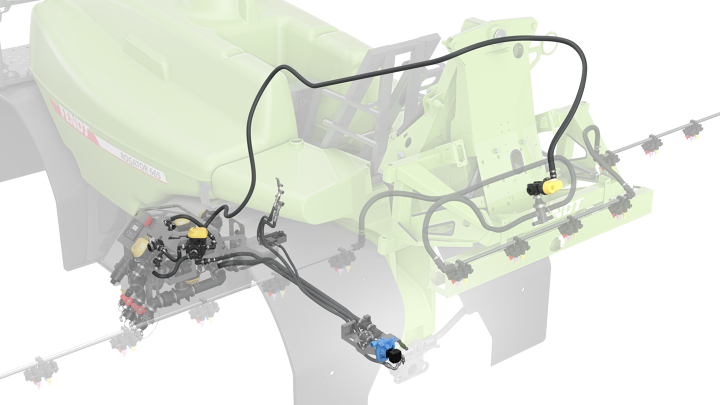

Simple tank filling

All filling and return hoses pass through a single, central tank manifold. This reduces maintenance work and maximises convenience when filling. The sophisticated design not only enables time-saving filling, but also helps to minimise potential sources of error, which increases the reliability of the overall system.

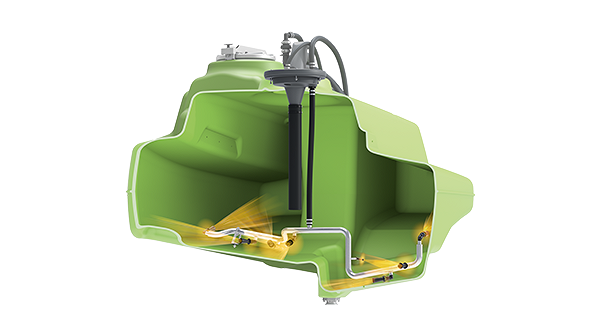

Effective agitation

Leave the agitation entirely to the technology. Smart nozzles based on the Venturi principle ensure maximum agitating force – without any impairment of the application rate. This minimises foaming, which not only improves the efficiency of the mixing process, but also promotes the homogeneity of the spray solution and thus contributes to a precise distribution of the spray products.

Clean water tank

The Fendt Rogator 600 carries up to 660 litres of fresh water. Thanks to the pressure sensor, you can see exactly how much is on board at any time electronically. You simply fill it with a separate connection to the OptiFlow filling station and the precise electronic monitoring of the filling level enables efficient planning and implementation of crop protection measures.