With Fendt VarioGuide you can drive reliably and accurately, even in areas with difficult reception conditions. Fendt VarioGuide permits the highest possible utilisation of your machines, because you can work without actively having to steer, even at night or with large working widths. With VarioGuide, the tractor automatically maintains the ideal line so that you can concentrate fully on the implement. Overlapping is reduced and, depending on the working procedure, savings of three to ten percent can be achieved. Depending on the application, you can work with two different accuracy levels: the VarioGuide Standard achieves a precision of approx. 20 cm, while the VarioGuide RTK delivers 2 cm accuracy.

Always on the ideal track

Unique flexibility in receiver selection

With Fendt VarioGuide, there are now two different receiver systems available, NovAtel® and Trimble®. The VarioGuide steering system ensures optimum work results and maximum comfort. With the NovAtel receiver, the correction signals SBAS, TerraStar-L & C and RTK keep you on track. Choose a Trimble® receiver to use SBAS, RangePoint™ RTX™, CenterPoint RTX™ and RTK. If you lose your RTK signal due to the terrain, VarioGuide continues to work reliably up to 20 minutes thanks to the Trimble®-xFill™ or NovAtel® RTK Assist solution.

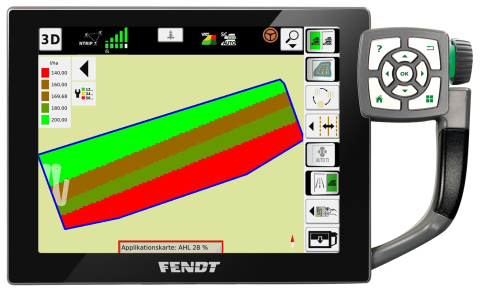

With VariableRateControl (VRC), you can farm according to site-specific application maps, depending on the ground and crop. So you can save on inputs.

One terminal for everything: 100% ISOBUS compatible

The Fendt Varioterminal communicates with all ISOBUS standards. You can control all ISOBUS-capable implements on only one terminal – and enjoy all the additional benefits of a range of features – from documentation up to section control. In short: You are completely flexible with only one terminal.

Your work at a glance with Fendt VarioDoc

Documentation is the most important basis for farm management for agricultural businesses. With VarioDoc, relevant data can be recorded with a minimum of effort, documented in the field record and then analysed, all in the shortest amount of time. The data is transferred wirelessly from the Varioterminal to the field database using the ISOBUS Standard TC-BAS. Data on the quantity of seeds and fertiliser applied or the fuel consumption per hectare is available immediately after the work is done. Additionally, jobs can be created in the PC and sent to the terminal.

Documentation in realtime: Fendt VarioDoc Pro

More options with the Fendt VarioDoc Pro documentation. With GPS recordings and specific settings sent over the mobile network, the key data is documented instantly and directly. This enables the automatic, seamless exchange with ISOXMLcompatible field management software and mapping. Data including remaining time, remaining surface area and fuel required is sent and shown on the Varioterminal while you are working.

VarioDoc enables wireless data transfer from the Varioterminal to the field database. VarioDoc Pro continually records position and machine data and data transfer is possible via mobile network.