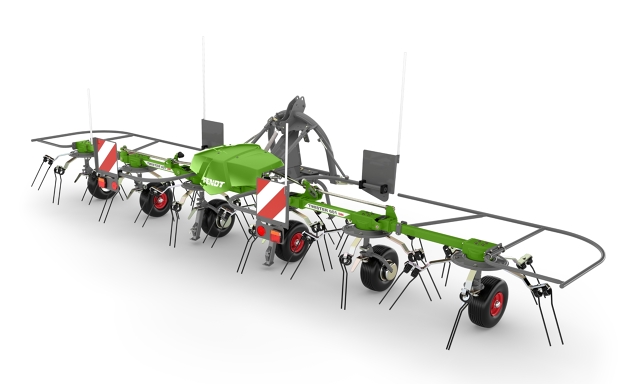

The Fendt Twisters can all be used with four, six, eight, or ten rotors in three-point mount. Working widths of up to 10.72 m are no problem. Fendt Twisters are however really compact in the transport position. The synchronous rotor lifting makes it much safer and easier to fold and open the rotors, even on slopes. The rotor speed can be reduced using the optional night swathing gearbox, to shape the perfect night swaths while ensuring excellent area coverage, and to protect the crop against moisture – perfect for small harvest time windows and heavy dew.

Working width | Rotors | Tine arms per rotor | |

Twister 431 DN | 4,30 m | 4 | 6 |

Twister 601 DN | 5,70 m | 6 | 5 |

Twister 5204 DN | 5,20 m | 4 | 6 |

Twister 6606 DN | 6,60 m | 6 | 6 |

| Twister 7706 DN | 7,70 m | 6 | 6 |

| Twister 8608 DN | 8,60 m | 8 | 6 |

| Twister 11010 DN | 10,72 m | 10 | 6 |