The Fendt Rotana 130 F Combi stands out in every aspect. The bale chamber has a shallow tilt angle, which provides excellent stability, especially on slopes. The shallow tilt angle also means optimal crop flow and output. High operating speed is the second ace in the pack. Using the fully-automatically adjustable wrapping system, the machine measures the bale diameter during net tying, and the optimal number of plastic film layers is calculated in the same step.

Because some things in life are simply the best.

Quality that inspires

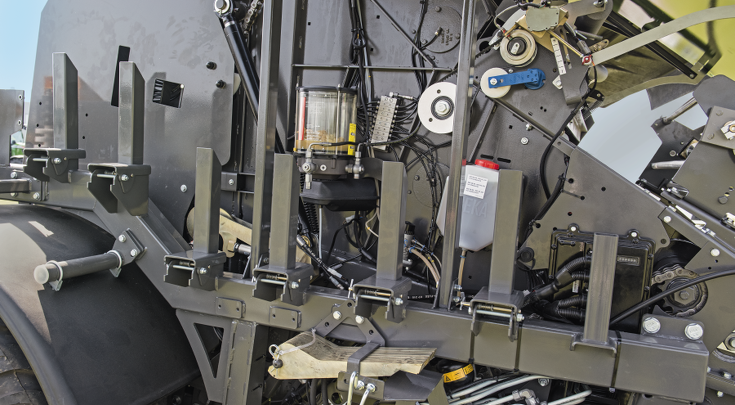

The Fendt Rotana 130 F Combi combines balers and wrapping with maximum quality, precision and efficiency. The tried and trusted baling technology of the fixed chamber round baler forms the heart of this machine. You'll love this machine with all the key features of the proven round baler, like the robust Power Split gearbox in an oil bath and the cam track-free pickup for the perfect forage pickup and best crop flow. The 18 PowerGrip steel rollers and mechanical tailgate lock guarantees perfectly formed bales and bale densities. Blockages are also a thing of the past on this machine thanks to HydroflexControl. The feed channel floor can move down slightly to allow stones or forage to pass through.

Because some things in life are simply the best.

Quality that inspires

The Fendt Rotana 130 F Combi combines balers and wrapping with maximum quality, precision and efficiency. The tried and trusted baling technology of the fixed chamber round baler forms the heart of this machine. You'll love this machine with all the key features of the proven round baler, like the robust Power Split gearbox in an oil bath and the cam track-free pickup for the perfect forage pickup and best crop flow. The 18 PowerGrip steel rollers and mechanical tailgate lock guarantees perfectly formed bales and bale densities. Blockages are also a thing of the past on this machine thanks to HydroflexControl. The feed channel floor can move down slightly to allow stones or forage to pass through.

Irresistible arguments

Bale transfer made easy

Tailgate up and out. Bales are carefully transferred to the wrapping table by the actively movable panels and a transfer arm. This design is suited in particular to slopes. The machine adjusts to the speed of the transfer arm, and places the side plates at a steeper angle so that the bales can be guided to best effect. The wrapping ring also acts as a guard so that bales do not fall from the wrapping table. This is what ensures an optimal wrapping process in any conditions.

Pure flexibility

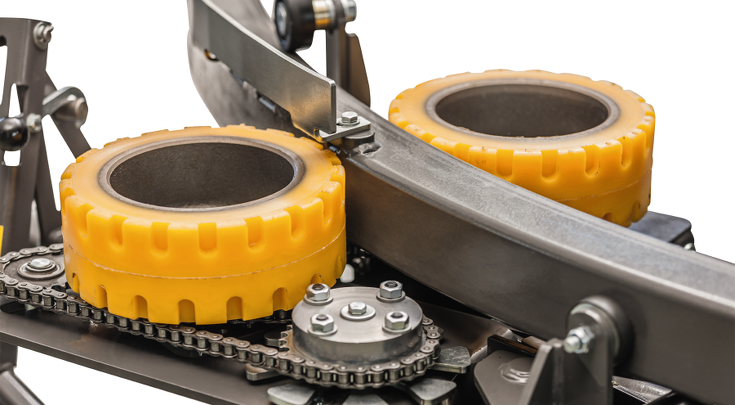

A smooth-running drive means little maintenance. The wrapping ring is therefore guided and driven by rubber rollers. Two other hydraulically-driven rollers ensure that the guiding and tension of the ring remains constant. The entire wrapping ring is also mounted on rubber rollers. The subsequently smooth and even running gives the drive additional reliability with very low drag and secure bales. The best conditions for precise and quick wrapping.

The solution for fast wrapping.

Wrapped in seconds

The Fendt Rotana 130 F Combi only starts the wrapping process when the bales are secure on the wrapping table. Two rollers and three infinite belts rotate the bales safely on the wrapping table. Four plastic rollers on the sides also keep the bales in position. To get the right wrapping for any forage, you can change the pre-tension of the plastic film quite easily by shifting gear. Choose between three plastic film tensions: 55%, 70% or 90%. Thanks to the intelligent wrapping system and a sensor roller, the optimal number of plastic layers are wrapped around the bales, with an even overlap of each layer.

Small details make all the difference

In order to offer the right cutting/clamping device range for any plastic film height, the Fendt Rotana has a two-stage device with an extremely wide opening. The special locking mechanism ensures that the film is held very securely, to allow a perfect cut and to hold it in the right position. If the film tears, the bales can be wrapped using the remaining plastic or the ring pauses to allow the film to be repaired. The process works with the aid of a film sensor programmed from the hand set.

Careful delivery

In order to guarantee maximum bale quality, the wrapping table moves down as far as possible and bales delivered close to the ground. The bale mat delivers the bales slowly and carefully behind the machine without risking damage to the plastic from the stubble. The bales lie securely on the ground and do not roll away on steep terrain. Front delivery can also be used as an option. You can also compress bales quite normally if the wrapping ring is raised.

Simple and compact

Narrow roads and bridges are no problem for the Fendt Rotana. Despite the large tyres, the 2.80m transport width still gives you flexibility. The large tyres also provide optimal soil protection, and protect the sensitive sward and soil, especially when turning.

The Fendt Rotana FC has 620/55 R 26.5 tyres for optimal ground following and safe road driving.