The Cutter front mower is a huge favourite, especially for green fodder recovery. Combined with a Fendt loader wagon, this gives you superior quality feed for your animals, with the best sward protection. And you can have plenty of fun in the process.

Forage harvesting non-stop.

With the Fendt Cutter drum mower.

The perfect cut is the foundation of quality forage. With the Fendt Cutter drum mowers, the perfect cut is easy as 1-2-3, regardless of the conditions. The key features of the Fendt Cutter include the proven technology, great durability and new, smart details which make work easier.

Fendt Cutter Front Mounting

Fendt Cutter FPV: Front-mounting with swing linkage

| Cutter 2940 FPV | Cutter 3140 FPV | Cutter 3340 FPV | |

| Working width (m) | 2,86 | 3,06 | 3,26 |

| Cutting drums (Number) | 4 | 4 | 4 |

| Baldes per cutting drum (Number) | 3 | 3 | 3 |

Fendt Cutter FPV: Front-mounting with swing linkage

Flexible width

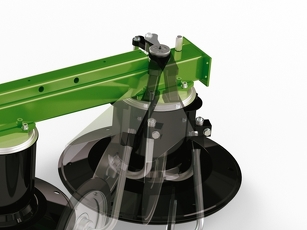

The mowed swatch can be perfectly adjusted to the following work steps using the flexible swath width adjustment. Using a central adjustment lever on the top of the mower, you can quickly and easily adjust the swath width from 1.2 to 1.75 m depending on the model, by swivelling the two swath discs. Additional swath discs are available as an option, and form an even narrower swatch from 0.65 m to 1.4 m depending on the model.

Flexible width

The mowed swatch can be perfectly adjusted to the following work steps using the flexible swath width adjustment. Using a central adjustment lever on the top of the mower, you can quickly and easily adjust the swath width from 1.2 to 1.75 m depending on the model, by swivelling the two swath discs. Additional swath discs are available as an option, and form an even narrower swatch from 0.65 m to 1.4 m depending on the model.

Adjustable by hand

The easy cutting height adjustment comes standard on all front mowers. On mowers with a front pendulum block, the height can be infinitely adjusted from 45–73 mm by turning the wear-resistant skid plate. A practical tool is always kept close at hand on the machine.

Perfectly balanced

In order to achieve perfect even on difficult terrain, the Fendt Cutter drum mowers’ swivel headstock to swing +/- 5° from side-to-side. The spring relief or the oscillating front linkage of the Fendt Vario tractors guarantees low ground pressure. Combined with the front linkage control of the Fendt Vario tractors, this gives you unparalleled ground following and sward protection. The automatic hub centring provides additional safety on the roads.

Best access

In order to perform maintenance, cleaning and a knife change quickly, special attention has been paid to accessibility throughout the machine. All guards open wide at the top and remain secure there thanks to the gas springs. Knives are changed in seconds using a practical special tool. The optional hydraulically opened side guards enable you to switch fields easily without having to climb out.

Fendt Cutter Rear Mounting

On the Fendt Cutter TL drum mowers with centre mounting for the rear hitch, the patented TurboLift System provides a floating cut, and the ultimate in sward protection and forage quality. Even in damp and wet areas, the forage remains free of dirt.

Fendt Cutter TL: Rear mounting with centre suspension

| Cutter 310 TL | |

| Working width (m) | 3,06 |

| Cutting drums (Number) | 4 |

| Blades per cutting drum (Number) | 3 |

Experience a floating cut.

Steplessly adjustable with TurboLift

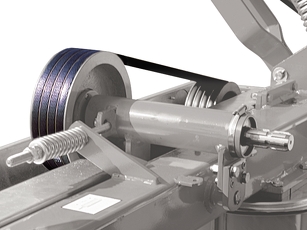

The TurboLift system makes it easy to adjust the desired contact pressure of the mower. In changing operating conditions, you can reduce the contact pressure at any time from the tractor seat and increase it again to the default pressure, all assisted by the well-positioned and easily readable pressure gauge. On headlands, the system always calibrates itself. Alongside perfect forage quality, TurboLift means that little tractive power is required and also means significant fuel savings. The compensation cylinder stabilises the mower unit on headlands and on the roads.

Experience in Hay

A century of silage expertise Tradition, innovation and passion – that’s the recipe for success of the silage centre of expertise in Feucht.