As versatile as your meadows

The Fendt Slicer mowers.

Fendt Early Bird 2026 – Being fast does pay off!

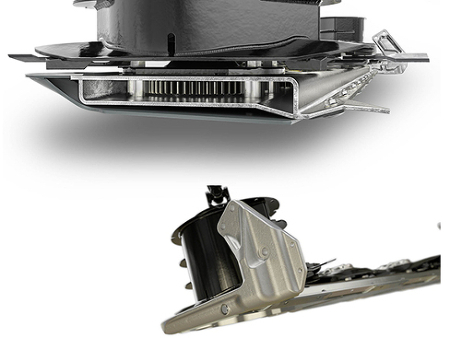

Front mower with alpine oscillating linkage

- Specially developed for alpine use

- Working width: 2.05 - 3.00 m

Front mower with pendulum frame

- The all-rounder among the front mowers

- Working width 3.10 m

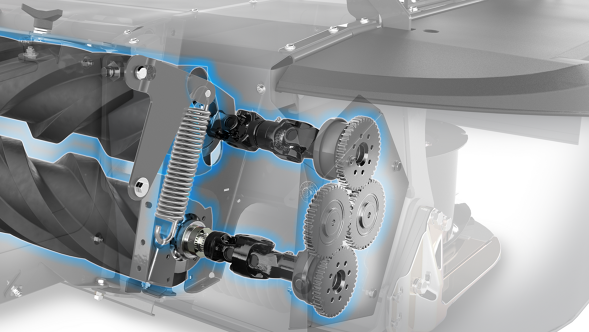

Front mowers with 3D linkage

- Optimal in the mower combination

- Working width: 3.10 - 3.60 m

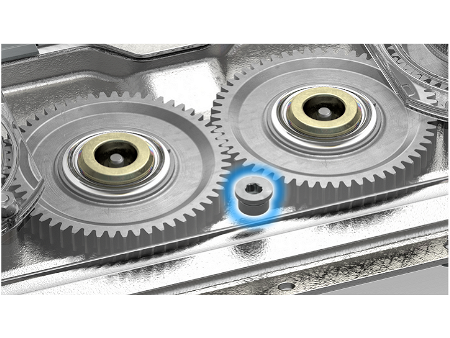

Fendt Streamline cutterbar

Versatile spur gear cutterbar for efficient and gentle mowing

Cut better.

Durable, effective and sustainable

Slicer models with Streamline cutterbar

Working width | Number of cutting discs | |

| Slicer 310 F/F KC/F RC | 3,10 m | 6 |

| Slicer 310 FQ/FQ KC/FQ RC | 3,10 m | 6 |

| Slicer 360 FQ/FQ KC/FQ RC | 3,60 m | 7 |

| Slicer 3160 TLX/LTXKC/TLXRC | 3,10 m | 6 |

| Slicer 3670 TLX/TLXKC/TLXRC | 3,60 m | 7 |

| Slicer 860 KC/RC | 8,30/8,60 m | 2x6 |

| Slicer 960 KC/RC/KCB/RCB (Pro) | 9,30/9,60 m | 2x7 |

| Slicer 1010 KC/RC/KCB/RCB (Pro) | 9,80/10,10 m | 2x7 |

F/FP = Front-mounted oscillating linkage // FQ = Front-mounted 3D drawbar // TL = TurboLift system // X = X transport position // B = Transverse conveyor belt // KC = Tine conditioner // RC = Roller conditioner

The compact angle drive

Traditionally strong.

Every Fendt Slicer disc mower with compact angle drive has multiple overload protections. All models are equipped with either a V-belt drive or a slipping clutch in the drive train and also have an overload protection on each mower unit.

Slicer models with the compact angle drive

Working width | Number of cutting discs | |

| Slicer 210 FKS | 2,05 m | 4 |

| Slicer 260 FK | 2,50 m | 4 |

Slicer 260 FP/FPS | 2,50 m | 4 |

Slicer 310 FPK | 3,00 m | 6 |

| Slicer 270 P | 2,55 m | 5 |

| Slicer 320 P | 3,00 m | 6 |

| Slicer 350 P | 3,50 m | 7 |

| Slicer 4080 TL | 4,00 m | 8 |

| Slicer 4590 TL | 4,50 m | 9 |

| Slicer 313 TKC/TRC | 3,00 m | 6 |

FK = Front-mounted compact linkage // F/FP = Front-mounted oscillating linkage // FPK = Front-mounted oscillating linkage - short // P = Paired direction of rotation // S = Lateral displacement // T = Transport chassis // TL = TurboLift system // KC = Tine conditioner // RC = Roller conditioner

Spur gear drive with small discs

Lightweight and flat design for optimum forage flow.

Slicer models with the small disc spur gear drive

Working width | Number of cutting discs | |

| Slicer 2460 ISL | 2,42 m | 6 |

| Slicer 2870 ISL | 2,82 m | 7 |

ISL = Spur gear drive inner shoeless

Tine rotor conditioner KC

Roller conditioner RC

Gentle processing for legumes and leafy forage

Maximizes output thanks to steel rollers

The robust steel rollers are characterised by a long service life and intensive bending of the stalks for a fast drying process.

Both rollers are directly driven by DUO-Drive for maximum throughput and improved crop flow.

Efficient crop flow and high throughput

Fendt Slicer TurboLift

The floating cut

Relief at all levels

Slicer models with TurboLift cutterbar relief:

Working width | Attachment | |

Slicer 860 KC / RC | 8,30 / 8,60 m | Rear mower combination |

Slicer 960 KC / RC / KCB / RCB (Pro) | 9,30 / 9,60 m | Rear mower combination |

Slicer 1010 KC / RC / KCB / RCB (Pro) | 9,80 / 10,10 m | Rear mower combination |

Slicer 3160 TLX / TLXKC / TLXRC | 3,10 m | Rear attachment |

Slicer 3670 TLX / TLXKC / TLXRC | 3,60 m | Rear attachment |

Slicer 4080 TL | 4,00 m | Rear attachment |

Slicer 4590 TL | 4,50 m | Rear attachment |

Slicer 310 FQ / FQ KC / FQ RC | 3,10 m | Front towing bracket |

Slicer 360 FQ / FQ KC / FQ RC | 3,60 m | Front towing bracket |