The similarity of the front side of Fendt Tigo with a trough has a very specific reason. The operator always has a perfect view in the loading space through the forward sloping body design. With loading capacities of 31 m³ to 41 m³ (DIN) for the PR models, 37 m³ to 42,5 m³ for the VR models and 38 m³ to 54 m³ (DIN) for the XR models, you can transport your crop quickly and efficiently.

Everything under control with Fendt Tigo.

Stay on top of things

Robust and stable:

The Fendt Tigo ensures maximum stability and lifetime. The robust and solid all-steel body with closely-packed side stanchions is directly screwed together with the chassis frame and the profile frame bolted above. This makes it the most stable and the most compact loading wagon of its class.

Simple and without alterations:

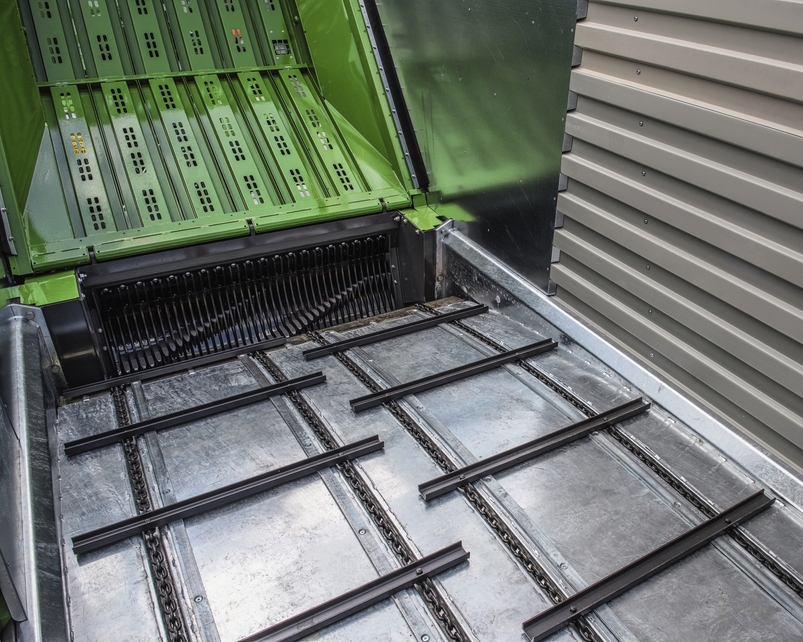

Versatility and maximum operational flexibility are the deciding factors for maximum economic viability. With the Fendt Tigo, you can quickly and easily switch from loading to chipper wagon without any major adjustments. The structure of the forage wagon was designed without tubular frame or tensioning rope, making it ideal for filling with the chopper from above and from the front. At the end of the day, you profit from the low feed losses, high flexibility and fast operational readiness.

The Fendt Tigo leaves nothing to chance.

The right angle

The Fendt Tigo guarantees easy and efficient loading and unloading, without the feed having to be pushed up into a forage channel, as the scraper floor is lowered by 250 mm. The forage wagon precisely sets its power. The perfect arrangement of the conveyor elements means less power is required while loading, which, in turn, means less fuel is consumed.

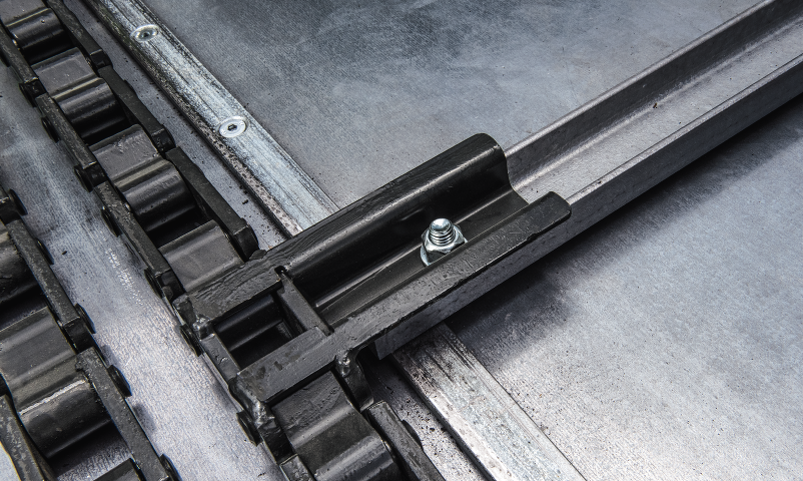

The optimal scraper floor drive:

You can keep calm even in hectic situations with the forage wagon. The hydraulic 2-step scraper floor drive on the XR and VR, optionally even in PR, can be adjusted depending on the crop and weight. The continuously adjustable form feed speed guarantees you the fastest possible emptying. If you are pressed for time, you can engage 'rapid feed' to unload up to a faster and even more efficient 25 m/min. Machines with metering rollers have a scraper floor return as standard. This can also be optionally selected without metering rollers. The reversible scraper floor allows the machine to be loaded from the rear. This means, for example, that square bales can also be loaded by reversing the scraper floor in stages.

The right distribution:

A consistent crop output while unloading improves the performance while compacting in the silo. You can create a uniform blanket of feed on the silo with the high-performance profile of the closed feed rollers. Grass, maize or even whole plant silage are meticulously separated from the feed stock. The Fendt Tigo ensures such a precise unloading process. The powerful spur gear with the large drive chains guarantees a smooth drive. In order to keep the system streamlined, the drive train shafts are enclosed in the frame. The simple design of the rollers towards the rear gives you the flexibility of 2 m³ more loading space.

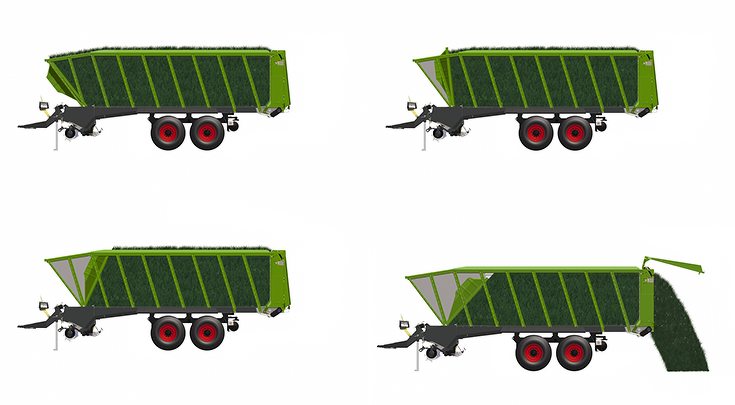

The first component of VarioFill is the bulkhead.

More compact, easier, more manoeuvrable and shorter by at least 1 meter than other loading wagons in its class. With its 80° pivoting multi-functional bulkhead, the Fendt Tigo is one of a kind when it comes to loading. The space above the loading unit creates 6m³ more volume but keeps the vehicle short. The completely closed frame of the bulkhead offers maximum stability in turn. The Fendt Tigo is the payload champion – with its weight-saving and compact dimensions. Combined with the Fendt tractor, it becomes an unbeatable team. Enjoy better road positioning during transport with ideal weight distribution and optimum hitch load.

Second component of VarioFill is the automatic loading.

Always exercise the right pressure with the Fendt Tigo. With the bulkhead acting both as a loading and feeding wall, plus integrated automatic loading and unloading system, every cubic metre of the loading volume is put to best use. Adjust the 2-step automatic loading and continuously adjust the compression pressure of the feed from the terminal. The pre-compacting pressure can be customised optimum to the feed structure with this unique system. Whether it is higher pressure for a maximum loaded wagon or lower pressure to avoid crumbling losses in hay – as soon as the selected compression pressure is reached in the pressure sensor of the hydraulic cylinder, the scraper floor automatically sets itself in motion. If the complete loading space is filled, the bulkhead moves gradually forward. You take maximum advantage of the loadincapacity with the VarioFill and work efficiently and preserving the feed.

Third component of VarioFill is the automatic unloading.

Manual removal of feed residues at the end of the day is not required. The VarioFill makes the unloading a relaxed affair. The unloading process starts with pressing a button. The trunk lid is opened and then the scraper floor and the bulkhead start simultaneously. The multifunctional wall gently pushes the feed stock through the declining movement and reduces the load of the scraper floor chains. The bulkhead presses the last feed wedge actively to the scraper floor through the arching position arising in the end position and ensures that the vehicle is properly emptied.