Our L-Series combines can be equipped with either a FreeFlow or PowerFlow table. Both tables feature a very rugged construction and enable optimum crop feed. The automatic cutting height control and AutoLevel table control reduce the workload, especially when working with large cutting widths. You achieve excellent results, even under difficult harvesting conditions.

Clean work

The FreeFlow table

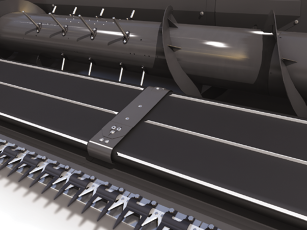

Our FreeFlow table is available in working widths from 4.80 m to 7.60 m. It is especially stable and maintenance-friendly because the components are bolted on. With 1,254 cuts per minute, the high speed of the cutterbar ensures a clean cut with a low power requirement. The intake auger, with a diameter of 610 mm, moves the crop swiftly and uniformly to the crop elevator – ideal conditions for maximum area coverage and the best harvesting results.

The PowerFlow table

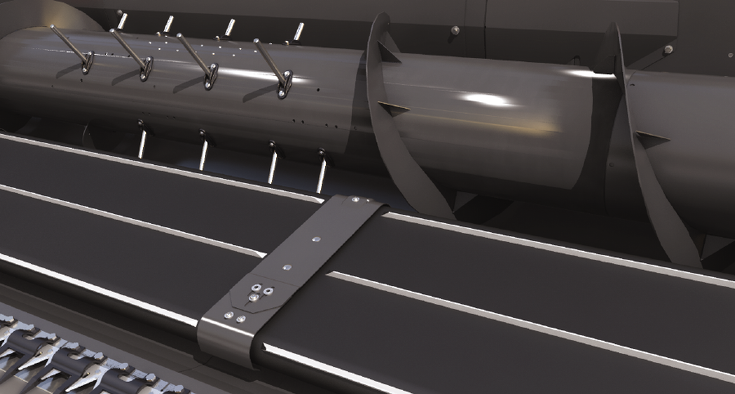

Our PowerFlow table has been known for exceptional productivity for more than 35 years. The big clearance between the cutterbar and the auger facilitates cutting high crops. The PowerFlow belts then transport the crop directly under the auger. This guarantees uniform, heads-first feed for all types of crops and therefore also the best threshing performance as well as an extremely efficient throughput.