The forage drying process is shortened significantly by use of a conditioner. The conditioner helps rub the natural wax layer off the crop and quickly dries out the plants' sap. The light, airy swath also allows intensive air circulation and speeds up the removal of water, gaining valuable time, as you can get on with the rest of the process, and ideally save you time on tedding.

Products & Solutions

Agricultural Machinery

back

to Overview

Tractors

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hp

Fendt 1000 Vario

Fendt 1000 Vario

from 291 kW / 396 hp to 380 kW / 517 hp

Fendt 900 Vario MT

Fendt 900 Vario MT

from 279 kW / 380 hp to 317 kW / 431 hp

Fendt 900 Vario

Fendt 900 Vario

from 217 kW / 296 hp to 305 kW / 415 hp

Fendt 700 Vario Gen7

Fendt 700 Vario Gen7

from 149 KW / 203 hp to 223 kW / 303 hp

Fendt 700 Vario Gen6

Fendt 700 Vario Gen6

from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 600 Vario

Fendt 600 Vario

from 110 kW / 149 hp to 154 kW / 224 hp

Fendt 500 Vario

Fendt 500 Vario

from 91 kW / 124 hp to 120 kW / 163 hp

Fendt 300 Vario

Fendt 300 Vario

from 83 kW / 113 hp to 104 kW / 142 hp

Fendt 200 Vario

Fendt 200 Vario

from 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 VFP Vario

Fendt 200 V/F/P Vario

from 58 kW / 79 hp to 91 kW / 124 hp

Fendt e100 Vario

Fendt e100 V Vario

55 kW / 75 hp

Telehandler

Fendt Cargo T740

Fendt Cargo T740

100 kW / 136 hp

Fendt Cargo T955

Fendt Cargo T955

123 kW / 171 hp

Combines

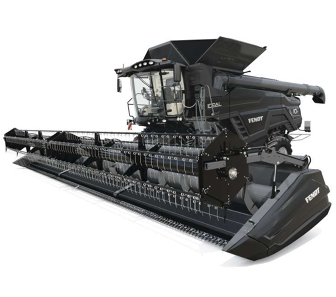

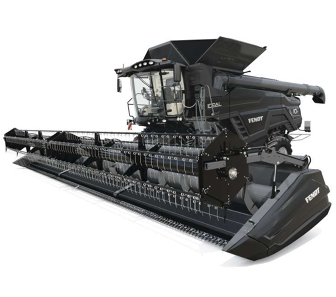

Fendt IDEAL

Fendt IDEAL

from 336 kW / 451 hp to 581 kW / 790 hp

Fendt C-Series

Fendt C-Serie

from 225 kW / 306 hp to 265 kW / 360 hp

Fendt L-Series

Fendt L-Serie

from 192 kW / 260 hp to 225 kW / 306 hp

Fendt CORUS 500

Fendt CORUS 500

from 136 kW / 185 hp to 192 kW / 260 hp

Forage wagons

Fendt Tigo XR/VR/PR

Fendt Tigo

XR/VR/PR

XR/VR/PR

Fendt Tigo MS/MR/MR Profi

Fendt Tigo

MS/MR/MR Profi

MS/MR/MR Profi

Balers

Square Balers

Fendt Square balers

Rotana F

Fendt Rotana F

Rotana V

Fendt Rotana V

Rollector

Fendt Rollector