Fendt Momentum

Information material

Even crops are the key to maximum yield. And it all starts with the planting.

The Fendt MOMENTUM hails a new era in precision planting.

| Momentum 16 | Momentum 24 | |

| Working width (m) | 11.2 | 16.8 |

| Number of rows | 16 | 24 |

| Row spaces (cm) | 70 | 70 |

The Vertical Contouring Toolbar (VCT) compensates height differences of 165 cm. Everything you need for even root development and uniform crops along the working width.

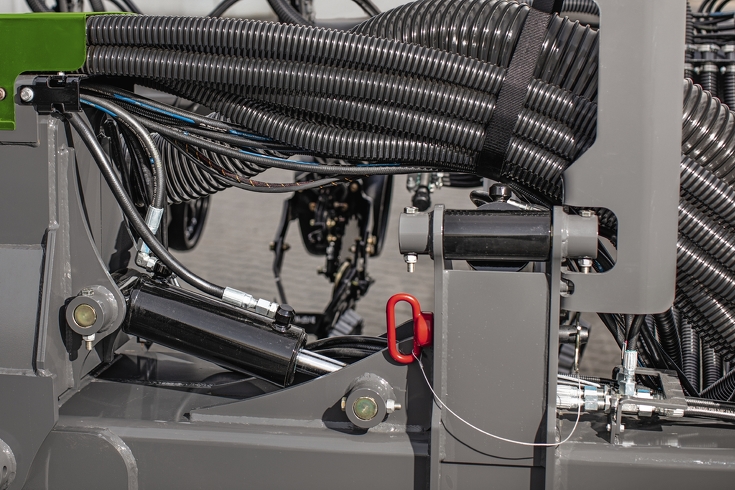

The LoadLogic weight management option also includes a hydraulic weight distribution system. This includes 3 weight management modes: Load Balance, weight centralised over the tandem chassis, and floating position. Load Balance mode evenly distributes the load of the machine across all contact points. Weight centralising mode takes the load off the outer support wheels and the entire weight is carried by the tandem chassis. It also makes sure there is enough support pressure so the in-line ballast weights do not lift up the wings. In floating position mode, the active hydraulic wing ballast is switched off.

The tyre inflation system is part of the LoadLogic weight management system. Various sensors help automatically adjust the tyre pressure.

This is especially true for the seed. We've all asked ourselves, "When's the best time to plant which fields? Is it better to plant early or is it wiser to wait?" Even a couple of days can make the difference to the results of the harvest. Planting too early can lead to losses if the conditions are cold and damp. Planting too late reduces yield as you're not making the most of the potential growth time. The weather is often very unpredictable in the planting season. Rain can delay work by several days. Only powerful technology can maximise on short planting windows.

Losses due to incorrect planting depth are not uncommon. When you drive faster, you need to adjust the tillage disc downforce to avoid reducing the drop depth when the row unit floats. Studies show that if the seed is not planted at the right depth with the right soil moisture, this has a direct influence on the yield.

The Fendt MOMENTUM has two separate seed tanks. The tanks can be easily reached via a platform and come with the option of an active level sensor for monitoring.

This option includes a 3785-litre liquid-fertiliser tank, pumping system, control system to the row units and a vApply module on each row unit. The vApply module controls the output quantity and monitors the flow rate.

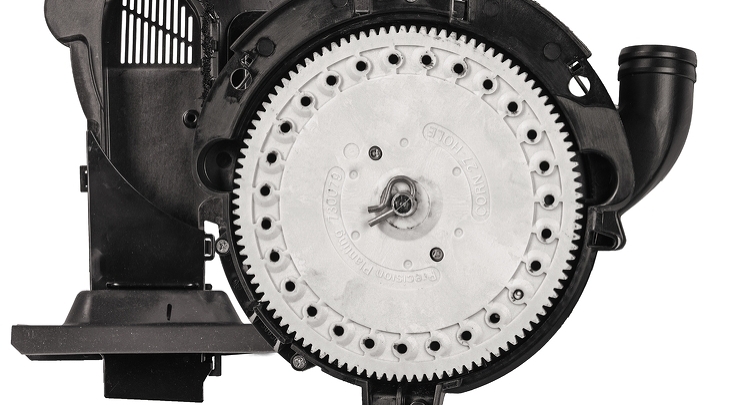

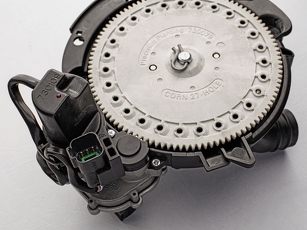

The vSet is easy to use, incredibly accurate and easy to maintain. It has an extremely high singulation accuracy.

The Conceal fertiliser application system is equipped with a single-sided application knife. The application knife is located between the depth control wheel and the double disc coulter. The application point is 7.5 cm beside the furrow at a depth of 2 to 4 cm. As Conceal works directly next to the seed furrow, the application is perfectly placed next to the seed furrow, regardless of the terrain and cornering. A maximum of 270 l/ha can be applied.

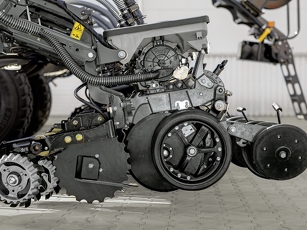

The row unit consists of the metering unit, seed tube, gauge wheels, residue manager, tillage disc and other components. With this modular system, you can select the parts to give you the right solution whatever the conditions.

Creates a specific downforce for each row for the right standing pressure for different soil types and planting conditions.

The row units are electrically driven. The vDrive is marked by its outstanding reliability and precision.

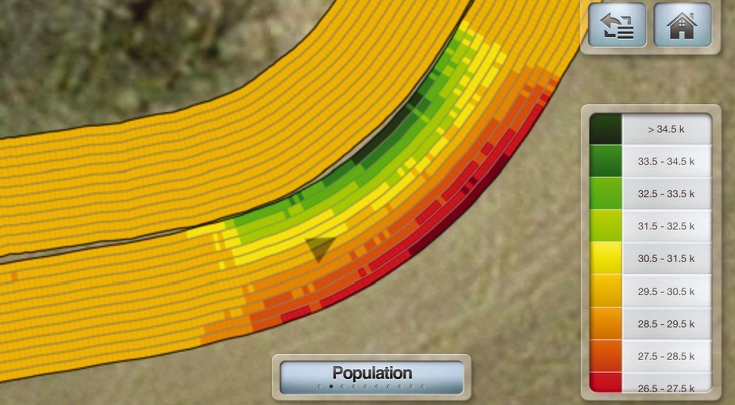

Reduces yield losses due to emergence variations in undulating rows and headlands. Conventional technology below; Fendt MOMENTUM with curve compensation above.

The picture below shows the influence of contours on the ear size when maize planting. Without curve compensation, the inner and outer rows show losses.

Soil types vary widely depending on the region. Various tillage discs are available to suit.

Choose a V-shaped rubber pressure roller or a V-shaped steel pressure roller.

All the general functions – including the LoadLogic weight management system, tyre inflation system, fan control, machine folding/unfolding system and the toolbar lift/lower mechanism – are operated via ISOBUS. You can monitor the level of the seed and fertiliser tank on the ISOBUS screen.

The 20I20 terminal provides the driver with the best possible overview of the current singulation accuracy, vacuum, coulter downforce, planting depth, seed placement, population and liquid fertilisation. If there are any errors, the system helps with troubleshooting. You can set specific alarms and warning parameters so you are notified if thresholds are not met.