Fundamental innovations have found their way into the Fendt 800 Vario, ones that further improve the efficiency of the tractor series. Lively handling up to 60 km/h through greater dynamics, higher torque and improved power availability. At the same time, intelligent solutions, such as the tractor management system TMS, ensure low consumption of both fuel and AdBlue. The VarioGrip tyre pressure regulation system provides efficiency that is transferred directly to the ground.

Superior performance. Perfection in detail.

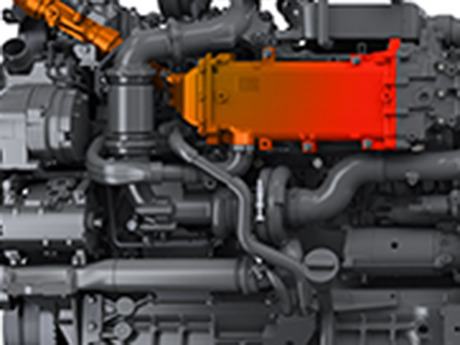

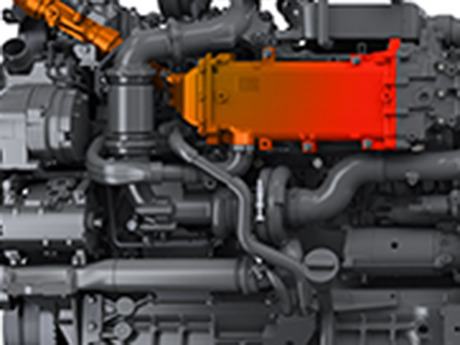

The high-grade solution for extremely low operating costs: the combination of external exhaust gas recirculation (AGRex), passive diesel particulate filter (CSF) and SCR technology.

Environmentally friendly and intelligent

AGRex external exhaust gas recirculation

The external exhaust gas recirculation ensures that the nitrogen oxides NOx are already reduced before they reach the exhaust line. That is more economical, because less AdBlue is required in the exhaust line to further reduce the nitrogen oxides.

AGRex external exhaust gas recirculation

The external exhaust gas recirculation ensures that the nitrogen oxides NOx are already reduced before they reach the exhaust line. That is more economical, because less AdBlue is required in the exhaust line to further reduce the nitrogen oxides.

Diesel particulate filter Coated Soot Filter (CSF)

The passive coated soot filter is regenerated while driving and does not need to be actively started. No additional fuel is required for regeneration.

SCR engine technology

With SCR technology, exhaust is after-treated with Adblue, a 32.5 percent solution of urea, which converts nitrous oxides NOx into non-toxic nitrogen and water.

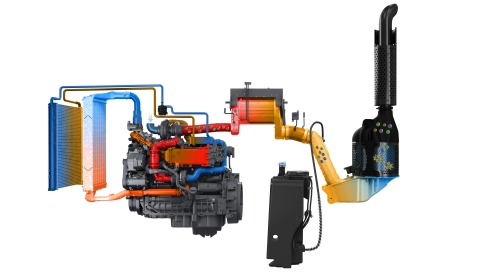

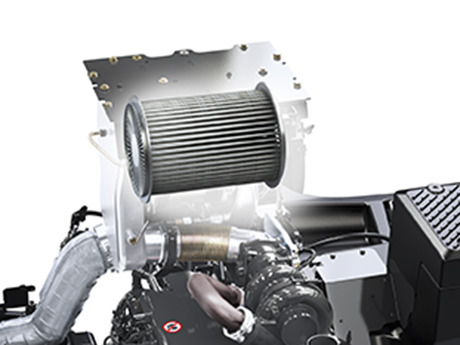

Can do more with twin intercooling

The air that has been pre-compressed in the turbocharger is cooled down by an additional charge-air intercooler, before it is further compressed in the highpressure turbocharger. Thus the engine can take in a larger air mass with the same volume, which also means more oxygen. This results in more efficient fuel combustion and improved performance.

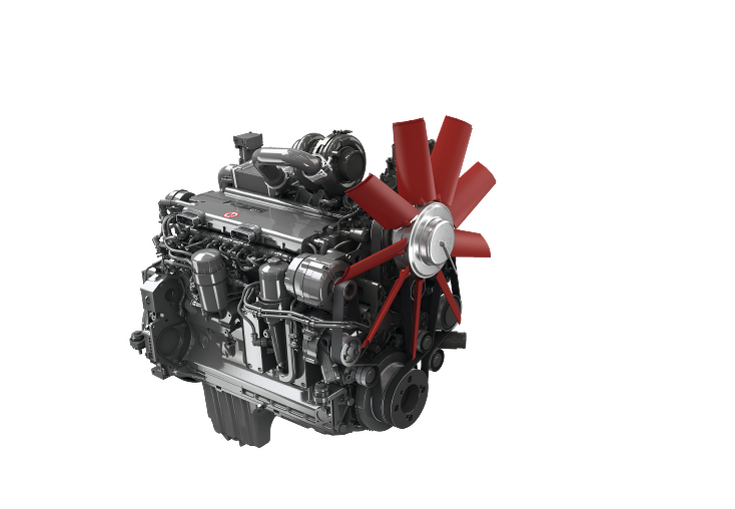

The reversible fan can reverse the air stream automatically – now as a headland management sequence – so the cooler elements are effectively blown clean. What's special: Depending on the cooling requirements, the position of the fan blades is adjusted to increase the cooling efficiency. That saves fuel.

Engine characteristics – Fendt 828 Vario

Through the well-rounded torque curve, more power is already available in the lower speed range. Furthermore, the constant power range provides a broader engine speed band over which the maximum power can be called up. In this range, the rated speed is equivalent to the maximum power.

Steplessly efficient. Fendt Vario transmission.

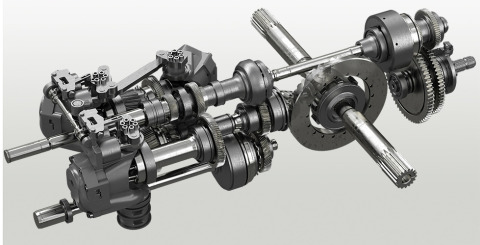

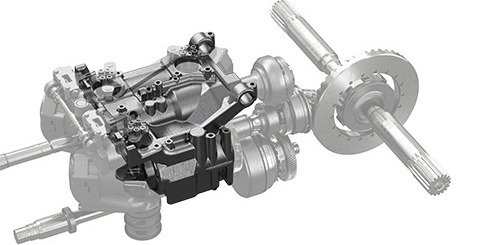

Continuously variable Vario transmission ML 220

For years now, continuously variable transmissions have proven their leading efficiency and performance and have become the first choice. Operators are always in the position to work at the optimal speed, which means considerable savings potential. You save valuable working time in different operations through higher area coverage and also profit from low fuel consumption. With separate transmission and hydraulic oil supplies, means that dirt cannot enter the transmission.

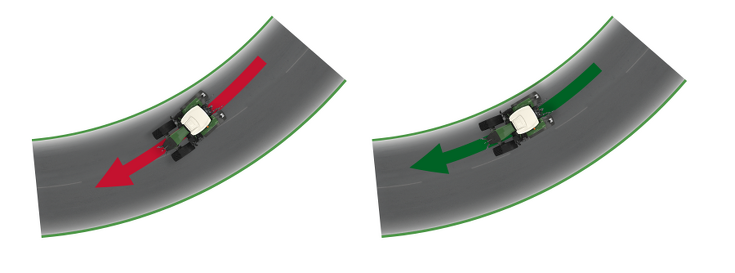

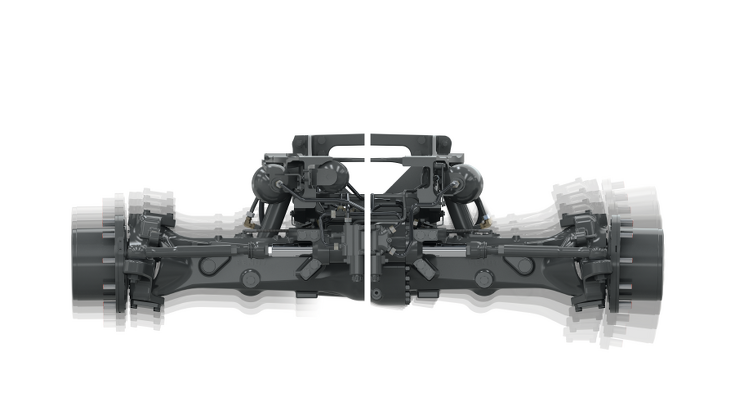

Maximum on-road and in-field driving safety

The chassis guarantees optimum operability on the road and in the field. With the unique Fendt Stability Control FSC you always have a safe feeling when driving, even when negotiating curves. At the same time, the practically maintenance-free braking system, comprising wet disc brakes on the cardan shaft and the rear wheels, increases driving safety. The chassis design provides the best ride comfort as well as optimum ergonomics.

Fendt Stability Control (FSC) provides additional stability and steering precision when driving above 20 km/h on the road. When the driving speed drops below 15 km/h, compensation between the left and right side is possible again, which guarantees the best ground contact.

Pulling power through self-levelling front axle suspension

The coordination of the front axle suspension of the Fendt 800 Vario has been optimised for heavy draft operations. This enables a 7% higher transfer of traction than an axle without suspension, since the wheels adapt themselves ideally to the ground, which prevents inefficient power-hopping.

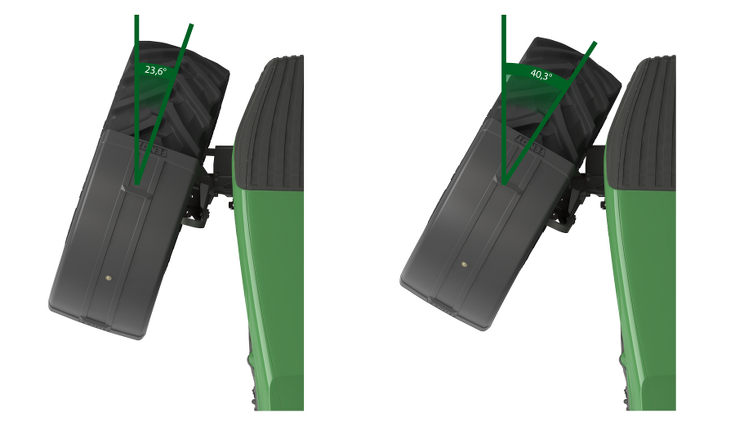

The Fendt 800 Vario has a self-levelling front axle suspension as standard. It has a120-mm suspension travel, plenty to level uneven surfaces. The +/- 8° swing angle ensures stability while driving. The 50° maximum steering angle on the front axle guarantees maximum manoeuvrability. The entire suspension travel can be run through manually when standing still, e.g. for picking up a front weight without front linkage.

In relation to the standard setting, with VarioActive one only needs approx. 60% fewer turns of the steering wheel for the same wheel angle. With VarioActive, you profit through the faster reaction of the steering during tight turning manoeuvres at the headlands. For reasons of safety, it can only be used from 0 – 25 km/h.