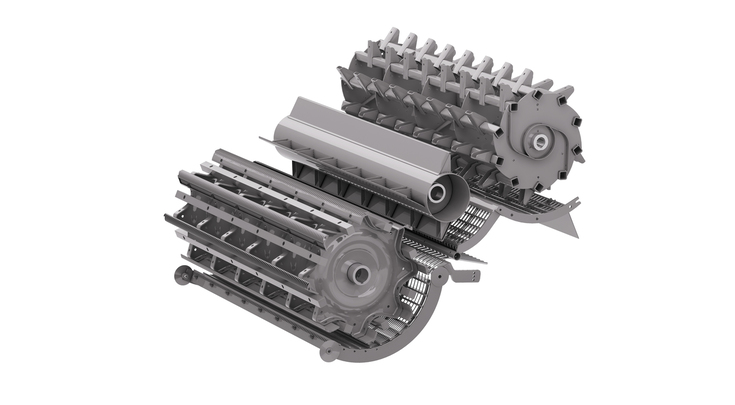

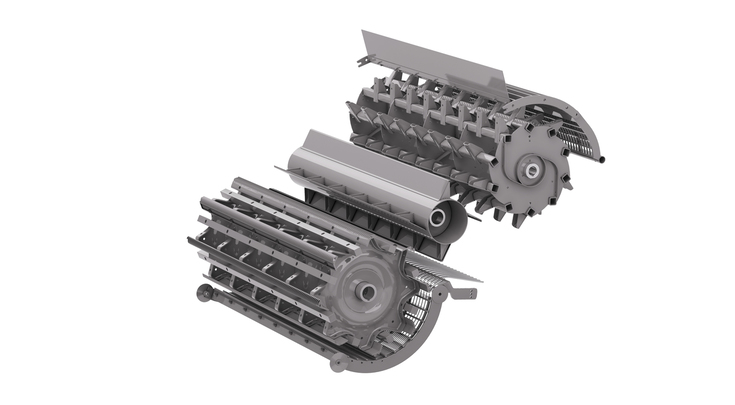

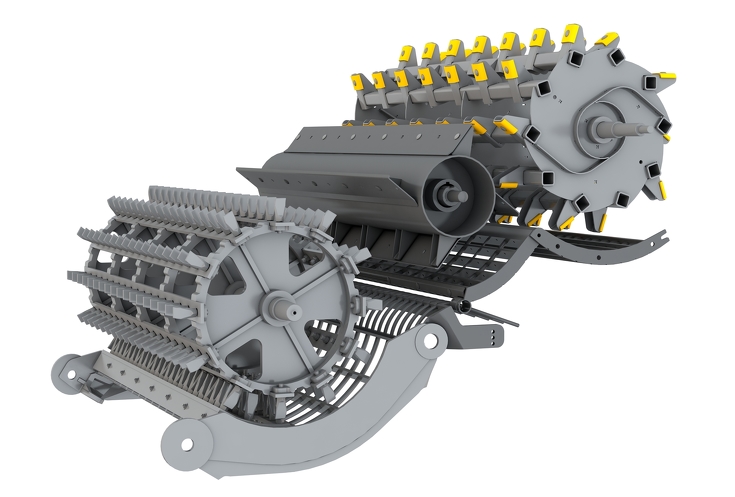

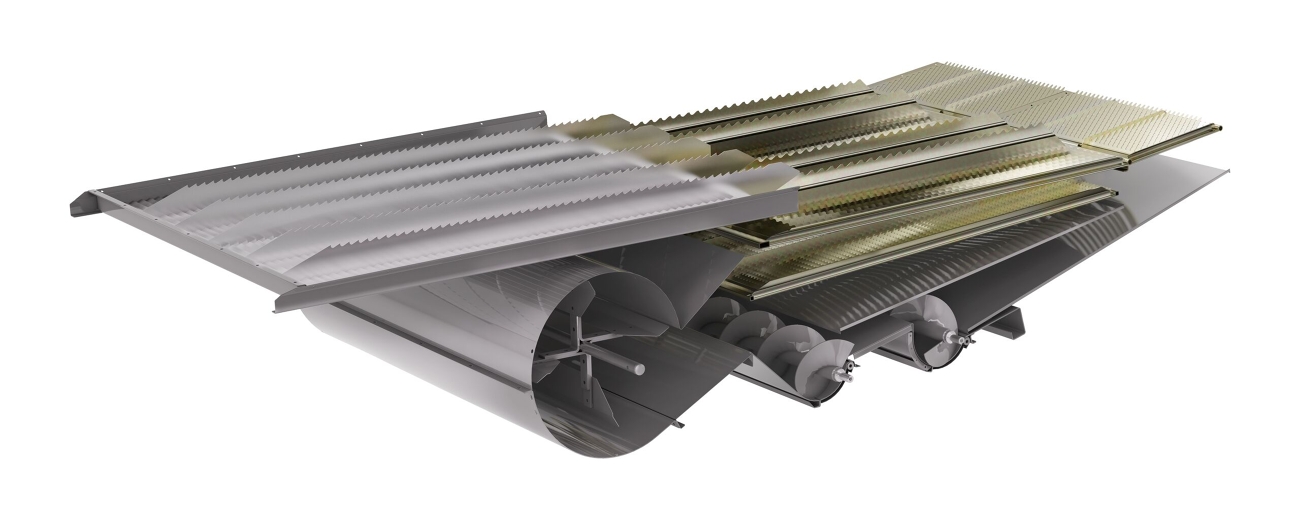

The high capacity of the threshing cylinder on our L-series is a consequence of its large 600-mm diameter. The result is perfect threshing with a clean sample and less broken grain. The high inertia threshing drum runs very smoothly, even under difficult harvesting conditions. It is very gentle in handling both the grain and straw.

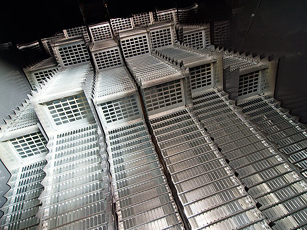

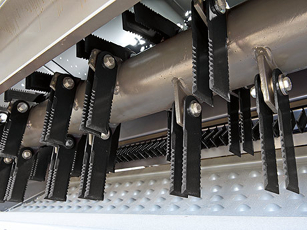

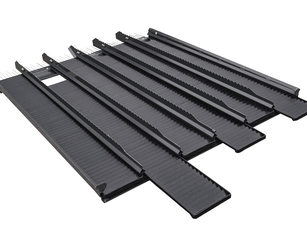

Smart concave:

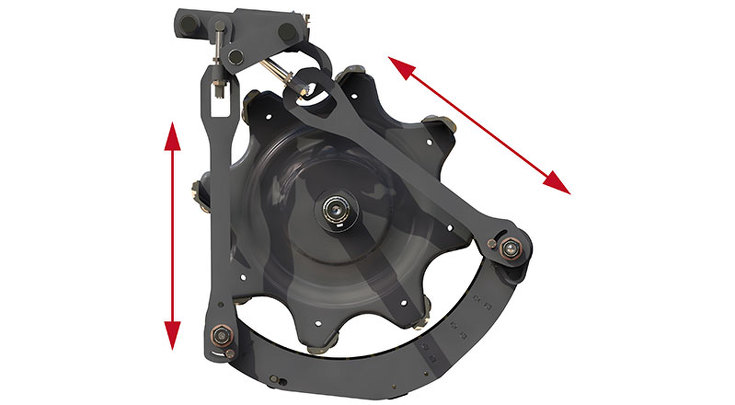

The concave features different wire spacing. The clearance in the back section of the concave is twice as big as in the front area. This arrangement ensures the optimal ratio between good threshing capacity and high separation capacity. To optimise the threshing quality, you can adjust the concave independently at the front and back from the comfort of the cab.