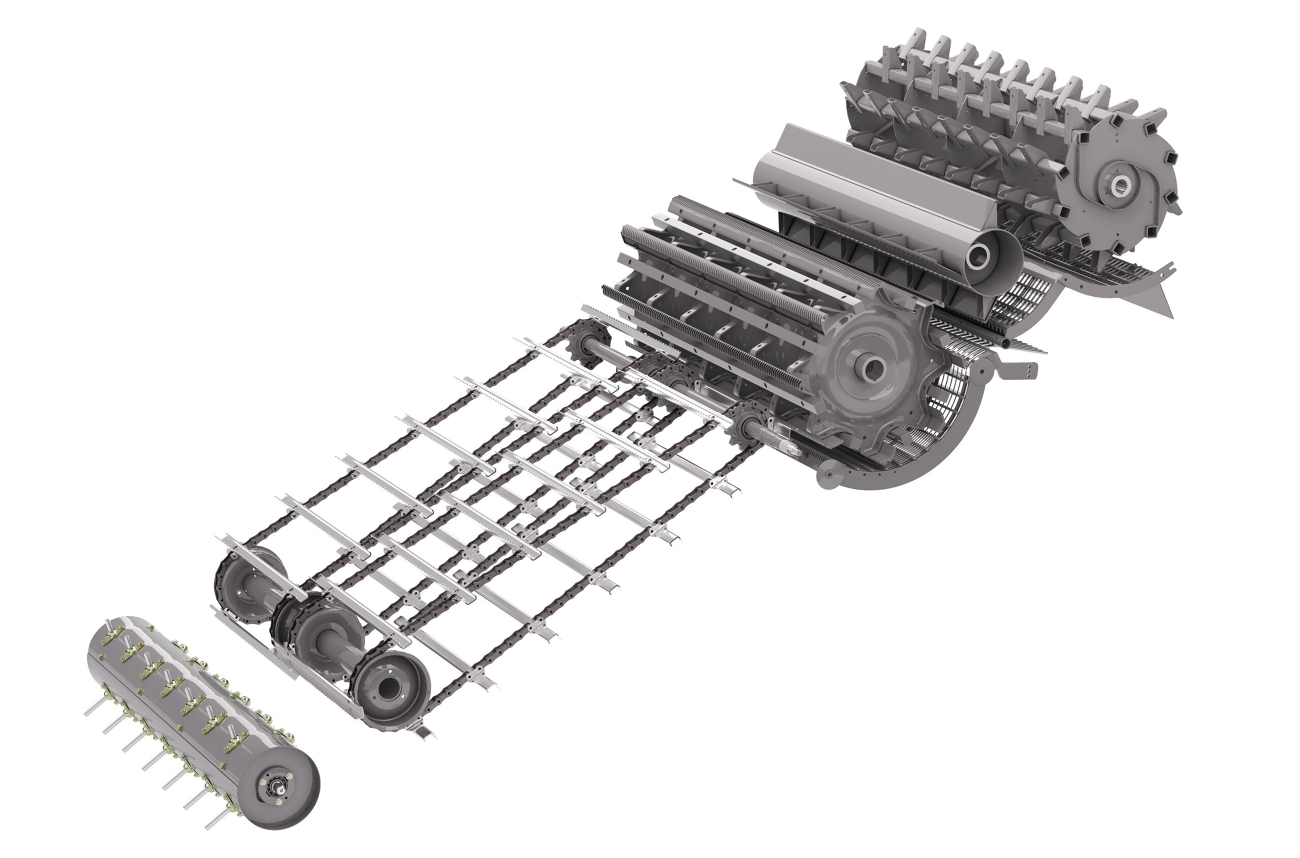

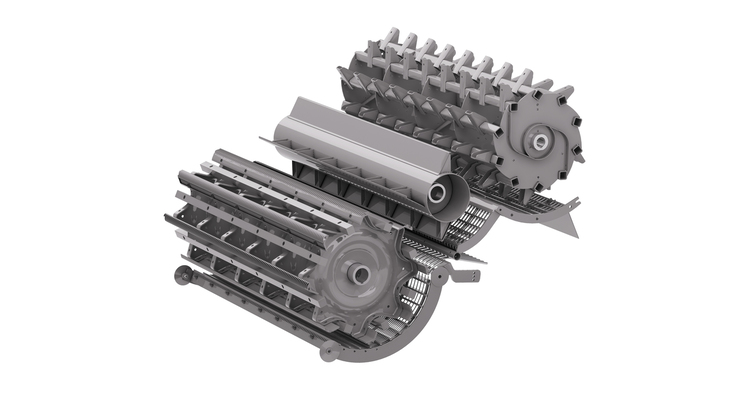

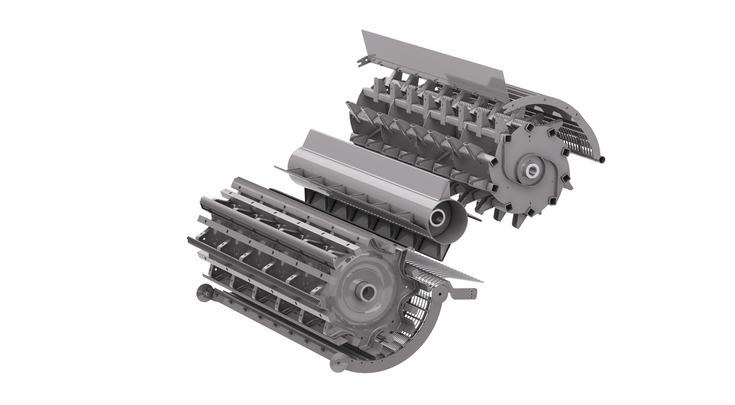

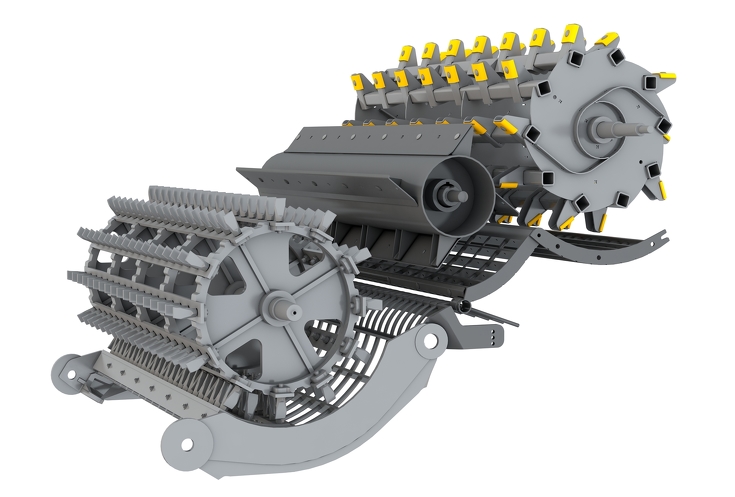

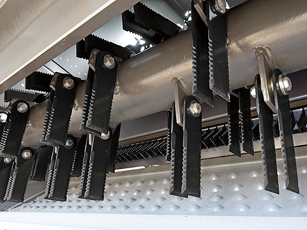

In the standard version, the ABC (Active Beater Concave) module, which is an extension of the concave on the beater, really shows its strengths. This module enhances the separation performance and the straw is fed directly and very uniformly onto the straw walkers.

Extras in the MCS Plus version

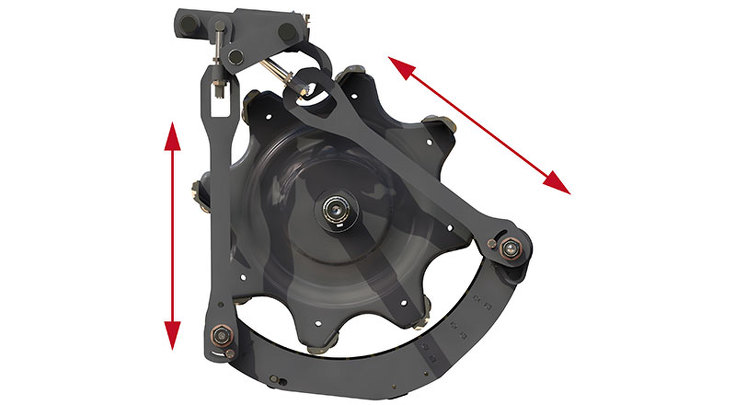

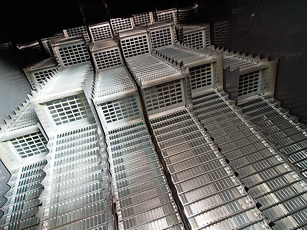

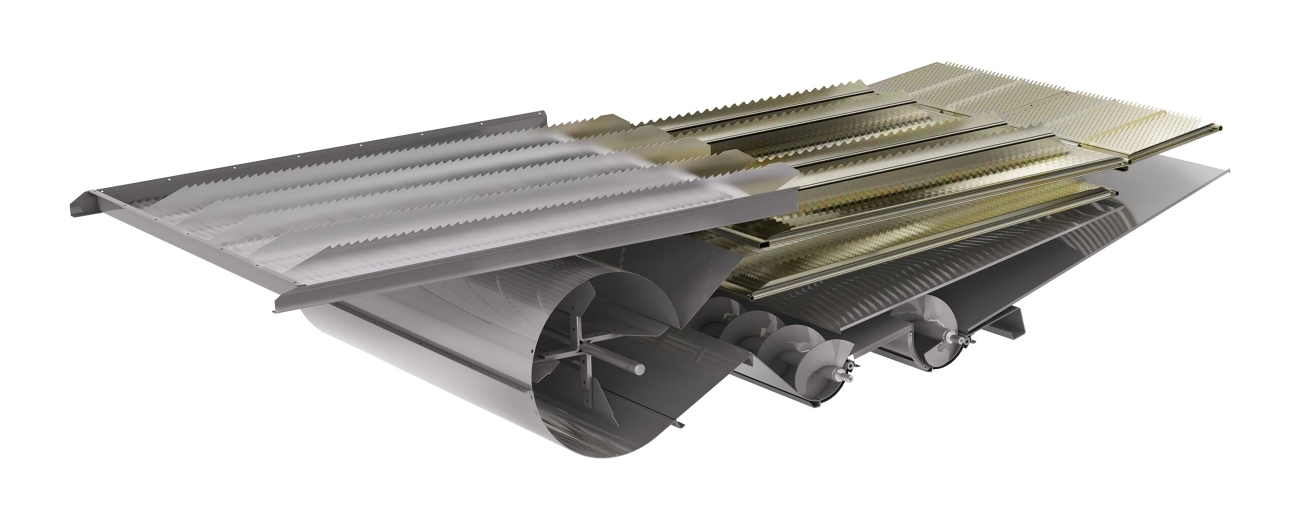

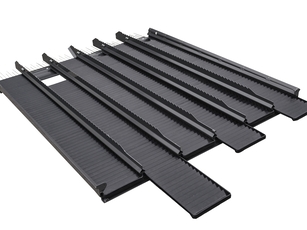

In this variant, the L-Series combines are equipped with the Power Feed Roller (PFR) and Multi Crop Separator Plus (MCS Plus). The PFR ensures optimal crop flow from the cutter unit to the feed channel. It is attached directly to the crop elevator. Rotating at a speed of 267 rpm, it picks up any crop over the full width of the intake. The MCS Plus separating concave has an enormous separating area. As much grain as possible is separated out before the crop even reaches the straw walkers. What is also special about our MCS Plus combines is that the separator concave can be swung up over the rotary separator. An electric motor brings the concave into the desired position as need; tools are not required.

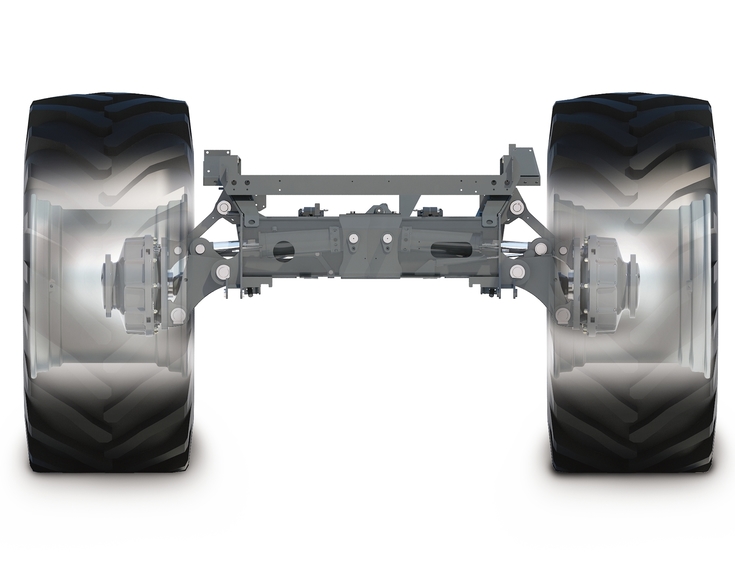

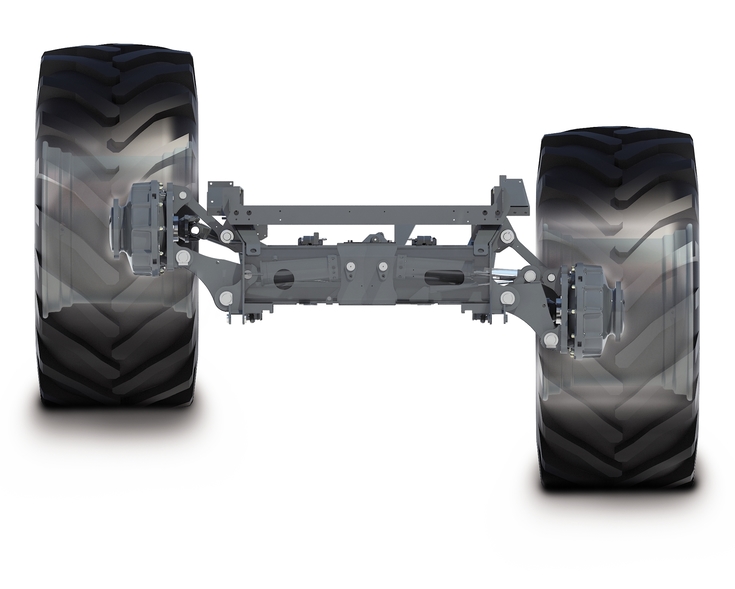

Intelligent slope compensation.

Optimum in-field and on-road characteristics

Besides the classic advantages of a chassis levelling system, the ParaLevel system offers additional benefits, like switching between work and transport mode. Work mode gives you greater stability and safety on slopes, because the outer width is increased. In transport mode on the other hand, the front axle is lowered and the outer width is reduced. With an outer width of 3.50 metres, both combine models – 5255 L PL* and Fendt 6275 L PL** – comply with traffic regulations.

* 5 straw walkers with 800/65 R32

** 6 straw walkers with 650/75 R32