Communication between tractor and implement

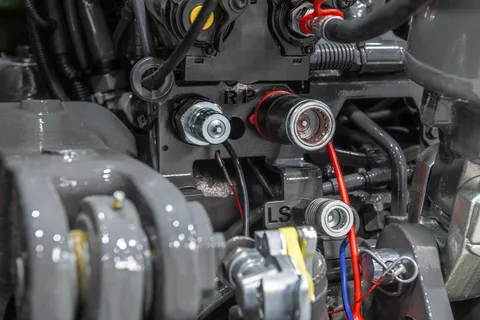

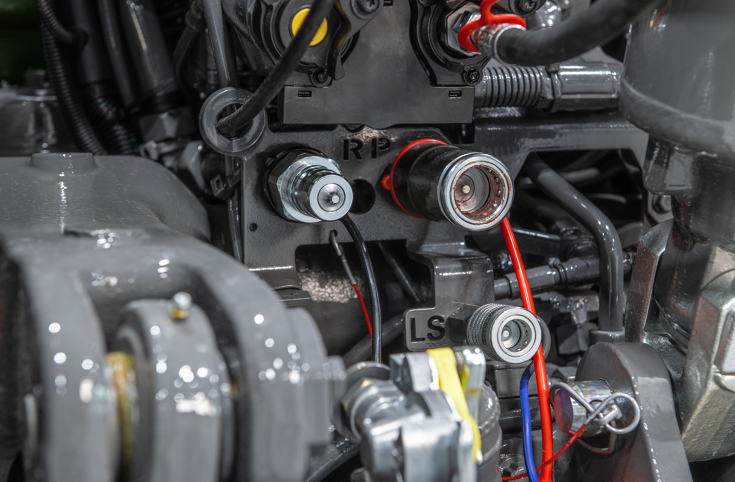

Tractors in combination with implements that have a high oil requirement for their hydraulic functions, such as complex potato harvesters, are supplied via the Power Beyond connection and the hydraulic Load Sensing (LS) connection is controlled. Both connections have remained unchanged in agriculture for 30 years.

Certain Fendt tractors and the ROPA Keiler II RK22 potato harvesters already use electronic LS (e-LS) components within the implement to optimise the system. The required oil pressure is transmitted electronically to the control unit, which then adjusts the pump accordingly. With the tractor and implement working together, the communication of the oil pressure required by the implement continues to be carried out hydraulically via the LS control cable. The electronic signals are therefore currently converted back into hydraulic signals both in the tractor and in the implement. The use of hydraulic and electronic components requires more components than with purely electronic control and is therefore more susceptible to errors. If there are inaccuracies in the conversion of the signals, the tractor can also provide the wrong oil pressure. The system may also oscillate as a result of the corrections that are then necessary. It may also happen that the driver still has to adjust the control pressure difference manually or it is permanently increased. The machines are therefore less efficient, dynamic, stable and inexpensive, as they could be with purely electronic signal transmission.

“e-LS connect” for purely electronic signal transmission

In the future, Fendt and ROPA will be the first manufacturer to offer purely electronic communication of the required oil pressure for tractors and implements via “e-LS connect”. If the driver wants to operate a certain function of the potato harvester, the required oil pressure is transmitted electronically to the tractor's control unit via ISOBUS. The electronic signal controls the pump in the tractor and provides the pressure for the right volume flow, based on demand and precision. This is crucial, for example, for functions such as controlling the steering or telescopic axis, depth control of the attachment or operating various bunker functions. This shows the advantages of e-LS connect in a more dynamic and agile response, which, for example, is better maintained by the harvested quality of the potato when filling boxes. At the same time, the system is more stable overall. By using e-LS connect, components such as the pressure regulator valve, pressure sensors, the LS line and the LS connection are also superfluous. Since the standard pressure difference is always set correctly, diesel consumption decreases and at the same time potatoes with higher quality are harvested, because the harvester, for example, picks up the ridges even more precisely. Other advantages include greater operational reliability through fewer used components and, as a result, higher productivity. The elimination of the coupling of LS control cables prevents dirt from entering the system and protects the environment by preventing oil leakage losses.

From June 2026, existing tractors can be retrofitted with corresponding components via software updates. These include the series:

- Fendt 500 Vario Gen4

- Fendt 600 Vario

- Fendt 700 Vario Gen7

- Fendt 700 Vario Gen7.1

- Fendt 800 Vario Gen5