A diesel engine is no longer a must in agricultural machinery such as tractors, loaders or similar vehicles. On the contrary - many manufacturers are already focussing on new innovative concepts in some areas, e.g. with electrically powered engines. Fendt, for example, presented the fully battery-electric Fendt e100 V Vario narrow-track tractor at Agritechnica 2023 in Hanover, the world's largest agricultural machinery trade fair. The LandBauTechnik Bundesverband e.V. took this as an opportunity to complete the successful auditing of the Fendt Training Center Süd in Altdorf as a recognised training centre for high-voltage specialists and to present the award at the trade fair.

New types of engines that work with high-voltage power present workshops with a new challenge, as the safety of employees must be guaranteed. "According to DGUV Information 209-093, workshops that work with electrically powered, i.e. high-voltage vehicles and systems, must comply with certain safety regulations. This includes the appointment of a so-called high-voltage expert by the company. This person is authorised to carry out work in a managerial, supervisory or executive capacity on high-voltage components safely and in accordance with the regulations. For this reason, we have designed a training course with a high quality standard that is specifically geared towards the needs of LandBauTechnik," explains Dr Michael Oelck, Managing Director of the LandBauTechnik Bundesverband e.V.

"Our research and development team at Fendt is already working on various alternatives to the combustion engine. With our Fendt e100 V Vario, we have presented the first series production-ready electric tractor. In this training programme, employees from sales partners and the service department learn how to work expertly and safely with an electric engine in the range of up to 1,000 volts alternating current (AC) or up to 1,500 volts direct current (DC). This means that farmers can rely on their machine and the corresponding service," says Uwe Vögler, Manager Aftersales Training Western Europe at Fendt, explaining the decision to be audited.

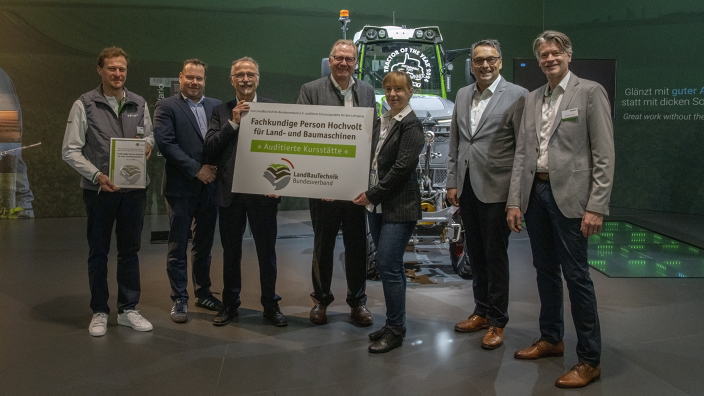

An audit of the training centre and the other requirements had previously been carried out, and now Managing Director Dr Michael Oelck also presented the corresponding certificate and congratulated Rainer Kleinhans, Uwe Vögler, Roland Schmidt and Burkhard Krapohl.

In order to be allowed to carry out maintenance, repair, overhaul and troubleshooting on the HV systems as an authorised service partner, employees in the workshops must also complete advanced training from the machine manufacturer: The respective manufacturer's specifications for work on HV components are binding.

Fendt is now part of a nationwide network of 27 audited training centres for the training of high-voltage specialists in Germany.

Further information and training dates can be found at WWW.LANDBAUTECHNIK.DE/HOCHVOLT