Smart Farming modules - individually selectable

Guidance with FendtONE.

For guidance applications in agriculture, the machine is equipped with a satellite receiver. Once the receiver has a clear view of at least three satellites, the position can be determined. Due to several interrupting factors, such as orbit errors, weather-related influences, as well as absorption and reflection in the atmosphere, GNSS (GPS) position data alone can lead to deviations of up to +/- 12 metres – too inaccurate for agricultural use. For standard applications in agriculture, such as tillage, the DGPS correction method can increase the positional accuracy of a GPS receiver to +/- 15 to 30 centimetres.

Agronomy with FendtONE.

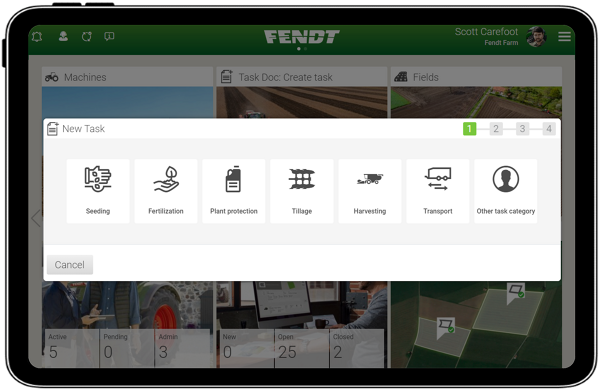

Fendt offers a task-based documentation system that enables the exchange of field and task data, as well as task reports between the Fendt fleet and FendtONE offboard* or a farm management information system (FMIS). Tasks can be conveniently created in FendtONE offboard* or another FMIS and transferred to the tractor. The task serves as the basis for the field work, with all the necessary field data and information about the planned work. During field work, data from the team is recorded and, once the work is complete, it can be sent back to the FMIS as a task report for documentation purposes. Data can be exchanged via USB stick or conveniently wirelessly in standardised data formats. Data relevant to track guidance, such as field boundaries and waylines, can also be transferred to the entire fleet using the complete data export and import function.

*Please note that FendtONE offboard is not currently available in all countries.

*Please note that FendtONE offboard is not currently available in all countries.

Telemetry with FendtONE

Keeping an eye on the entire fleet or checking the diesel level of a specific tractor – telemetry makes it possible. Detailed machine data in real time is not only advantageous for you, it also enables your service partner to make the best possible diagnosis if something should go wrong. Discover our telemetry solutions and see for yourself how they can help you make better logistics and service decisions.

Machine control with FendtONE.

Only when the tractor and implement can communicate with each other can the full potential of the combination be utilised. It makes your work as effortless as it can be.

ISOBUS is the standardised system for data transmission between tractor and implement

- Fendt Section Control: Automatic section control to avoid overlapping

- Fendt Variable Rate Control: Maximum area yield through site-specific operation

- Option to automatically control certain tractor functions using the Fendt Implement Management (TIM) implement