Alternative drives and autonomous work

In the area of alternative drives, Fendt presented the battery-electric tractor Fendt e107 V Vario as early as 2023 and the standard tractor, Fendt e107 Vario, in 2024. Both models achieve 50 kW (68 hp) in Eco mode and up to 66 kW (90 hp) for a short time in Dynamic+ mode. At Agritechnica 2025, the Fendt e100 Vario will be shown in combination with a battery-electric range extender from GreenIng, mounted on the front linkage and a precision seed drill on the rear using the relay cropping process.

The use of relay cropping has a positive effect on soil health. In addition, a row and lane detection system (local guidance system) will be presented on this machine. This is a system that operates independently of GNSS (Global Navigation Satellite System). The advantage of local navigation systems is that they can use environment sensors to follow contours in the field or the plantation precisely and dynamically without knowing the exact course of a lane, a swath or a series of plants in advance. The system thus complements satellite-based guidance systems and marks a further step in high-precision area processing.

The focus of the presentation is on an energetically self-sufficient and precisely working team. While the range extender ensures extended operating times for battery-electric tractors with additional electrical storage capacity and can be charged with energy produced during operation, the combination works in conjunction with sensor-based technology for environment detection in different crops independently of satellite connections.

Fendt 800 Vario - Autonomously controlled

With technologies such as Fendt VarioDrive, a new cab with a new lighting concept and options for installing sensors such as the Tech Rails and numerous smart farming options such as the new Fendt Workgroup function, Tramline Control or TIM, the new Fendt 800 Vario is already designed for numerous future requirements for a higher degree of automation. In the Fendt Future Zone, the Fendt 800 Vario will be presented with the OutRun retrofit kit for autonomous driving from PTx Trimble. With this system, the Fendt 800 Vario can act autonomously in harvesting with a chaser bin, or with the OutRun Tillage Kit autonomously carry out soil cultivation even after harvesting.

At the same time, features such as the CORE80 engine including the Fendt iD low-speed concept, the Fendt VarioGrip tyre pressure regulation system and optional flat face couplings in the rear ensure particularly sustainable and soil-friendly work with the Fendt 800 Vario. The CORE80 engine is already approved for HVO100 and other fuels according to DIN 15940. Operating with HVO can significantly reduce the machine's CO2 footprint. Fendt VarioGrip ensures high soil protection. Fendt VarioGrip is optionally available directly from the factory for both the flange and the stub axles, for dual tyres and also with wheel weights.

More about FENDT 800 VARIO

More about FENDTONE

Autonomous control of a grain cart

With the OutRun retrofit kit, PTx Trimble has developed a solution for the cooperation between combine harvesters and grain carts. Especially during the hectic harvest season, the demand for workers is high, with OutRun certain tasks can be carried out autonomously, so that the skilled workers can take on other tasks. The PTx Trimble retrofit kit with obstacle detection sensors is installed on the tractor. The driver of the combine can request the chaser bin via tablet from the combine harvester if necessary. With the help of intelligent route planning, the team autonomously finds its way to the combine harvester and then drives parallel to the combine harvester for it to unload the grain. Once the process has been completed, the tractor is sent back to the edge of the field at the push of a button with a grain cart and can, for example, transfer the crop to a truck for road transport. From 2026, this solution is available on the North American market for the Fendt 900 and 1000 Vario series. From the end of 2026, the expansion of the functionality for autonomous soil cultivation is also planned.

More about OutRun

Fendt & PTx Trimble RowPilot - Hoeing supported by artificial intelligence

Technology for mechanical weed control has been increasingly in demand for several years, not only in organic farming, but also in conventional farms. In addition to societal demands for more environmentally friendly measures and the ambitious goals of the EU Green Deal, increasing resistance and loss of active ingredients are also triggered.

Drivers perform numerous tasks in the field, so machines such as hoes must be simple, so that even inexperienced drivers can carry out the work safely and precisely on long days. This is especially true for hoeing with a lateral-shift frame. Technologies supported by cameras and artificial intelligence (AI) can help here.

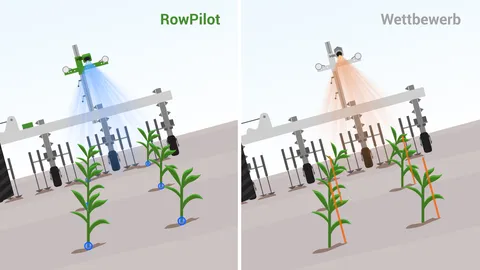

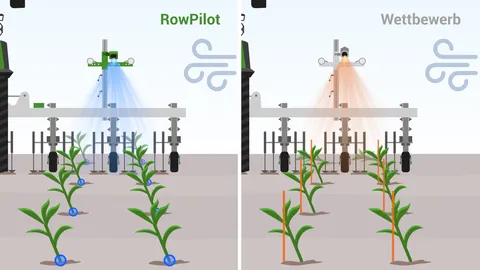

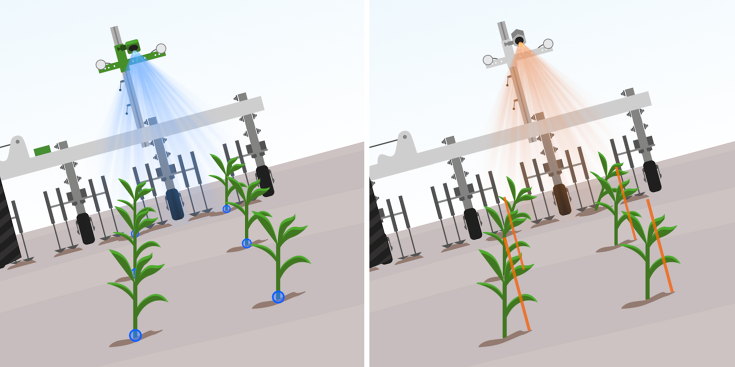

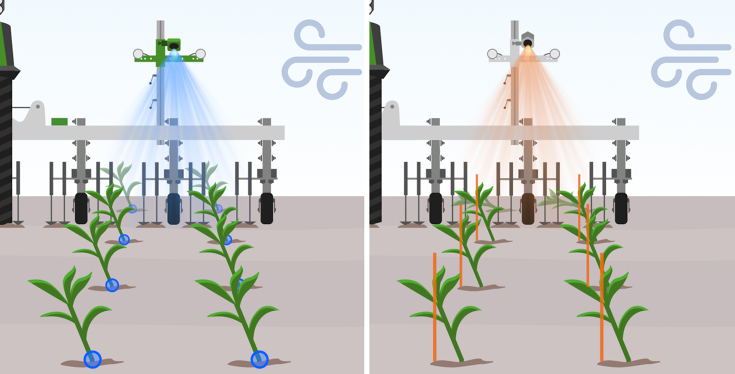

Until now, camera-supported systems have been working precisely when plants, soil and weeds are clearly distinguishable and the rows are clearly visible. Factors such as crosswinds or slope travel can tilt askew, and conventional row recognition is reaching its limits. Similarly, inhomogeneous stocks in the field make it difficult to recognise rows, whether through weeds, missing plants or different growth stages.

Fendt and PTx Trimble have jointly developed the RowPilot to meet these challenges. The RowPilot is an AI-based row management system for mechanical hoeing devices with a focus on simple, reliable operation. AI-based systems meet proven standards such as ISOBUS to achieve high precision with maximum compatibility.

The decisive difference to conventional systems is that artificial intelligence does not recognise the rows on the basis of their leaf mass, but at the exit point of the plants at the soil level. This is particularly important when working on the side slope and wind and thus leads to particularly high robustness and precision. The drift of the hoe on the slope is additionally compensated by a position sensor.

In contrast to conventional systems, AI relies not only on the colour of the crops, but also on its geometric properties. The RowPilot achieves a reliable work result even with dense weed and inhomogeneous crops.

Simple handling

The comprehensive training data of the AI significantly facilitate the application of the RowPilot. Drivers set the position of the camera and the row spacing on the terminal. Information on the height, width or colour of the crop is therefore obsolete. This also allows a quick change between different crops. The system is fully integrated into the ISOBUS of the hoe. Functions such as individual row lift can also be carried out easily and automatically via Section Control or controlling the lateral-shift frame.