Manual engine speed control for Fendt Katana 850

Until now, drivers of the Fendt Katana could choose between the “Eco” and “Power” driving modes. In power mode, the full engine speed is available. If the full power of the forage harvester is not required, it saves fuel in eco mode. The speed of the chopping cylinder is kept high while the engine speed is reduced. The software of the Fendt Katana 850 model has been further developed to allow small step-wise control of the engine speed in seven steps to further reduce fuel consumption. Drivers can choose between 1,600 rpm and 1,900 rpm in 50 rpm increments. Four different torque curves are stored in the machine, each optimally designed for the selected engine speed. For all curves, the engine speed increases rapidly when changing to the next higher step, and decreases slowly when changing down. This way, the machine always remains at its optimal operation even when the speed is changed. Drivers can react specifically to different crops as well as harvesting conditions by adjusting the engine speed. This saves fuel, especially in partial-load operation.

pro instead of plus – New solutions

Until now, Kemper headers from 360plus to 490plus with working widths of up to nine metres were available for the Fendt Katana 650 and 850 models. From Agritechnica 2023, the new generation pro maize headers from Kemper will be available instead. These are characterised by lower cob and harvest losses, higher performance in stocks and optimised crop flow, especially in difficult harvesting conditions. These innovations increase feed quality and have a positive effect on animal health. An optional third probe runner for the 375pro and 475pro models optimises header height control. On the 390pro and 490pro models, the third skid is standard equipment. This option, just like the automatic row guidance, is available for the Fendt Katana 650 and 850.

Improved yield measurement through NIR sensor

Since 2022, Fendt has been recommending the NIR sensor from IT Photonics for the Fendt Katana. The NIR sensor records the exact contents of the harvested crop. In combination with the NIR sensor, the Fendt Katana can now also perform a continuous correction yield measurement. If the NIR sensor is activated, it continuously records the dry matter of the crop and corrects the fresh matter yield based on the recorded dry matter. This means that the yield measurement no longer needs to be calibrated so frequently. This simplifies the operation for the driver and increases the accuracy of the yield measurement even under variable harvesting conditions.

Extended wear package

The Heavy Duty (HD) wear package for the Fendt Katana has been optimised and now also includes the section behind the accelerator and discharge chute.

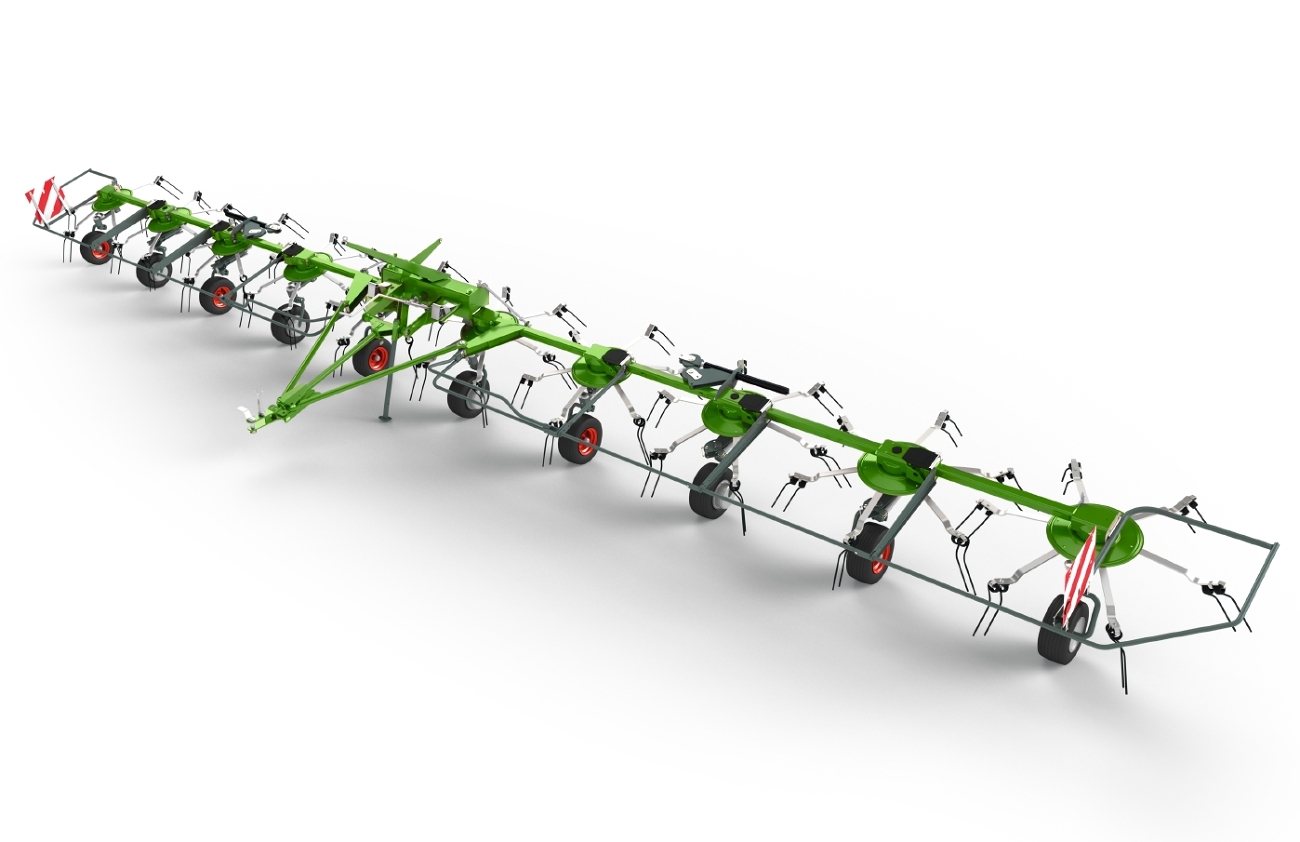

Expansion of the Fendt Twister product range

The Fendt Twister rotor tedders are characterised by innovative and sophisticated technology for fast drying of green forage. The existing product range is expanded by the Fendt Twister 1100 and Fendt Twister 1300 Hydro series. This series has been specially developed for largerfarms that rely on machine performance. The tedders have a working width of 10.20 metres with eight rotors to 12.70 metres with ten rotors. The Fendt Twister Hydro is characterised by its large working width with low power requirement, as well as optimum weight distribution and durable components.

The tedder can be hitched directly to either the tractor's implement rail, drawbar or hitch. The working height is adjusted centrally via a crank. Thanks to the large-volume balloon tyres and specially centred caster wheels, the machine runs extremely smoothly. For work at the edge of the field, the Fendt Twister Hydro comes with an edge spreading device as standard. The entire rotor unit is tilted and the crop is thrown to the centre. This also allows crop from shady fringe areas to be dried and, in the case of layer line work, the material can be scattered upwards. This reduces feed losses. For a high level of operating comfort and maximum flexibility, the hydraulics ensure quick movement from field to field.

The Fendt Twister Hydro models are equipped with the isosceles Super C tine as standard. The Super C tine has been specially developed for high performance, optimum combing effect and special durability. The special manufacturing process enables stability with simultaneous elasticity, so that the tine works stably in changing conditions and withstands high loads. The rotor head and the complete drive train are designed for easy maintenance. A night-swath transmission is also available as an option for hay farms, in order to turn the forage as gently as possible.