The fifth generation of the 800 Vario, with three models (Fendt 826, 829 and Fendt 832 Vario), sits at the power range from 260 to 320 hp (191 – 235 kW) in the Power+, Profi and Profi+ versions. The completely new developed series has the Fendt DynamicPerformance (DP) added power concept is available for all models and additionally releases 23 hp (17 kW) each when its required due to secondary consumers such as the cooling fan, oil pump or air-conditioning compressor. Under all operating conditions, the machine will always provides enough power for the main consumers such as the travel drive which increases productivity.

| Model | Max. Power | Maximum power with DP according to ECE R120 | Max. Torque (Nm) |

Fendt 826 Vario | 260 hp (191 kW) | 283 hp (208 kW) | 1,450 |

Fendt 829 Vario | 290 hp (213 kW) | 313 hp (230 kW) | 1,550 |

Fendt 832 Vario | 320 hp (235 kW) | 343 hp (252 kW) | 1,680 |

Designed to meet the requirements of contractors and large agricultural farms worldwide, the focus of the new development was on a powerful and manoeuvrable overall package with a high payload, low fuel consumption in various conditions and comfortable operations. The Fendt VarioDrive , the latest generation of the Vario transmission paired with the efficient 6-cylinder CORE80 engine with 8.0 litres cubic capacity, specially developed for Fendt, is pivotal for the low fuel consumption. Exhaust gas after-treatment takes place via a diesel oxidation catalytic converter (DOC), diesel particulate filter (DPF) and with selective catalytic reduction (SCR) without exhaust gas recirculation. It meets all the emission standards required worldwide. In the EU, this is the emission standard Stage V.

The CORE80 engine is already approved for HVO100 and other fuels according to DIN 15940. Operating with HVO can significantly reduce the machine's CO2 footprint. There are also maintenance-free hydraulic tappets built into the engine. The first engine oil service occurs at 500 h, so the initial 50 h interval has been omitted. Technical optimisations increase the replacement interval of the transmission oil from 2,000 to 4,000 operating hours or 4 years. This further reduces maintenance costs.

Manoeuvrable thanks to Fendt VarioDrive

The single-stage Fendt VarioDrive drivetrain with permanent, independent four-wheel drive was first introduced in 2014 with the Fendt 1000 Vario and is now available for the first time in the Fendt 800 Vario series. This enables maximum tractive power with high soil protection on different subsoils. In addition, there is no need for manual shifting when switching between field and road. VarioDrive drives the front and rear axles independently of each other and distributes the power dynamically. Another advantage is the so-called pull-in turn effect. Thanks to the pull-in turn, the independently driven front axle actively pulls the machine into the turn without torsion and the Fendt 800 Vario achieves a particularly small turning circle.

Fendt iD low speed concept saves fuel

All tractor components such as engine, transmission, hydraulics and cooling were now designed for the so-called “high torque – low engine speed” principle. The Fendt iD low-speed concept allows the Fendt 800 Vario to achieve high torque and saves fuel at low engine speeds. The rated engine speed is only 1,700 rpm. In the main working range, the speed is a quiet 1,100 to 1,400 rpm. The speed of 40 km/h is reached at 950 rpm, 50 km/h at 1,200 rpm, and the top speed of 60 km/h at 1,450 rpm. The maximum torque of 1,680 Nm is available on the top model Fendt 832 Vario from 1,200 rpm and ensures high tractive power and acceleration with minimal specific fuel consumption.

High payload for teams

The payload of a tractor decides which implement combinations are possible with the tractor. The low operating weight of 9.9 t with a permissible overall weight of up to 17.5 t with an approval for 40 and 50 km/h results in a payload of 7.6 t. This enables legal work in the team with a precision seed drill with a front tank or the legal transport of a front-rear mower combination. In addition, there are flexible options for ballasting at the front and on the rear wheels so that the machine runs optimally in field or road use.

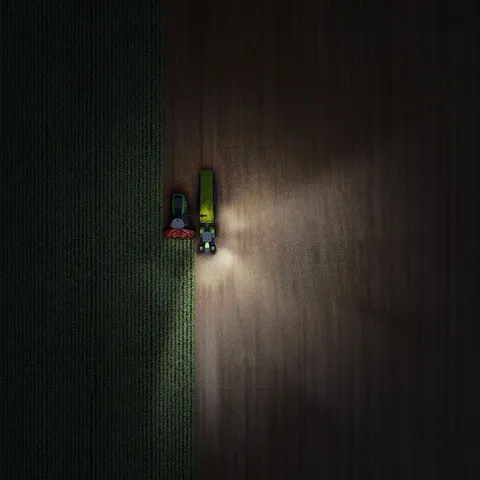

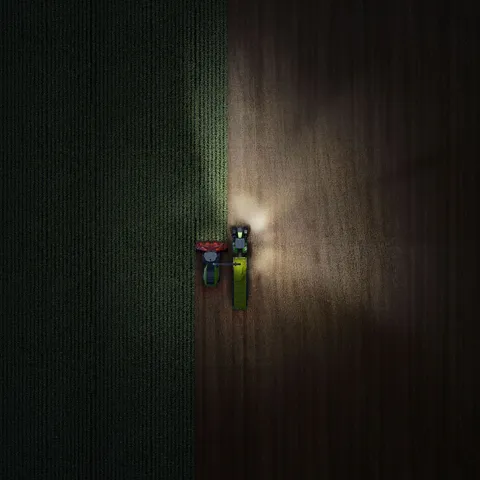

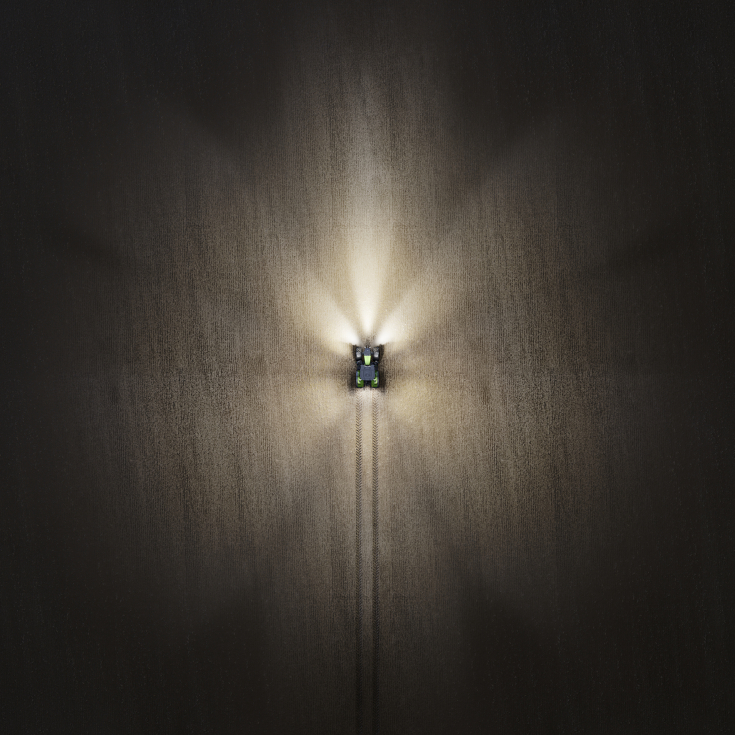

Brings light into the darkness with up to 114,700 lumens

The tractor cab is central to driving comfort: the seat, air-conditioning, lighting and viewing angles influence the working comfort and the result of the work. With the Fendt 800 Vario series, Fendt is presenting the new tractor cab with exclusively developed lighting concept for the first time. Work such as sowing, harvesting, pesticides or winter service are highly dependent on the weather. For example, if the work lasts until night due to a threatening weather swing, the tractor's lighting can decide whether the work can continue.

The view to the front as well as the view of the implement and the processed areas are central to continuously monitor the work results. The LED spotlights are available in two equipment variants: Vision and UltraVision. In both variants, eight or 12 spotlights can be installed in the cab roof. In the UltraVision variant, the tractor illuminates the area with 4,400 lumens per spotlight and the spotlights are dimmable in 5 stages. This function is especially useful when several machines are working on one area. The Vision equipment option offers 1,000 lumens per spotlight. All spotlights, including the rotating beacon, are firmly installed in the cab roof and placed in agricultural use for optimum illumination and glare-free working. This increases comfort and safety.

UltraVision stages

Easy and fast operation

Up to four individual profiles can be stored for convenient and quick operation of the work lights. For example, if the tractor is driving to the left of the field chopper, the driver can dim the light on the side of the chopper, while brightly illuminating the rest of the environment so as not to glare the chopper. The configuration can also be mirrored with one click. This function is helpful when the chopper driver is driving along side the forage harvester. Also new is the independent control of the individual spotlights. If the weather changes due to fog or rain, the light intensity can be adjusted quickly.

The machine can be equipped with Tech Rails on the C-pillar for the installation of supplementary work lights or sensors in the future. The Tech Rails, including their own cable entry, provide space for up to two work lights per side. This means that the machines are prepared for future requirements.

The new, optional Fendt GroundVision drawbar lighting illuminates the area directly at the rear of the machine. On the one hand, the area directly in front of the implement and in front of it is illuminated in field use, and on the other hand, it simplifies the coupling and uncoupling of implements in the dark. The lights are integrated at the lower end of the rear fenders.

In addition, the well-known spotlight options are available on the tractor's chassis and complete the lighting concept. These include:

- Work lights on top of the bonnet

- Daytime running lights (standard)

- Low beam and high beam

- Corner Lights (standard)

- Auxiliary lights on the mirror frames

- New indicator and position lights

- A total of 4 work lights on the A-pillar

- Entrance lighting

- Rear lights

- Work lights on the rear fenders

- Lighting for marking for wide loads

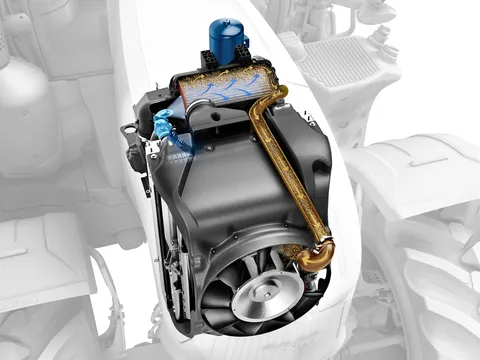

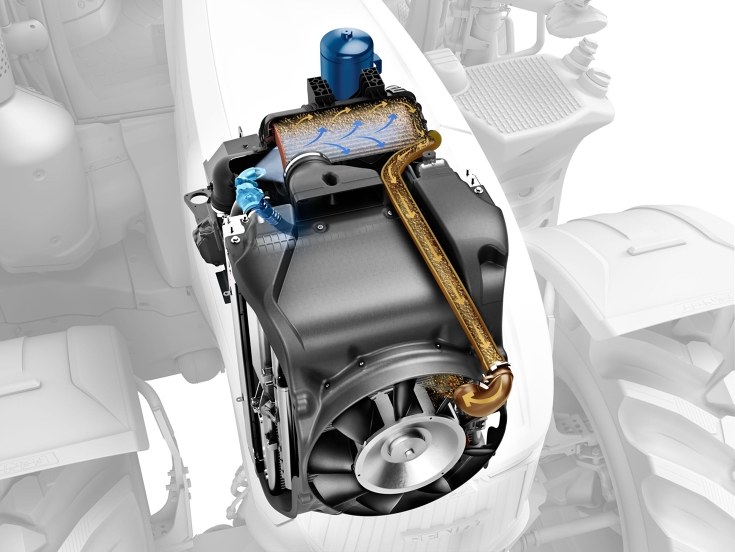

Efficient ventilation, cooling and filtration

As standard, the Fendt 800 Vario is now also equipped with the exclusive Concentric Air System (CAS) ventilation & cooling concept. The fan can be optionally equipped with a reverse function. In addition, a self-cleaning air filter including automatic control is optionally available for the CORE80 engine. If the engine air filter is cleaned automatically, drivers can carry out their field work without interruption, and regular cleaning increases the longevity of the machine and ensures optimum fuel consumption. This DLG awarded system is already known from the Fendt 1000 Vario. Now this option is always offered together with the automatic dust extraction for the cab air filter. In this system, the cab air filter is continuously and automatically passively cleaned by vacuum and a cyclone separator. This function has been specially developed for use in hot or particularly dusty conditions, such as cultivators in dry weather. It reduces daily maintenance and increases the air quality in the cab.

Reversible fan for the Fendt 800 Vario

Self-cleaning engine & cab air filter in the Fendt 800 Vario

More comfort in the cab

Long working days place high demands on the driver, which is why the tractor cab offers numerous equipment options for greater working comfort. All equipment lines have the FendtONE workstation with armrest and up to three display areas (Profi and Profi+). Optional footrests are even added on the steering tower and the side console for relaxed leg position.

If the Fendt 800 Vario is used in winter service, the optional, heated laminated safety glass (LSG) front window makes visibility easier. The front window heating accelerates the defrosting, prevents renewed ice formation and fogging in case of snowfall. Thanks to its special composite process, it can better withstand contact with foreign matter. The glass with integrated splinter protection remains intact in the event of damage, so the driver is protected against injuries. In addition, the laminated glass front window dampens noise particularly well.

If the Fendt 800 Vario is used with an implement in the rear, such as a wood chipper or forestry mulcher, all control elements can be rotated by 180 degrees thanks to the optional reverse drive control. The reverse drive control thus allows a direct view of work implements. In addition to the 4-speed PTO, there is a separate PTO with 540/900/1000 rpm speeds, for example, for use with a wood chipper, to make optimum use of the motor's speed range.

The new, electrically adjustable “Super Comfort Seat Titanium Leather” has numerous options for high seating comfort. The driver adjusts the seat height and position as well as the backrest angle electrically via a lever on the side of the seat. When changing out drivers, they can create personalised seat profiles and call up these user profiles in the FendtONE onboard.

The comfort functions consist of:

- Multi-stage seat climate control

- Multi-stage seat heating

- Four-way lumbar support

- Adjustable side bolsters

- Massage function with three different programs

- Memory function for different users

Even when used at high outside temperatures, the performance of the air-conditioning system as standard, provides automatic comfortable temperatures in the cab. There is also a new compressor cooler with a volume of 12 litres. Drinks and food can be cooled (0-16°C). For high air quality in dusty operating conditions, the optional automatic dust extraction provides for the cab air filter.

Another new feature is the integration of Apple CarPlay into the Fendt infotainment via cable or Bluetooth. Already known from the automotive sector, operation is carried out via the terminal on the armrest. The software will be rolled out in June 2026.

Complex implements such as precision seed drills with integrated fertiliser tanks and high separation rates place high demands on the hydraulic system of a tractor. The Fendt 800 Vario now has a maximum of six hydraulic control units in the rear and two in the front (6+2). A maximum of 4 control units in the Power+ equipment line are available in the rear and one in the front (4+1) or five control units in the rear (5+0). Customers can also choose between three hydraulic pumps: 165 l/min, 220 l/min and for consumers with varying requirements in terms of oil quantity and pressure, a double pump system with a maximum flow capacity of 385 l/min (165 + 220 l/min) is available. If the implement transfers a particularly high amount of heat into the hydraulic system or if the tractor is used in hot regions, an optional additional hydraulic oil cooler improves the hydraulic oil cooling capacity. In the rear, the optional FFC flat-sealing couplings for control units and the Power Beyond connection prevent the dirt ingress into the system as well as leakage oil and reduce pressure losses. The relieving rear power lift transfers weight from the implement to the tractor for optimum ground hugging, for example when working with milling machines or mulchers. The lift assist for the top link takes over part of the weight from the top link and supports the work ergonomics when mounting implements.

The Fendt 800 Vario achieves a high overall productivity thanks to its versatility. Features such as VarioDrive, top speed of up to 60 km/h, the high payload, the comprehensive chassis and safety concept, the optional exhaust brake in conjunction with the hydraulic auxiliary brake, the self-centring Fendt Reaction Steering, Fendt Stability Control (FSC) or the Trailer Brake Assistant (TBA) characterise the series in transport. The trailer brake assistant displays its advantages, for example, in the team with an attached sprayer or a pneumatically braked trailer in the chopping chain. Then this keeps the team in line even in curves on the slope and prevents it from jack-knifing or drifting. The optional automatic parking brake and numerous axle and tyre options round out the package.

In the cab, drivers can make numerous adjustments individually and directly via the terminal. This includes the setting of the seat, mirrors and lights, but also the control of radio and telephone. This supports driving comfort during long transport operations.

For large areas in grassland

On large grassland areas, farmers and contractors need powerful technology with a high payload that works in a soil-friendly manner. They use suitable time windows efficiently even in unsafe weather conditions. Complex mowers combinations, such as a Fendt Slicer front mower and Fendt Slicer 1010 RCB PRO rear mower with conveyor belt, require sufficient payload to legally transport the mowers. The low empty weight of the machine, the optionally cooled front PTO, the Fendt VarioGrip tyre pressure regulation system and the full range of FendtONE onboard characterise the Fendt 800 Vario in grassland use. While the independent four-wheel drive from Fendt VarioDrive protects the sward and avoids forage contamination, Fendt VarioGrip reduces ground pressure. In addition, a position control and relief control for the front power lift is optionally available for the Fendt 800 Vario. For an optimal cutting pattern, the cutter bar is guided permanently with a constant pressure, regardless of the ground contour. Options such as GroundVision drawbar lighting or the LSG front window increase safety.

Numerous axle and tyre options

For the Fendt 800 Vario series, there are numerous options for track width, tyres and the Fendt VarioGrip tyre pressure regulation system. Depending on the local requirements, customers can now order the tractor as standard with a flange or a stub axis (3.0 m or 2.50 m). The 2.50 m stub axis is now also approved for 60 km/h and is the basis for the optional dual wheel hub. The dual wheel hub is a coupling system for dual wheels that allows the transfer of higher forces. The dual wheel hub transmits the power safely through the axles instead of the rims as in other systems. The track width of the dual wheels is adjusted in the 2.5 m version via flexible intermediate pieces (spacers).

The fully integrated Fendt VarioGrip tyre pressure regulation system increases the footprint of the tyres and brings the weight of the tractor to the ground particularly gently. At the same time, traction increases and fuel consumption decreases. This increases the overall productivity of the machine and soil fertility. In the terminal, the driver can comfortably control the tyre pressure. Fendt VarioGrip is optionally available directly from the factory for both the flange and the stub axles, for dual tyres and also with wheel weights.

Customers can choose between the front weights with 870 kg, 1.25 t or 1.8 t as required. Fendt newly offers an additional front weight of 2.2 t. The high material density of the front weights reduces the overall volume and thus enables relatively compact dimensions. The machine extends less far forward when loaded, and the weight contours leave the low beam and high beam lights unobstructed.

Tyre options

Standard tyres in DE | Max. Tyres metric (dual) | Max. Tires Row Crop (dual) | |

| Fendt 826- 832 Vario | Fendt 826 Vario | Fendt 826 Vario | |

| Front | 600/65 R34 | VF710/55 R34 | VF420/85 R34 |

| Inner | VF620/75 R30 | VF420/85 R34 | |

| Outer | VF620/75 R30 | VF420/85 R34 | |

| Rear | 710/75 R42 | VF900/60 R42 | VF480/80 R50 |

| Inner | VF710/75 R42 | VF480/80R50 | |

| Outer | VF710/75 R42 | VF480/80R50 |

At home worldwide

There is also a large market for tractors in this performance class outside of Europe. For these regions, the track width of 60 inches, various tyre options and variants in the rear are available. The choice between a stub or flange axle combined with the option for dual tyres covers the global requirements. In regions such as South America or Australia, there are often long periods of drought. Customers from these regions can equip the Fendt 800 Vario with the self-cleaning air filter including automatic control and automatic cleaning of the cab air filter for use in particularly dusty conditions.

New: Guidance system at up to 40 km/h

The speed of the team can be a limiting factor in use with implements such as a fertiliser spreader or a pesticide sprayer. Until now, the use of a guidance system was limited to a top speed of 25 km/h. With the Fendt 800 Vario series, Fendt offers a new guidance system option: Fendt HighSpeed Guidance. This is a further development of the classic guidance system, which can be used at up to 40 km/h in agricultural areas. It is particularly interesting for farms with large and predominantly flat structures, such as in North or South America, as well as in Australia, which carry out pesticide and fertilisation measures at high speeds. In Europe, the areas are often structured smaller, and here, too, speeds above 25 km/h can make an important contribution to time-critical field processing in tight time windows.

Versatile in non-agricultural use

Attachments such as snow blowers or forestry mulchers are mainly used under challenging conditions. With numerous tyre options, high payload and hydraulic power as well as high torque and a new lighting concept, the Fendt 800 Vario is designed for exactly this kind of application. The reverse drive control and Fendt VarioDrive further facilitate work in non-agricultural sectors. For use in winter service or with a side mulcher, a front window wiper on the right side is standard for better visibility ex works. The laminated glass front window and LED headlights ensure greater safety and a high level of working comfort.

The Fendt 800 Vario Gen5 can be ordered from autumn 2025.