The Fendt implement carrier's so called “one-man system” revolutionised agriculture in 1957, establishing Fendt as the leading manufacturer of system tractors. GT is the abbreviation for the German term „Geräte-Träger”, which means implement carrier.

The ability to mount the attachments as a single person and combine several work steps, such as hoeing and harrowing, were decisive factors. Farmers also appreciated the four mounting areas — at the front, rear, semi-mounted, and mid-mount, between the axles — which allowed for combinations such as spray booms and tanks. These flexible application options increased utilisation and productivity, making farmers less dependent on additional personnel.

Even today, farmers must complete their work within ever shorter timeframes and availability of labor is limited. Accordingly, demand for advanced automation, autonomy and robotics solutions is continuously growing.

Fendt has been developing corresponding technologies and concepts for many years to utilise robotics, autonomy and artificial intelligence in agriculture and develop economical, practical, and sustainable solutions.

For several years, mechanical weed control in row crops has been experiencing a renaissance, not only in organic farming but also increasingly in conventional farming, especially for root crops. The development is driven by resistance of weeds and the social desire to reduce pesticide use as much as possible.

Precise row guidance is essential for alternative crop protection methods. This is the only way to hoe close to each plant with maximum precision. The growing number of crossings at slower speeds, coupled with the higher costs of intelligent attachments per metre of working width, further emphasises the need for assistance systems and autonomous technology.

An autonomous system for existing agricultural implements

Fendt Xaver GT

In the long term, the standard tractor will continue to play a central role, particularly when used in conjunction with large and heavy implements and for transport.

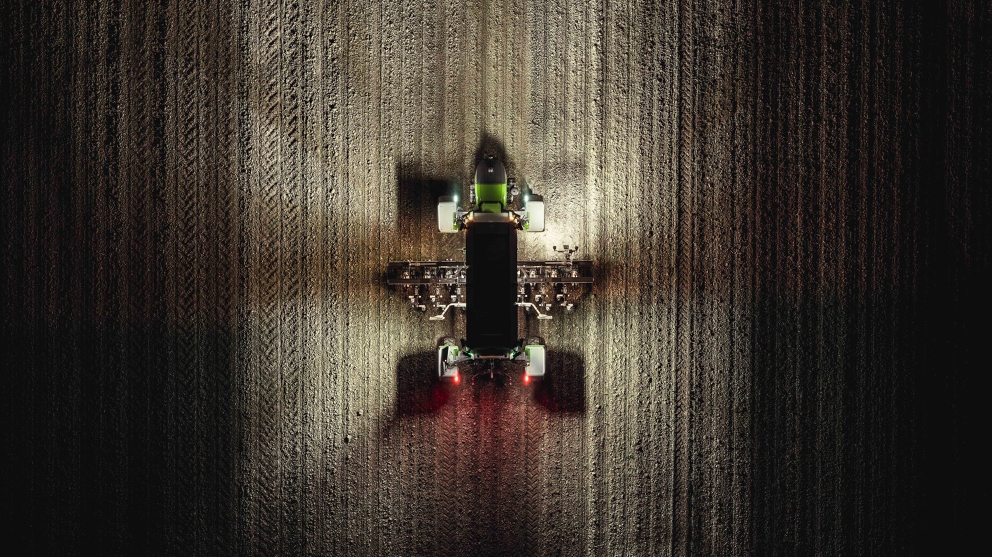

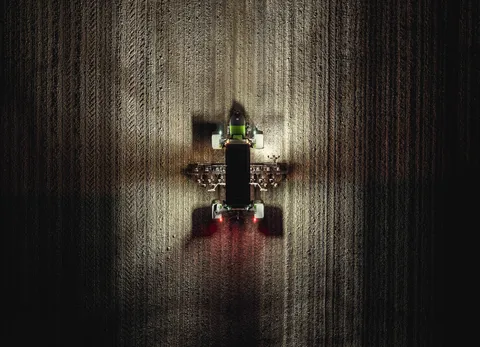

The Fendt Xaver GT system carrier vehicle is a perfect fit here. Thanks to standardised interfaces such as three-point mounting and hydraulic connections, it can work with around the crop cycle and perform a wide range of lighter fieldwork tasks precisely and safely in autonomous mode if required. The Fendt Xaver GT's design makes it more flexible to use, achieving high utilisation times and cost-effectiveness throughout the agricultural year.

Its light unladen weight, combined with the mid-mount implement position in the inter-axle area, enables a minimal total weight of the vehicle-implement combination with consistent axle load distribution. Soil compaction is reduced to a minimum when the Fendt Xaver GT makes multiple passes.

A system carrier vehicle for various applications

The Fendt Xaver GT was designed as an autonomous system carrier vehicle with mid- and rear-mounting positions. The mid-mount position also has a power lift, built on a sliding frame. Both three point linkages have a lifting capacity of 2.0 tonnes. The 3.4 m wheelbase ensures smooth and stable driving. The design of the Fendt Xaver GT was inspired by the popular Fendt tool carriers (GT) from the Fendt history.

Depending on practical requirements and needs, the track width of the Fendt Xaver GT can be adjusted to 1.5 m, 1.8 m, 2.0 m or 2.25 m. This covers the majority of European and international cultivation systems, enabling the Fendt Xaver GT to work in areas with existing track lines. With a ground clearance of 50 cm, it can also be used in later growth stages without damaging plants. These features make it possible to cultivate fields using standard tractors in alternation with the Fendt Xaver GT. For instance, soil cultivation before sowing sugar beet can be carried out using a tractor. The Fendt Xaver GT then takes care of sowing, hoeing, harrowing and other crop care tasks. Harvesting is then carried out with a conventional sugar beet harvester. This means that the Fendt Xaver GT can autonomously perform monotonous, time-consuming and repetitive tasks, while skilled workers can carry out time-critical and complex tasks in parallel.

On the road, Fendt Xaver GT transforms into a trailer that can be easily transported to the field with a tractor. It has a special 'transport mode' for this purpose. Once in the field, one person can use the remote control to steer the field robot into position and activate working mode.

Powered by a diesel hybrid

The Fendt Xaver GT's powertrain is designed as a serial hybrid with two buffer batteries. The 25 kW (48 V) generator is powered by a diesel engine. A battery system with a capacity of 9 kWh provides additional boost power for short-term needs.

The four independently steerable wheels are driven by electric motors, enabling the Fendt Xaver GT to navigate with particular precision. In the field, the Fendt Xaver GT operates at a speed of up to 10 km/h. Different steering modes can be selected depending on the application. As well as typical Ackermann steering, farmers can use four-wheel steering to achieve smaller turning radii at the headland, and superimposition mode (crab steering + four-wheel steering) to counteract downhill forces on slopes.

The Fendt Xaver GT's safety system has a two-stage design. The tactile safety system, including geofence and status monitoring, forms the basis for safe working in accordance with all regulatory requirements. To maximise availability, it also features an intelligent, proactive environment perception system with lidar sensors and cameras. These detect potential obstacles at an early stage and automatically initiate countermeasures.

The user interface is based on FendtONE with the familiar Fendt operating concept and also allows remote access to the machine via mobile phone, tablet or PC. Alongside advanced route planning and satellite-based guidance, the Fendt Xaver GT features camera and lidar systems that use artificial intelligence to recognise features such as plants, rows and tramlines. This enables precise navigation along crops, even when satellite reception is poor due to shading, for example.

Autonomous hoeing in the mid-mount area

In the mid-mount position, for instance, hoeing with a sliding frame can be executed with particular precision. Mounting the hoe centrally between the axles significantly reduces the effects of steering on the lateral movement of the implement compared to mounting it at the rear. This increases precision, enabling hoeing to take place very close to the crops.

Robust row detection forms the basis for reliable control of the sliding frame, even in windy conditions or on uneven terrain. To this end, Fendt has developed RowPilot in collaboration with PTx.

More about ROWPILOT