VarioGuide – always on track:

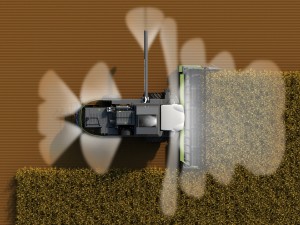

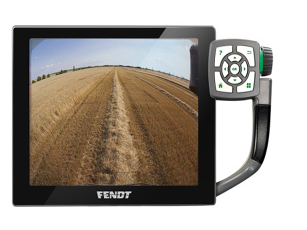

The optional VarioGuide uses the latest technology to guide your machine precisely through the crops. This gives you higher threshing performance by reducing unnecessary passes and optimising the field division. The integrated automated steering system is adjusted in the Varioterminal with just a few clicks.

Identify areas of potential: Yield mapping:

Adding location data to the yield reading gives you a useful map view with subsection-specific yields using a field database. This helps you quickly identify the strengths and potentials of each run-out and coordinate your follow-up work where it is needed. A separate satellite receiver is required for yield mapping.